Quick forming method of power type soft packaging polymer battery

A formation method and flexible packaging technology, which is applied in the field of rapid formation of power soft packaging polymer batteries, can solve the problems of SEI film impedance increase, pole piece deformation, and bubbles, so as to improve equipment utilization, shorten process and time, The effect of reducing the conversion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] A method for rapidly forming a power type soft-package polymer battery, comprising the following steps: 1) placing the battery flat in a jig, with the positive and negative tabs exposed; 2) adjusting the upper pressing plate of the jig so that it can press the battery, and Generate 3-5kgf / mm 2 Press the surface pressure of the battery against the surface of the battery, and adjust the limit screw to fix it; 3) Add the positive and negative connectors of the forming cabinet to the positive and negative tabs of the battery respectively; 4) Place the battery fixture in a high-temperature oven, set After the temperature is 60°C and the temperature is constant for 1 hour, the charging is carried out. The charging steps are: a) constant current charging 0.02C, time 10min; b) constant current constant voltage charging 0.1C-0.3C, charging current 0.3C, charging time 300min; When the charging current is 0.1C, the charging time is 900min, the limit voltage is 3.9V-4.0V, and the c...

Embodiment

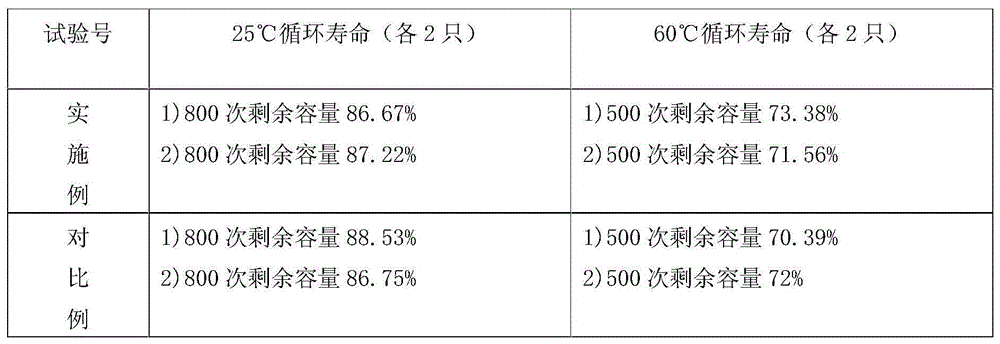

[0020] Embodiment: adopt the battery that the application method makes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com