Defoaming composition of polyether modified siloxane

A polyether modification, siloxane technology, applied in the directions of foam dispersion/prevention, chemical/physical process, dissolution, etc., can solve problems such as prolonged fermentation time, and achieve simple preparation process, long-lasting foam suppression effect, and defoaming efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

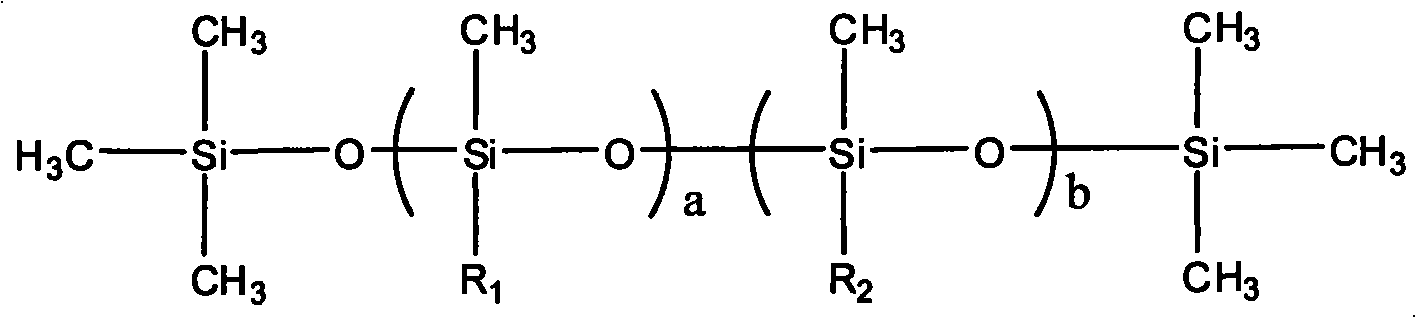

[0024] Mass fraction meter, in 100 parts of polydimethyl silicone oil (Shanghai Huipu Industrial Chemicals), add 8 parts of ethylene oxide, propylene oxide and propylene glycol condensate (Germany BASF company PluronicL-62), in airtight vacuum reactor Add 0.01 parts of chloroplatinic acid as a catalyst, 10 parts of isopropanol as a solvent, react at room temperature for 2 hours, transfer to a fractionation tower to remove the catalyst with activated carbon, and heat and fractionate in a rectification column to obtain polyether modified non-toxic siloxane (I).

[0025] 80 parts of the obtained polyether modified siloxane (I), 10 parts of silicon dioxide particles (U.S. Evonik R106), 2.5 parts of sodium dodecylbenzenesulfonate, 7.5 parts of ethanol, at normal temperature The product was obtained under stirring for 30 minutes, which was recorded as A-1.

Embodiment 2

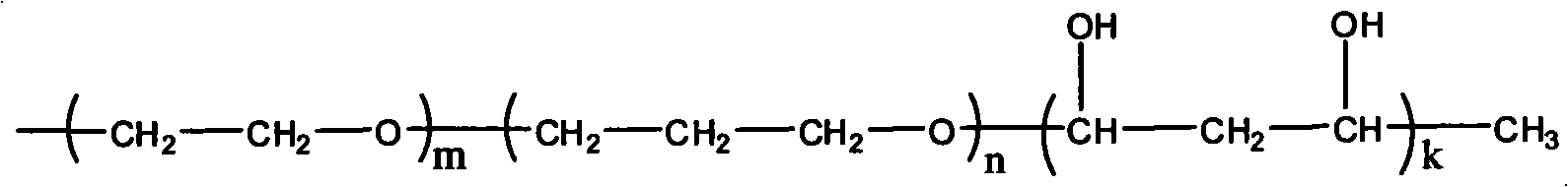

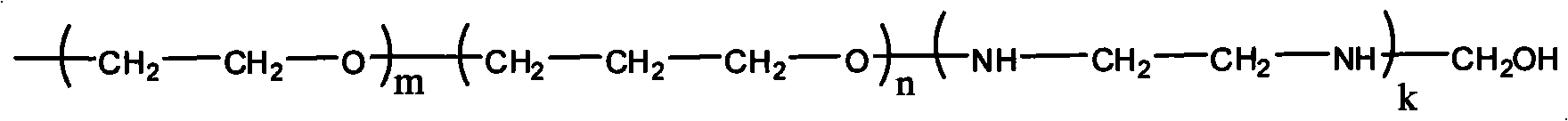

[0027] In terms of mass fraction, add 4 parts of ethylene oxide, propylene oxide and ethylenediamine condensate (Tetronics of German BASF company) to 100 parts of polydimethylsilicone oil (DC 350 of U.S. Dow corning company), and react in a closed vacuum Stir in the device, and add 0.01 part of chloroplatinic acid as a catalyst, 10 parts of toluene as a solvent, react at room temperature for 2 hours, add 0.2 parts of alkyl ethoxylamine (Berol OX-91 of Akzo Nobel Company), Transfer to fractionation tower and use active carbon to remove catalyst, heat fractionation in rectification column to obtain polyether modified siloxane (I).

[0028] 60 parts of obtained polyether modified siloxane (I), 20 parts of silicon dioxide particles (U.S. Evonik R106), 4.0 parts of sodium lauryl phosphate, 15 parts of ethanol, 1.0 parts of methylol The cellulose was stirred at room temperature for 30 minutes to obtain the product, which was recorded as A-2.

Embodiment 3

[0030] In terms of mass fraction, in 100 parts of polydimethylsilicone oil (DC 200 of U.S. Dow corning company), add 8 parts of ethylene oxide and propylene oxide condensation (Tergitol 15-S of U.S. Dow company), in a closed vacuum reactor Stir, and add 0.03 parts of chloroplatinic acid as a catalyst, 10 parts of toluene as a solvent, react at room temperature for 2 hours, transfer to a fractionation tower to remove the catalyst with activated carbon, and heat and fractionate in a rectification column to obtain polyether modified silicon oxide Alkane (I).

[0031] 70 parts of obtained polyether modified siloxane (I), 15 parts of silicon dioxide particles (U.S. Evonik company R106), 3.25 parts of sodium stearyl lactate, 0.5 part of sorbitol oleate, 11.25 parts of A 40% sodium ethylenediaminetetraacetic acid solution was stirred at room temperature for 30 minutes to obtain the product, which was designated as A-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com