Filling production line for defoaming by using ultrasonic wave

An ultrasonic and production line technology, applied in the fields of food, beverage and chemical industry, can solve the problems of small foam processing capacity, fog entrainment, environmental damage, etc., and achieve the effect of high defoaming efficiency, low power consumption and pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

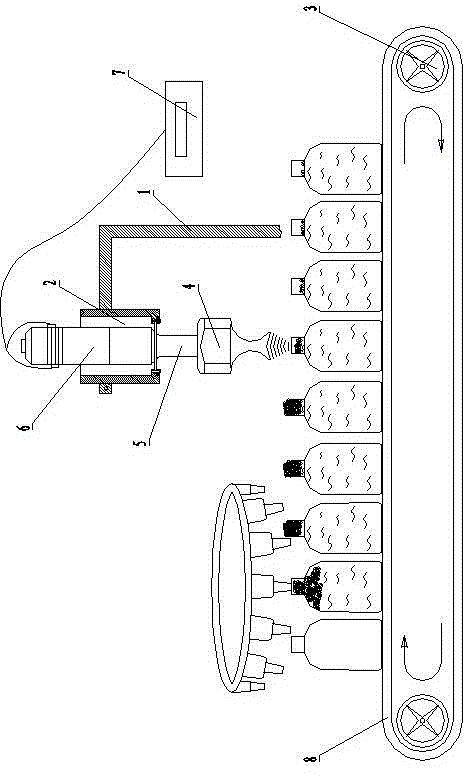

[0025] see figure 1 , the filling production line of ultrasonic defoaming of the present utility model, comprises ultrasonic generating device 2 and conveyor belt device 3, and described ultrasonic generating device 2 comprises tool head 4 and horn 5, ultrasonic transducer 6 and ultrasonic drive power supply in sequence 7. The conveyor belt device 3 includes a conveyor belt 8, the conveyor belt 8 is located below the ultrasonic generating device 2, the central axis of the tool head 3 is perpendicular to the central axis of the conveyor belt 8, and the bottom of the tool head 4 The end face is parallel to the surface of the conveyor belt 8, the liquid surface of the tank mouth on the conveyor belt is not in contact with the lower end surface of the tool head, and the upper surface of the conveyor belt 8 is provided with a water guide groove near the periphery, so that the overflowing air bubbles can be transported from the conveyor belt in time. No pollution to the conveyor bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com