QLED and preparing method thereof, and display device and preparing method thereof

A technology for display devices and functional layers, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., capable of solving problems such as unevenness of the quantum dot layer 40, deterioration of QLED performance, and corrosion of the hole transport layer 301

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

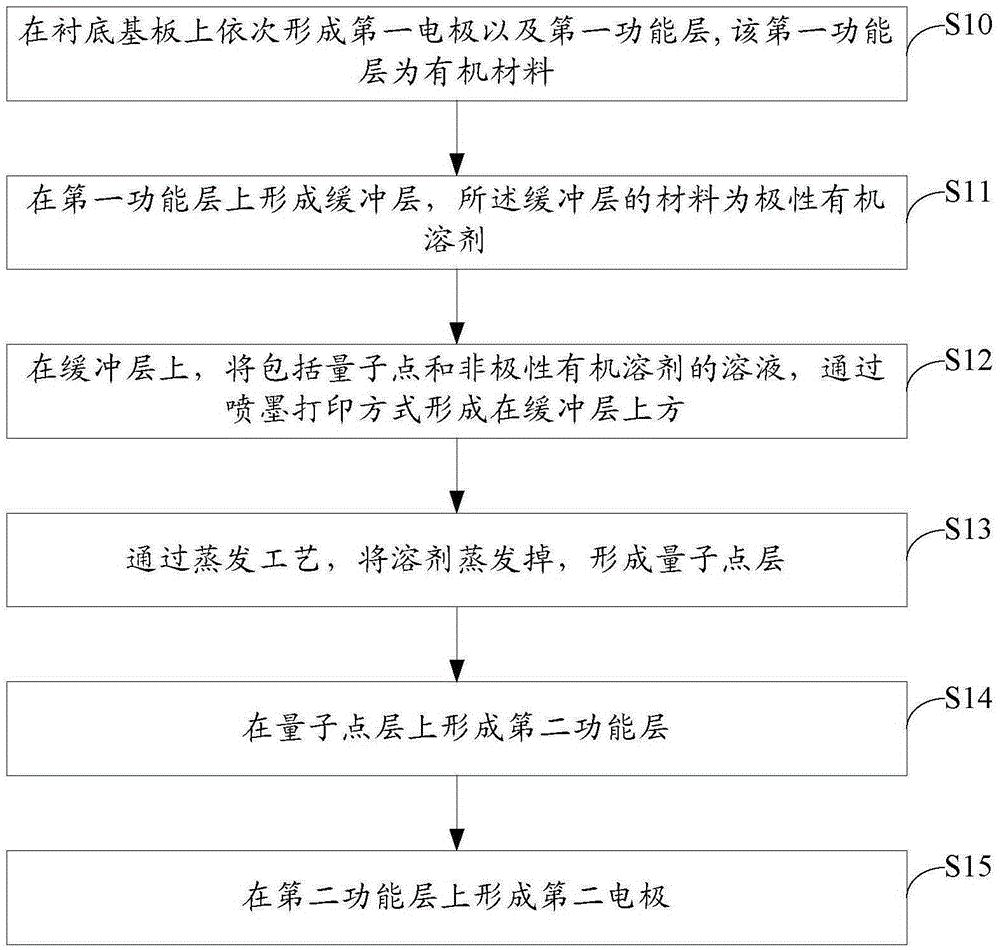

[0029] The embodiment of the present invention provides a preparation method of QLED, such as figure 2 Shown, this preparation method comprises the steps:

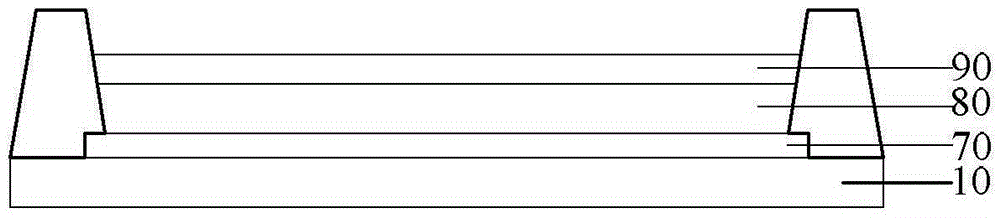

[0030] S10, such as image 3 As shown, a first electrode 70 and a first functional layer 80 are sequentially formed on the base substrate 10, and the first functional layer 80 is an organic material.

[0031] Here, the first functional layer 80 is not limited to one layer, and may be two or more layers.

[0032] S11, such as image 3 As shown, a buffer layer 90 is formed on the first functional layer 80, and the material of the buffer layer 90 is a polar organic solvent.

[0033] Here, the polar organic solvent is defined as a non-polar organic solvent capable of dissolving the following S12. A solution may be used to form the buffer layer 90 on the first functional layer 80 .

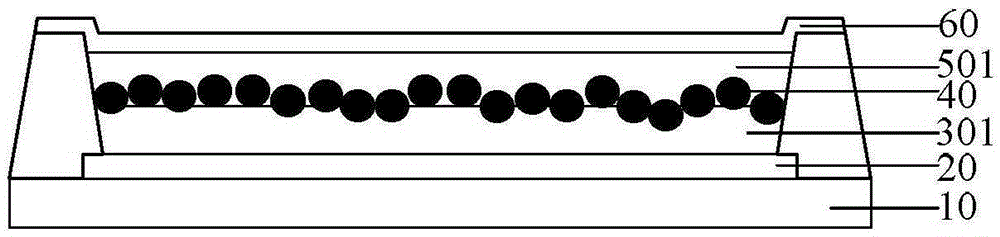

[0034] S12, such as Figure 4 As shown, on the buffer layer 90 , a solution 401 including quantum dots and a non-polar organic solvent is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com