Method for improving clarifying effect of molten glass in floating production and kiln device

A float glass and molten glass technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as poor clarification effect, trouble, and few glass substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

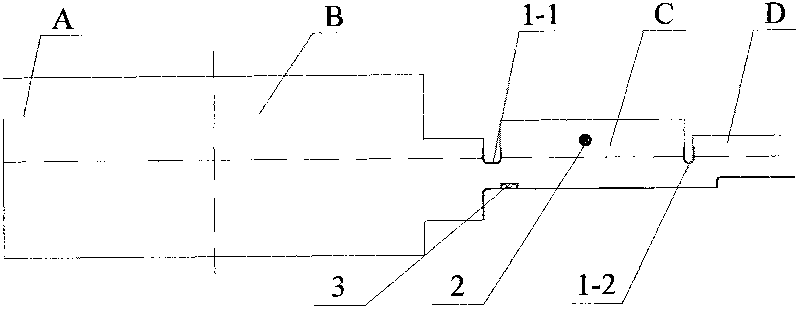

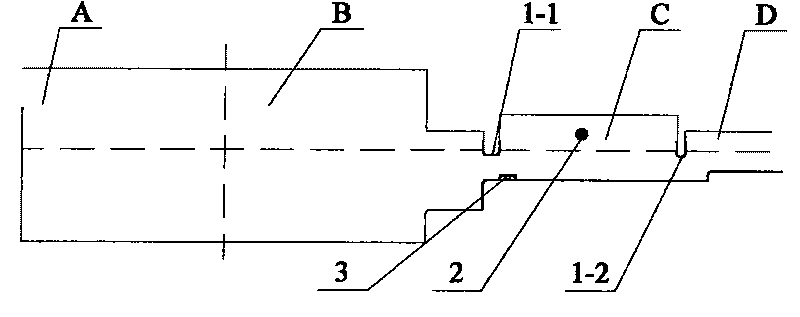

[0011] A method for improving the clarification effect of molten glass in float production. The above method is realized in a molten glass clarification furnace. For glass liquid output, a forced clarification area C is added between the clarification area B and the cooling adjustment area D of the clarification kiln to increase the length and residence time of the glass liquid clarification process. The molten glass is subjected to forced clarification.

[0012] A layer of platinum plating is provided on the bottom, side walls and refractory materials in contact with the molten glass in the forced clarification zone C in the clarification kiln.

[0013] Control the depth of molten glass in the forced clarification zone C at 250-350mm.

[0014] The electrodes of the above-mentioned electric heating device 3 are platinum electrodes, and the electric heating devices are divided into 5 groups, and the maximum power of each group is 200kw.

[0015] The above-mentioned decompress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com