Emulsion breaking type de-foaming agent for oil field and preparation method thereof

A defoamer and demulsification technology, applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve problems that have not been seen in the newspapers, and achieve a reduction in the dosage of chemicals, a simple preparation method, and high defoaming efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

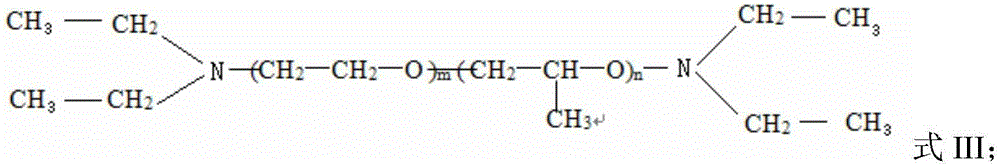

[0025] A kind of oil field demulsification type antifoaming agent is synthesized, by the polyether modified silicone oil that mass fraction is 10%, the polyethylene polyamine polyether that mass fraction is 5%, the synergist that mass fraction is 5%, mass fraction Prepared from 80% solvent, the synthesis steps are as follows:

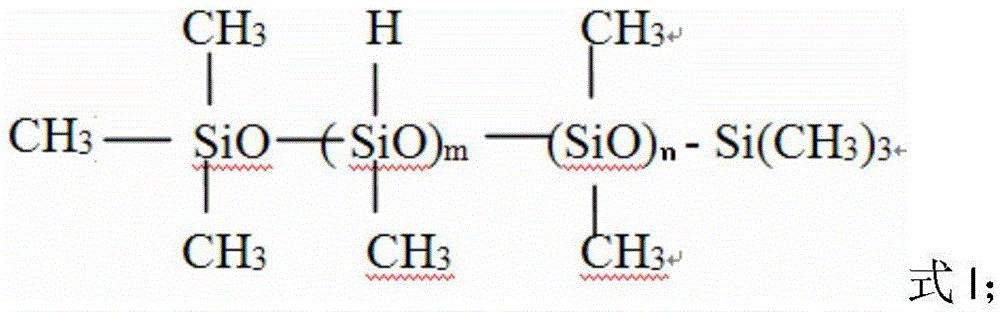

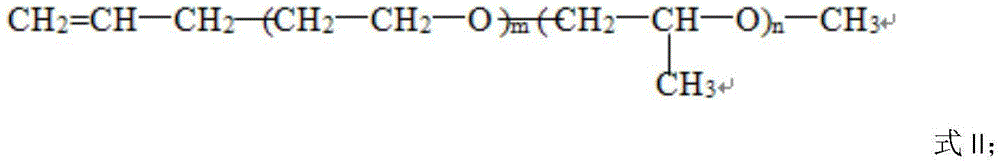

[0026] (1) First, 200g of hydrogen-containing polydimethylsiloxane compound (molecular weight: 1500g / mol, mass fraction of hydrogen content: 0.1%, calculated Si-H is 0.2mol), 105g polyether 1# (538g / mol mol, unsaturation 0.00186mol / g, calculated C=C is 0.195mol), 105g polyether 2# (molecular weight is 1000g / mol, unsaturated 0.001mol / g, calculated C=C is 0.105mol) into the reaction kettle , Bubble nitrogen for protection, stir and heat up to 80°C. Add 0.41g of 1% chloroplatinic acid-isopropanol solution, control the temperature at 90°C, and react at normal pressure for 2 hours to make polyether modified silicone oil; where polyether C=C: low hydrogen-co...

preparation example 2

[0029] A kind of synthesis of oil field demulsification type defoamer, by the polyether modified silicone oil that mass fraction is 7%, the polyethylene polyamine polyether that mass fraction is 4%, the synergist that mass fraction is 5%, mass fraction Prepared from 84% solvent, the synthesis steps are as follows:

[0030] (1) First, 200g of hydrogen-containing polydimethylsiloxane compound (molecular weight: 3500g / mol, mass fraction of hydrogen content: 0.3%, calculated Si‐H is 0.6mol), 200g polyether 1# (227g / mol mol, unsaturation 0.0044mol / g, calculated C=C is 0.88mol), 50g polyether 2# (molecular weight is 2000g / mol, unsaturation 0.0005mol / g, calculated C=C is 0.025mol) into the reaction kettle , Bubble nitrogen for protection, stir and heat up to 110°C. Add 0.23g of Pt-divinyltetramethyldisiloxane complex, control the temperature at 120°C, and react at normal pressure for 4 hours to make polyether modified silicone oil; where polyether C=C: low content The Si-H molar ra...

preparation example 3

[0033] A kind of oil field demulsification type defoamer is synthesized, by the polyether modified silicone oil that the mass fraction is 9%, the polyethylene polyamine polyether that the mass fraction is 2%, the synergist that the mass fraction is 1%, the mass fraction Prepared from 88% solvent, the synthesis steps are as follows:

[0034] (1) First, 200g of hydrogen-containing polydimethylsiloxane compound (molecular weight: 2000g / mol, hydrogen mass fraction: 0.28%, calculated Si-H is 0.56mol), 120g polyether 1# (molecular weight: 200g / mol, unsaturation 0.005mol / g, calculated C=C is 0.6mol), 80g polyether 2# (molecular weight is 1900g / mol, unsaturation 0.00053mol / g, calculated C=C is 0.04mol) added to the reaction The kettle was protected by blowing nitrogen gas, stirred and heated to 90°C. Add 0.2g of 1,3-divinyl-1,1,3,3-tetraphenyldisiloxane platinum, control the temperature at 120°C, and react at normal pressure for 3 hours to make polyether-modified silicone oil; The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com