Mechanical defoaming device applied to stirred tank reactor

A mechanical defoaming and stirring reactor technology, applied in chemical/physical/physical-chemical stationary reactors, foam dispersion/prevention, etc., can solve problems such as complex structure, achieve convenient loading and unloading, improve defoaming efficiency, and eliminate foam Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

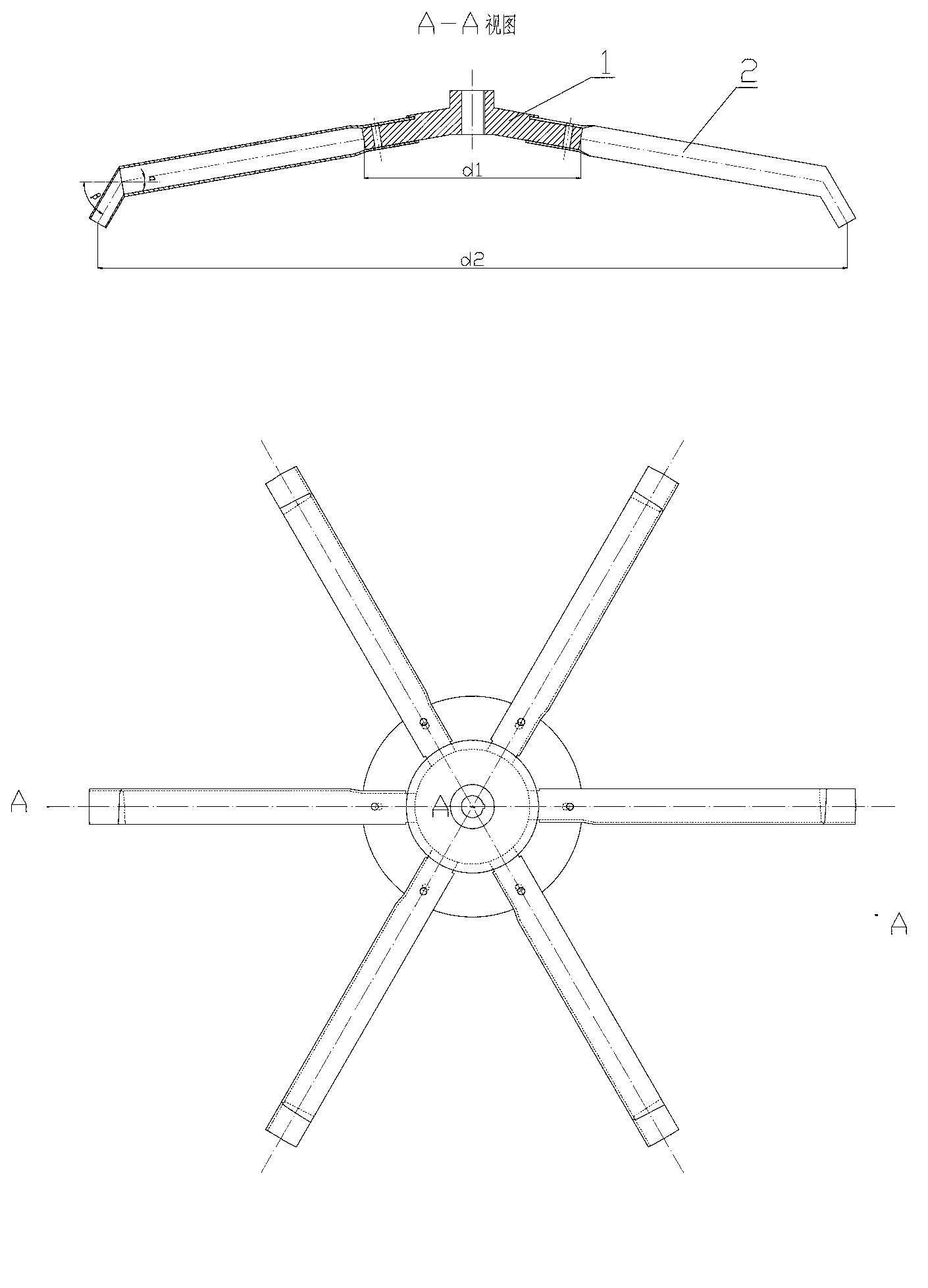

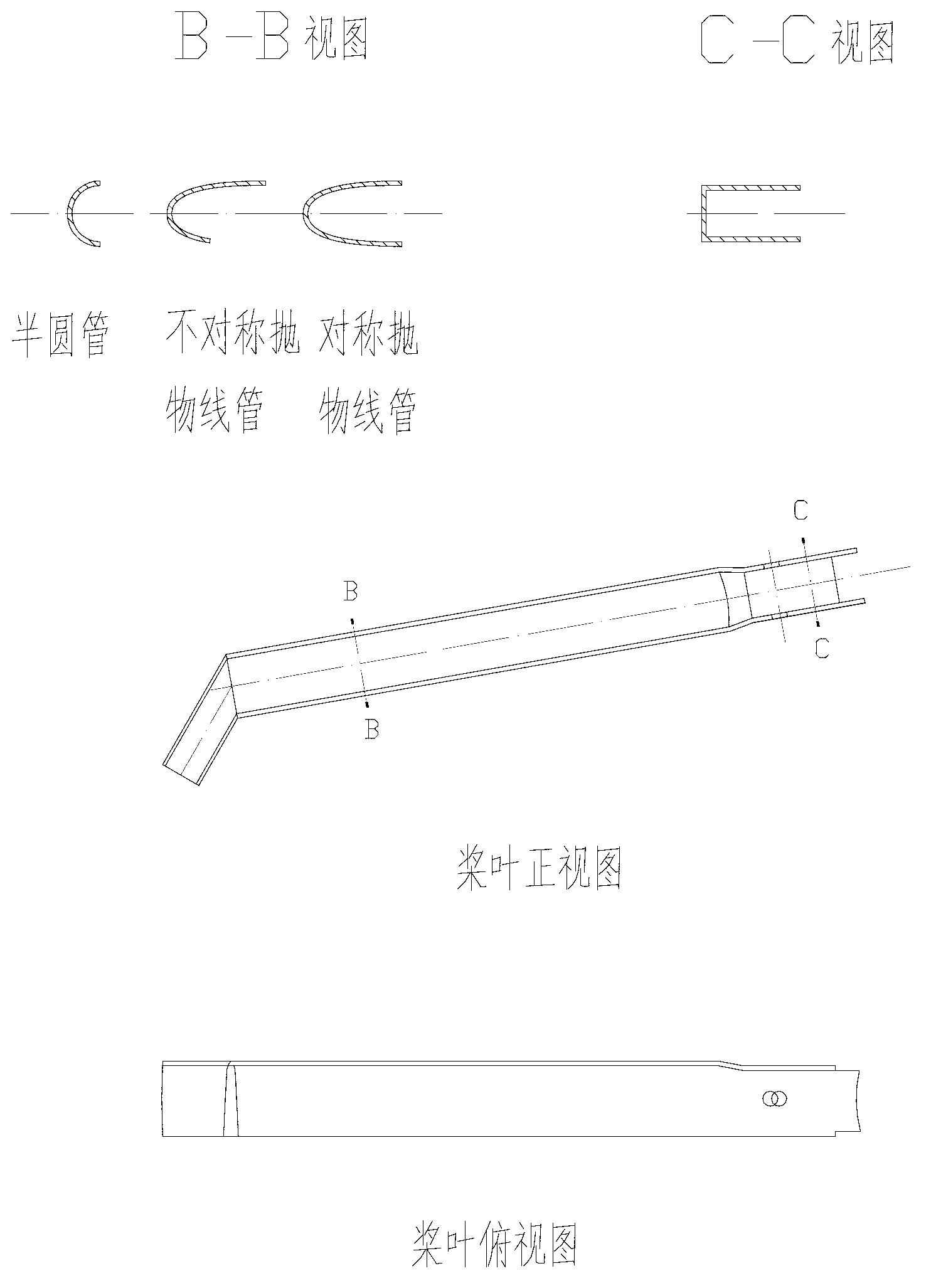

[0017] The mechanical defoaming device includes a hub 1 and paddles 2 . The central structure of the hub 1 is hollow cylindrical, the peripheral structure of the hub is truncated conical, the downward inclination angle α of the hub peripheral is 10o, and the diameter d1 of the hub is 1 / 5 of the kettle diameter. The section of the paddle 2 is an asymmetrical parabolic groove, and the paddle 2 is bent from an alloy thin plate. The diameter d2 of the paddle 2 is 3 / 5 of the diameter of the kettle, and the number of paddles is 6, which are arranged symmetrically on the hub. β is 60°. The mechanical defoaming device is installed on the stirring shaft in the stirred reactor and rotates together with the stirring shaft. The surfaces of the paddle 2 and the hub 1 are coated with a hydrophobic material, which is polytetrafluoroethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com