Industrial waste gas dedusting, purifying and waste heat utilizing device

A technology for industrial waste gas and waste heat, which is applied in the direction of combined devices, climate change adaptation, and climate sustainability. It can solve the problems of poor purification effect, large volume, and high cost, and achieve improved work efficiency, improved dust removal effect, and increased discharge speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

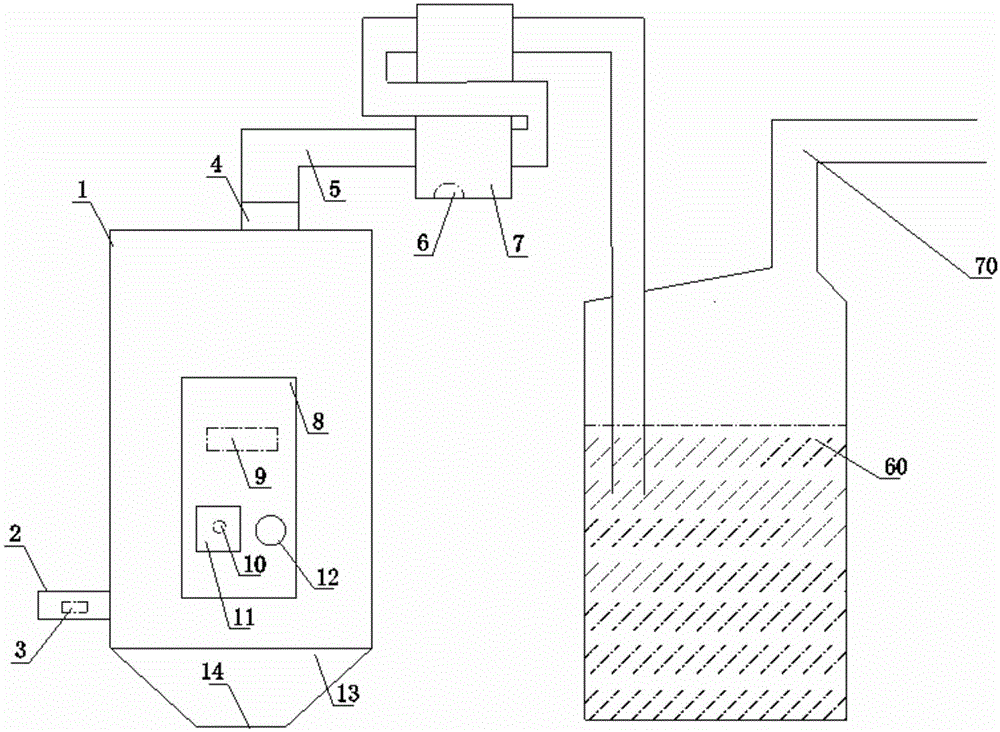

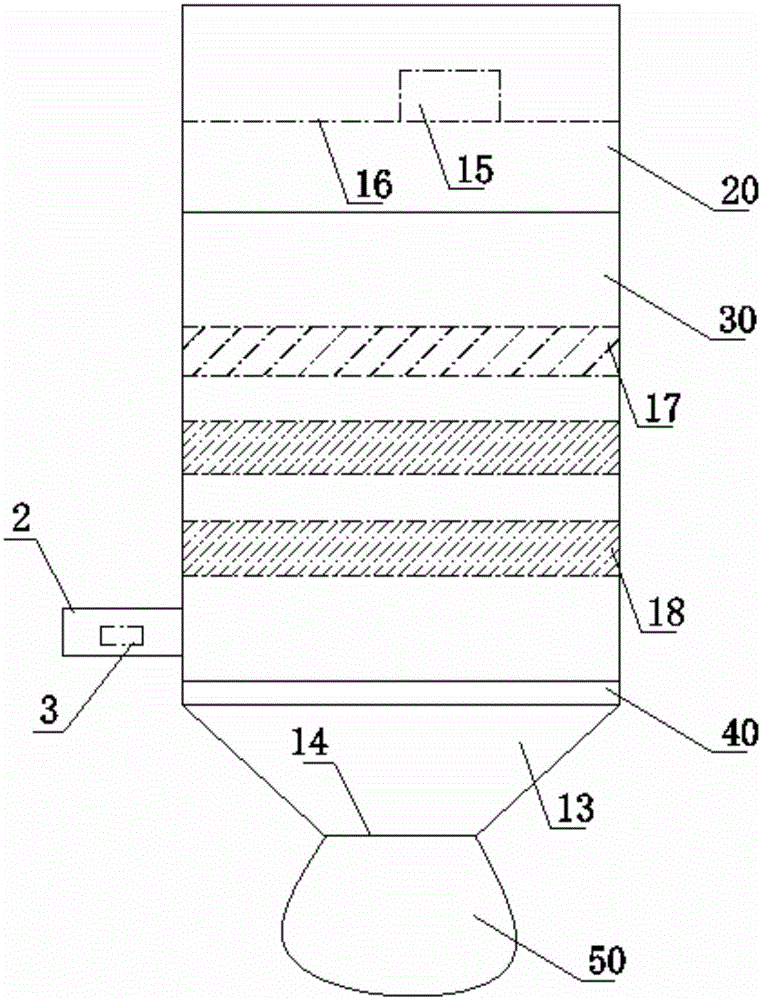

[0027] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

[0028] Such as figure 1 , figure 2 The device for dust removal and waste heat utilization of industrial waste gas includes a dust collector body 1, a flue gas inlet 2 is arranged at the bottom end of one side of the dust collector body 1, an air outlet 4 is arranged at the top of the dust collector body 1, and an air outlet 4 is arranged at the top of the dust collector body 1. 1. The blowing and suction chamber 20, the dust settling chamber 30 and the ash storage chamber 40 are arranged sequentially from top to bottom. A blowing device 15 and a hanging plate 16 are arranged in the blowing chamber 20 . A multi-layer filter layer 18 and an electrostatic precipitator layer 17 are arranged in the dust settling chamber 30 . An ash storage cavity 13 and a dust discharge port 14 are arranged in the ash storage chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com