Defoaming device for high viscosity liquid product

A technology for defoaming devices and liquid products, applied in the direction of foam dispersion/prevention, etc., can solve the problems of large energy consumption, large resistance, low defoaming efficiency, etc., and achieve the effect of easy operation, simple structure and high defoaming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

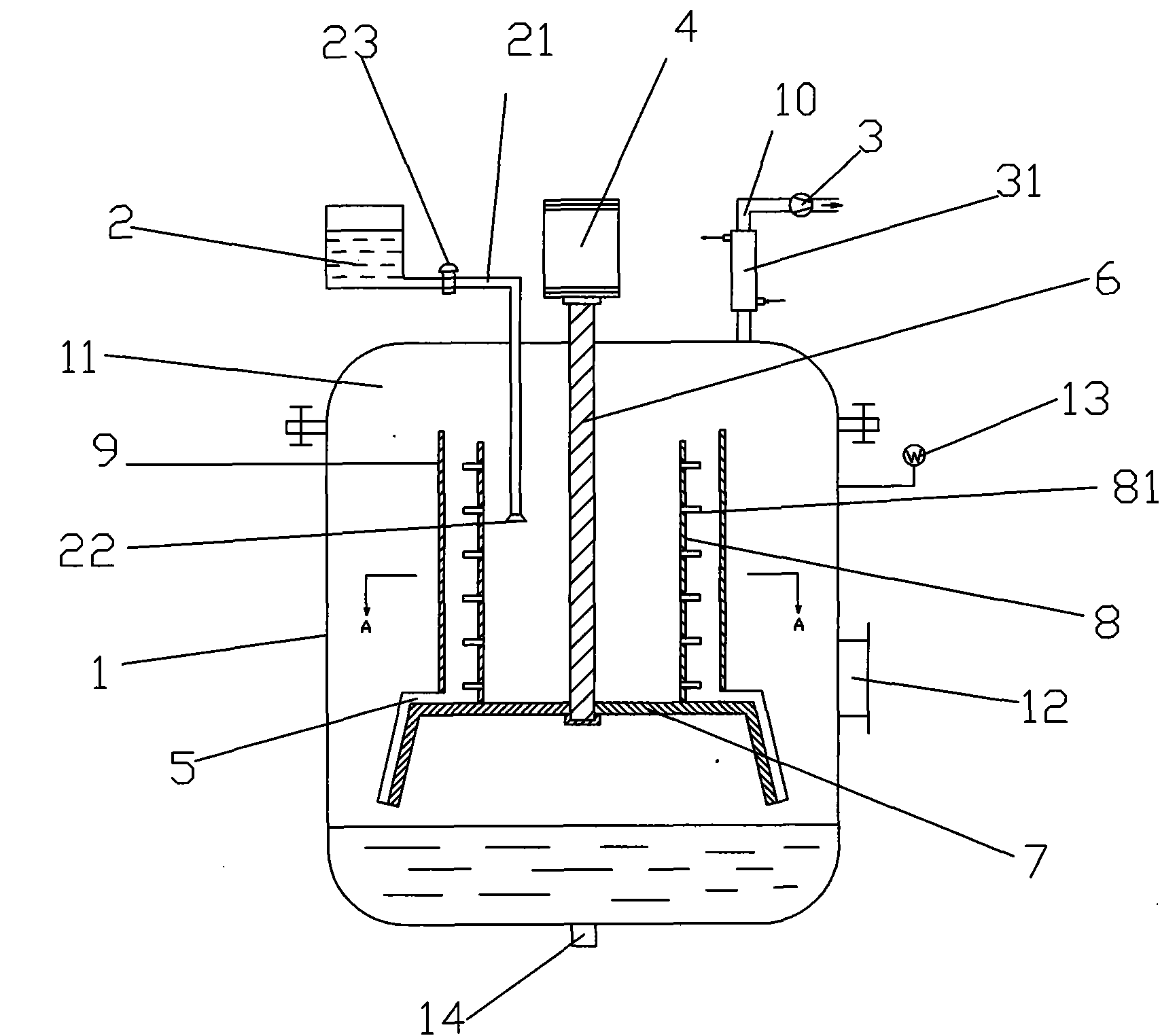

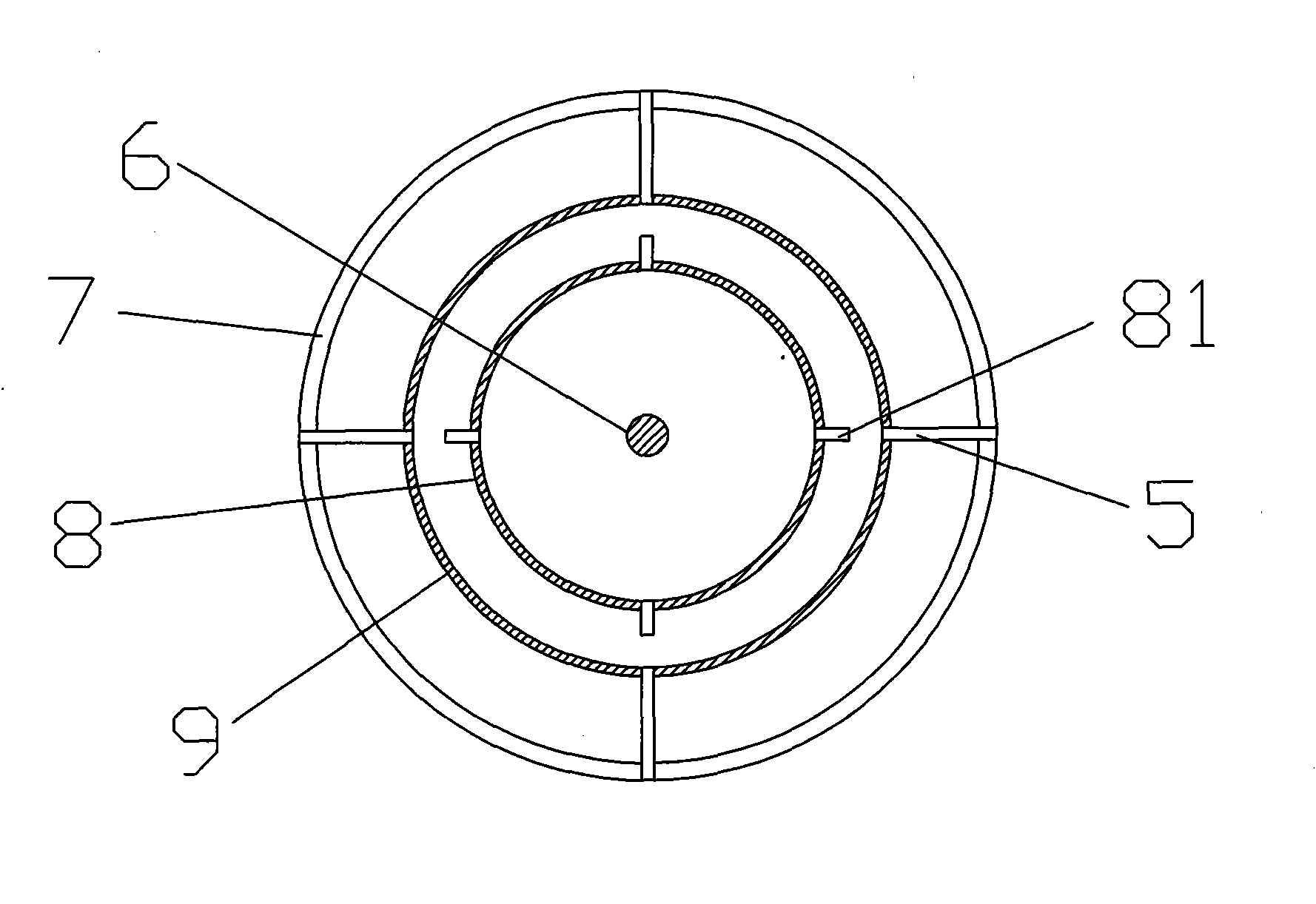

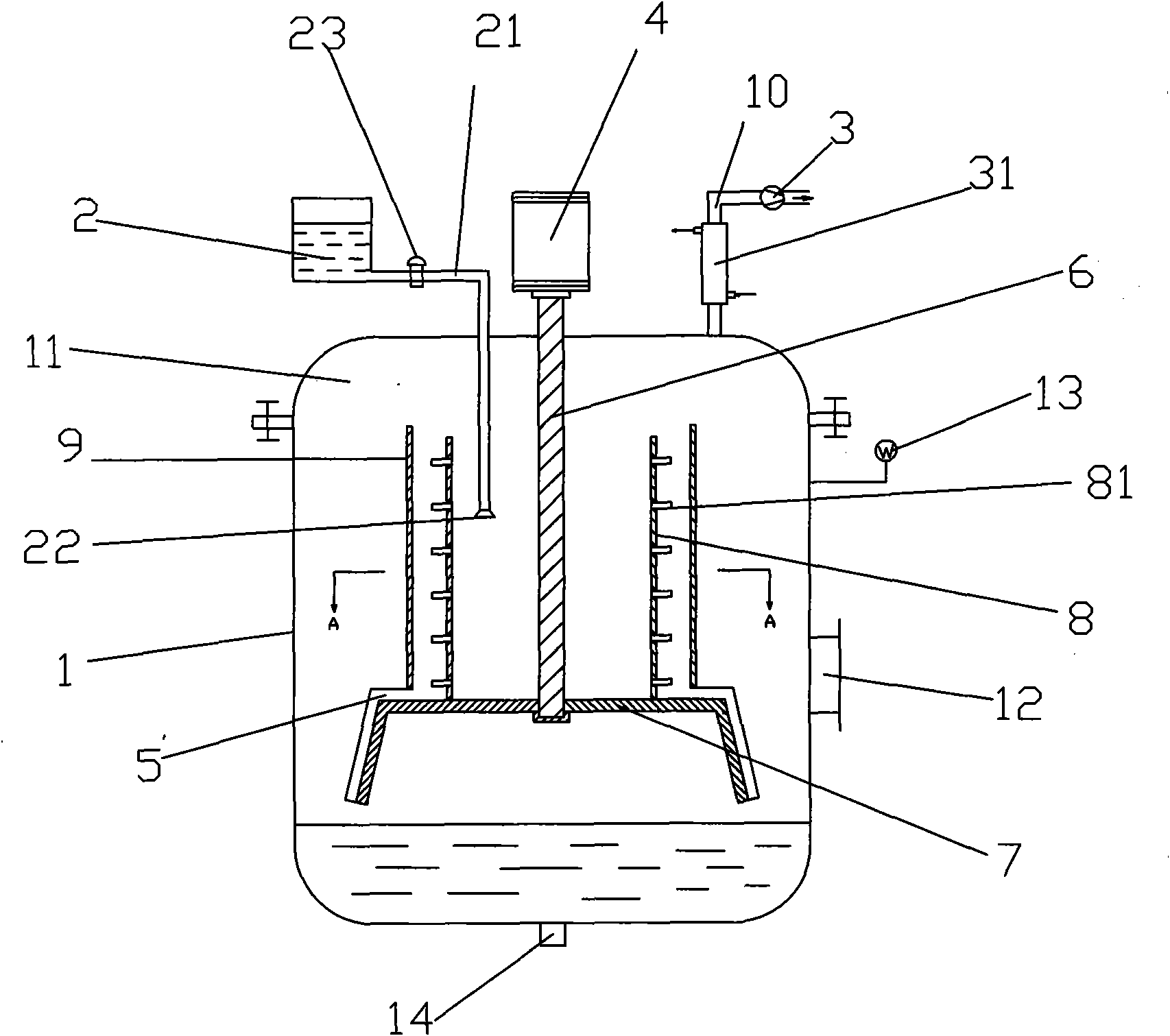

[0027] A defoaming device for high-viscosity liquid products, which mainly includes a vacuum stirring tank 1, a storage tank 2, a vacuum pump 3 and a motor 4. The vacuum stirring tank 1 has a sealable cavity 11, and the inside of the cavity is vertically A stirring shaft 6 is provided; the upper end of the stirring shaft 6 is fixedly connected with the rotating shaft of the motor 4, and the motor 4 can drive the stirring shaft 6 to rotate; Inclined downward; on the horizontal part of the metal bottom plate 7, a cylindrical filter 8 and a cylindrical partition 9 are respectively spaced around the stirring shaft 6, and a plurality of metal tubes 81 are arranged on the filter 8, and the metal tubes Inner diameter ≥ 5mm; a diversion tube 5 is provided between the bottom of the partition and the metal bottom plate 7, the diversion tube extends along the plane of the metal bottom plate to the downwardly inclined part of the edge of the metal bottom plate, and the inner diameter of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com