Method for preparing foam killer

A defoamer and catalyst technology, which is applied in the field of defoamer preparation, can solve problems such as high viscosity, affecting the use of defoamers, and affecting defoaming performance, and achieves the effects of low cost, increased application range, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

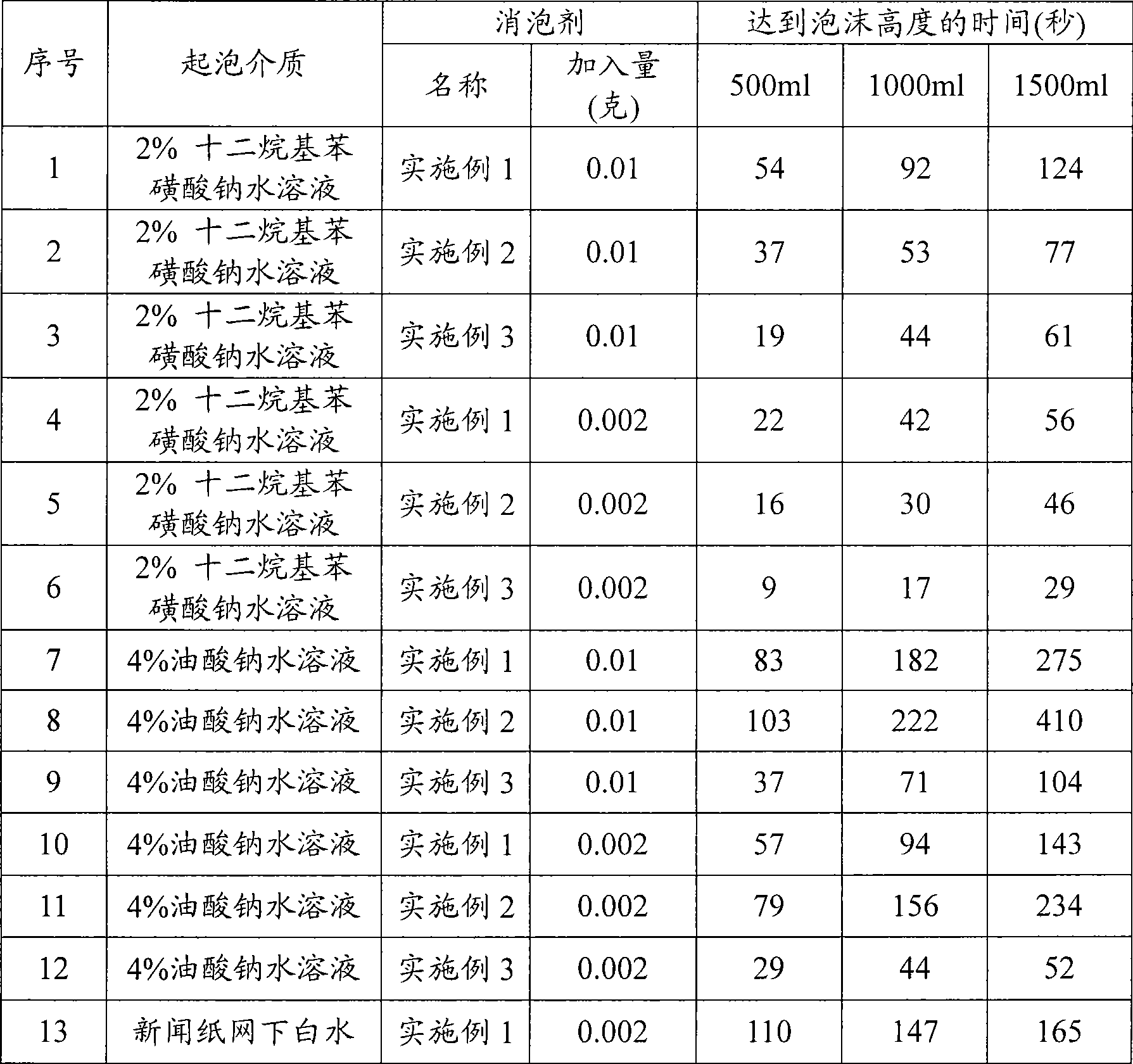

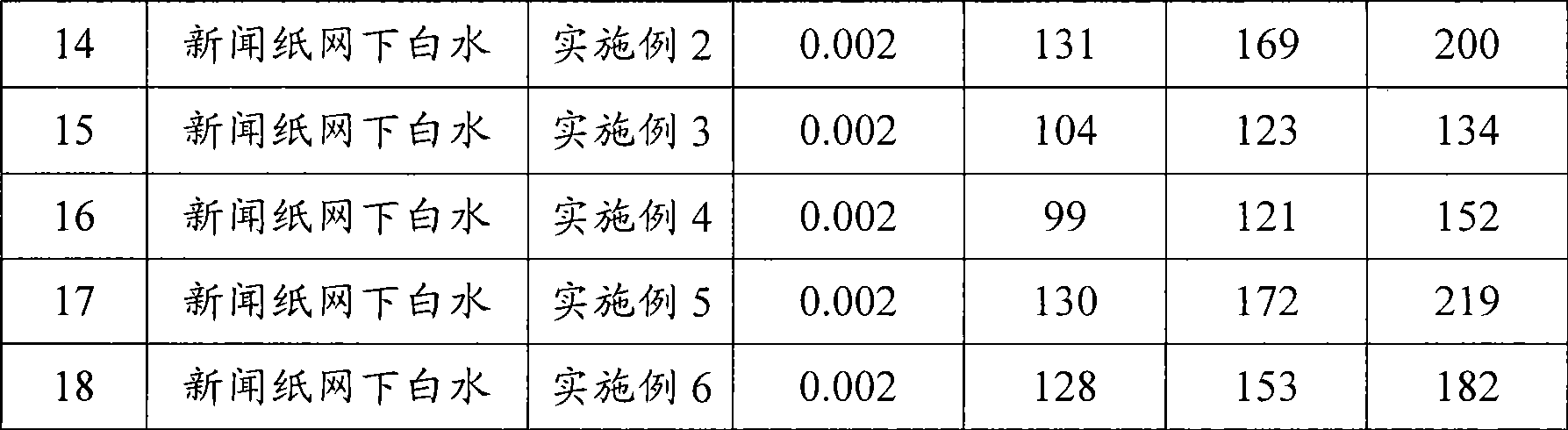

Examples

Embodiment 1

[0017] In a pressure-resistant reactor with stirrer, thermometer, and condenser, add 184 grams of glycerin (2mol), 6.84 grams of potassium hydroxide aqueous solution (1.84 grams of potassium hydroxide), heat up to 160 ° C, and stir for 1 hour Afterwards, about 5.5 grams of water are distilled from the condenser; continue to heat up to 250 ° C, stir and react for 3 hours, then distill about 24 grams of water from the condenser to obtain polyglycerol; calculate from the amount of water distilled in the second heating reaction, At this time, the average degree of polymerization of polyglycerol is about 3.

[0018] Lower the temperature of the obtained reaction product to 120°C, add 5610 grams of propylene oxide and 2200 grams of ethylene oxide in turn to carry out ring-opening polymerization reaction, after the reaction, neutralize and decolorize to obtain polyglycerol polyoxypropylene polyoxyethylene ether , its hydroxyl value is 25mgKOH / g.

[0019] Take 500 grams of the above-...

Embodiment 2

[0021] In a pressure-resistant reactor with stirrer, thermometer, and condenser, add 184 grams of glycerin (2mol), 6.84 grams of potassium hydroxide aqueous solution (1.84 grams of potassium hydroxide), heat up to 200 ° C, and stir for 1 hour Finally, distill about 5.5 grams of water from the condenser; continue to heat up to 265 ° C, and distill about 30 grams of water from the condenser after 4 hours to obtain polyglycerol; calculate from the amount of water distilled in the second heating reaction, at this time The average degree of polymerization of polyglycerol is about 6.

[0022] The obtained reaction product was cooled to 120°C, and 2800 g of propylene oxide was added to carry out ring-opening polymerization reaction. After the reaction, it was neutralized and decolorized to obtain polyglycerol polyoxypropylene ether with a hydroxyl value of 53 mgKOH / g.

[0023] Get 500 grams of the above-mentioned polyglycerol polyoxypropylene ether, add 36.8 grams of palmitic acid, a...

Embodiment 3

[0025] In a pressure-resistant reactor with stirrer, thermometer, and condenser, add 184 grams of glycerol (2mol), 6.78 grams of potassium hydroxide aqueous solution (1.78 grams of potassium hydroxide), heat up to 180 ° C, and stir for 1.5 hours Finally, about 5.5 grams of water are distilled from the condenser; continue to heat up to 235 ° C, and after stirring for 4.5 hours, about 24 grams of water are distilled from the condenser; The average degree of polymerization is about 3.

[0026] Lower the temperature of the obtained reaction product to 120°C, add 2200 grams of ethylene oxide and 1120 grams of propylene oxide in turn to carry out ring-opening polymerization reaction, after the reaction, neutralize and decolorize to obtain polyglycerol polyoxyethylene polyoxypropylene ether , its hydroxyl value is 55mgKOH / g.

[0027] Take 500 grams of the above-mentioned polyglycerol polyoxyethylene polyoxypropylene ether, add 40.6 grams of stearic acid, add 5 grams of catalyst sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com