Preparation method of nano antimony tin oxide transparent insulation film

A nano-antimony tin oxide and transparent technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of difficult control of film particle size, high equipment requirements, and inability to form large-scale uniform films, etc., to achieve high visible light transmission High efficiency and infrared barrier, low cost, good market prospect and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

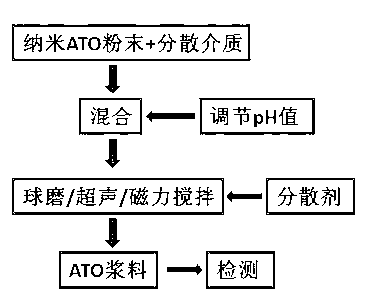

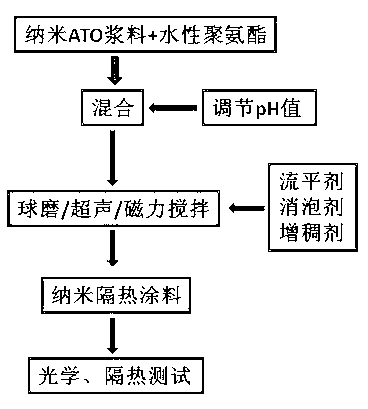

Method used

Image

Examples

Embodiment 1

[0020] Example 1, adding nano-ATO powder into the dispersant absolute ethanol, adjusting the pH value at 7-8 to be alkaline, fully dispersing and mixing, putting the mixture into a ball mill and milling for 20 h, and adding a stabilizer at the same time to obtain a well-dispersed Nano-ATO slurry system, in which the milling balls are agate beads with a diameter of 2-2.8 cm, and the rotation speed is 250 r / min. The nanometer ATO slurry that makes and aqueous polyurethane are V by volume ratio 纳米ATO浆料 :V 水性聚氨酯 = 1:4 mixing, control the pH value to 7~8, and then perform ball milling to disperse. During the dispersion process, add defoamer, leveling agent and thickener to water-based polyurethane according to 0.1wt%, 4wt% and 0.2wt% respectively In the preparation of nano-ATO thermal insulation coatings. Ordinary glass slides soaked in NaOH solution were ultrasonically cleaned in acetone, absolute ethanol and deionized water for 15 minutes respectively, and the coating film was...

Embodiment 2

[0021] Example 2, adding nano-ATO powder into the dispersant n-butanol, adjusting the pH value at 7-8 to be alkaline, fully dispersing and mixing, putting the mixture into an ultrasonic generator for ultrasonic dispersion for 40 min, and adding a stabilizer at the same time , to obtain a dispersed nano-ATO slurry system, wherein the ultrasonic generator frequency is 20000Hz. The nanometer ATO slurry that makes and aqueous polyurethane are V by volume ratio 纳米ATO浆料 :V 水性聚氨酯 = 1:6 mixing, control the pH value to 7~8, and then carry out ball mill dispersion. During the dispersion process, add defoamer, leveling agent, and thickener to water-based polyurethane according to 0.1wt%, 4wt%, and 0.2wt% respectively. In the preparation of nano-ATO thermal insulation coatings. Ordinary glass slides soaked in NaOH solution were ultrasonically cleaned in acetone, absolute ethanol and deionized water for 15 minutes respectively, and the coating film was pulled on the clean glass substrat...

Embodiment 3

[0022] Example 3, adding the nano-ATO powder into the dispersant n-butanol, adjusting the pH value to 7-8 to be alkaline, fully dispersing and mixing, putting the mixture into a ball mill for 24 hours, and adding a stabilizer at the same time to obtain a well-dispersed Nano-ATO slurry system, in which the milling balls are agate beads with a diameter of 2-2.8 cm, and the rotation speed is 250 r / min. The nanometer ATO slurry that makes and aqueous polyurethane are respectively by volume ratio V 纳米ATO浆料 :V 水性聚氨酯 = 1:1, 1:2, 1:3, 1:4, 1:6 mixing, control the pH value to 7~8, and then carry out ball milling to disperse. During the dispersing process, defoamer, leveling agent, thickener 0.1wt%, 4wt%, and 0.2wt% were added to water-based polyurethane in turn to prepare nano-ATO heat-insulating coatings. Ordinary glass slides soaked in NaOH solution were ultrasonically cleaned in acetone, absolute ethanol, and deionized water for 15 min, and coated on a clean glass substrate by wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com