Organic silicon defoamer for paper making industry and preparation method thereof

An organosilicon defoamer, a technology in the paper industry, applied in defoamers, papermaking, textiles and papermaking, etc., can solve the problem of loss of defoaming activity of silicone, limited effect of improving binding force, difficulty in controlling the amount of alkaline catalyst added, etc. low cost, good storage and dilution stability, and not easy to break the emulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

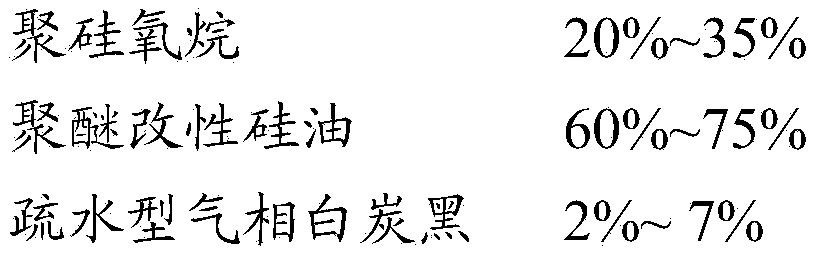

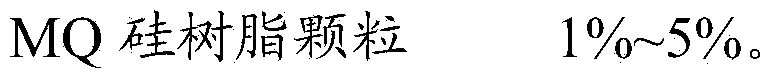

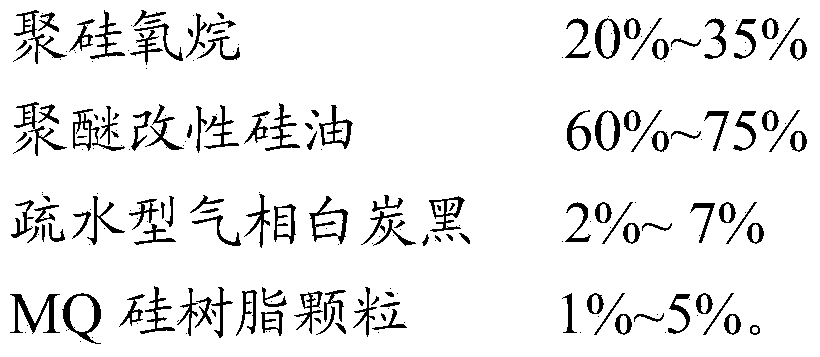

[0047] The preparation method of organosilicon defoamer for papermaking industry comprises the following steps:

[0048] Grinding MQ silicone resin with an M / Q value of 0.9 to a particle size of 5-20 μm to obtain MQ silicone resin particles;

[0049] Preparation of Emulsion A:

[0050] 300g of methyl silicone oil with a viscosity of 500000mPa·s at 25°C and 7g of a specific surface area of 238m 2 / g of hydrophobic fumed silica (manufactured by Guangzhou Jibisheng, HB-630), mixed with 25.5g of MQ silicone resin particles, stirred and mixed evenly at a low speed of 300rpm, heated to 230°C, and reacted at a high speed of 6000rpm for 2 Hours, until the mixed material is brown, close to brown, the reaction is considered complete, stop heating, stir and cool to below 80°C at a low speed of 300rpm, to obtain active composition A;

[0051] 7g sorbitan monostearate, 7.5g polyoxyethylene sorbitan monostearate and 1.5g ethylene glycol are mixed to obtain emulsifier, wherein sorbitan m...

Embodiment 2

[0058] The preparation method of organosilicon defoamer for papermaking industry comprises the following steps:

[0059] Grinding MQ silicone resin with an M / Q value of 0.4 to a particle size of 5-20 μm to obtain MQ silicone resin particles;

[0060] Preparation of Emulsion A:

[0061] 200g of hydroxyl silicone oil with a viscosity of 300000mPa·s at 25°C, 4g of a specific surface area of 150m 2 / g of hydrophobic fumed silica (manufactured by Guangzhou Jibisheng, HB-630) and 18.8g of MQ silicone resin particles were mixed, stirred and mixed evenly at a low speed of 250rpm, heated to 210°C, and reacted at a high speed of 5500rpm for 2 Hours, until the mixed material is brown, close to brown, the reaction is considered complete, stop heating, stir and cool to below 80°C at a low speed of 300rpm, to obtain active composition A;

[0062] Mix 8 g of sorbitan monooleate, 4 g of polyoxyethylene sorbitan monostearate and 5 g of fatty alcohol polyethylene glycol ether (Haian Petroch...

Embodiment 3

[0069] The preparation method of organosilicon defoamer for papermaking industry comprises the following steps:

[0070] Grinding MQ silicone resin with an M / Q value of 0.9 to a particle size of 5-20 μm to obtain MQ silicone resin particles;

[0071] Preparation of Emulsion A:

[0072] 200g of methyl silicone oil with a viscosity of 300000mPa·s at 25°C, 4.5g of a specific surface area of 260m 2 / g of hydrophobic fumed silica (manufactured by Degussa, AerosilR-812) and 33g of MQ silicone resin particles were mixed, stirred and mixed evenly at a low speed of 250rpm, heated to 250°C, and reacted for 2 hours under high-speed stirring of 5000rpm, Until the mixed material is brown, close to brown, the reaction is considered to be complete, stop heating, stir and cool at a low speed of 300rpm to below 80°C to obtain active composition A;

[0073] Mix 5.9g sorbitan monopalmitate, 3g polyoxyethylene sorbitan monooleate, 1.2g polyoxyethylene stearate (Haian Petrochemical, SG-6) with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com