Vertical falling-film heat exchanger outside pipe

A heat exchanger and falling film technology, applied in the field of new vertical falling film heat exchangers outside the tube, can solve the problems of low heat exchange effect and uneven film distribution, reduce mass transfer resistance, uniform liquid film, and ensure high efficiency The effect of heat and mass transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

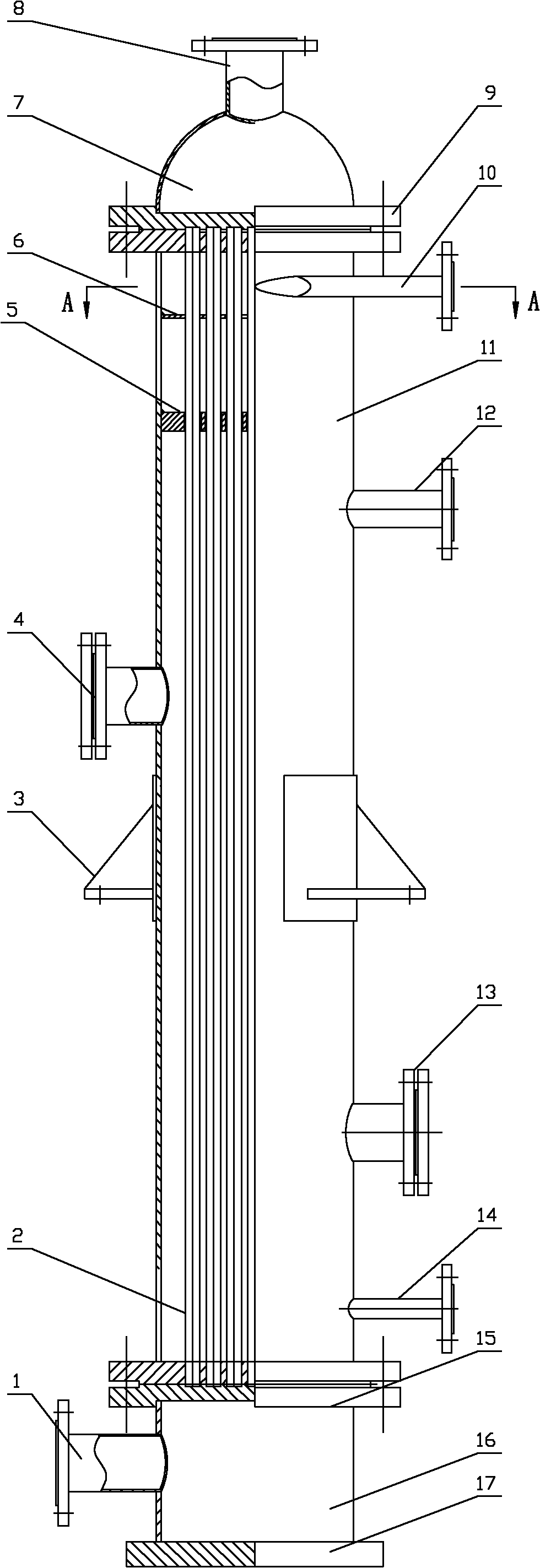

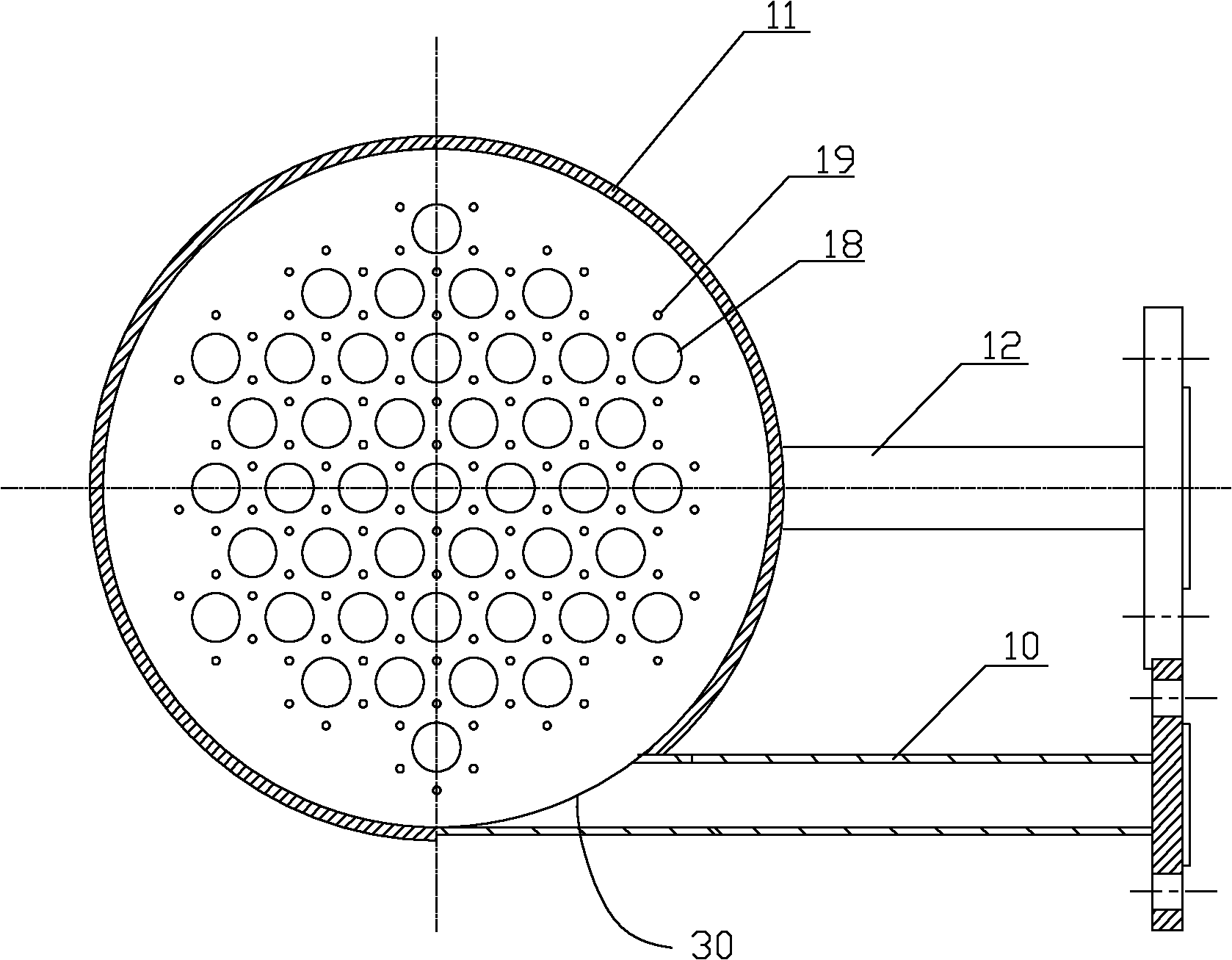

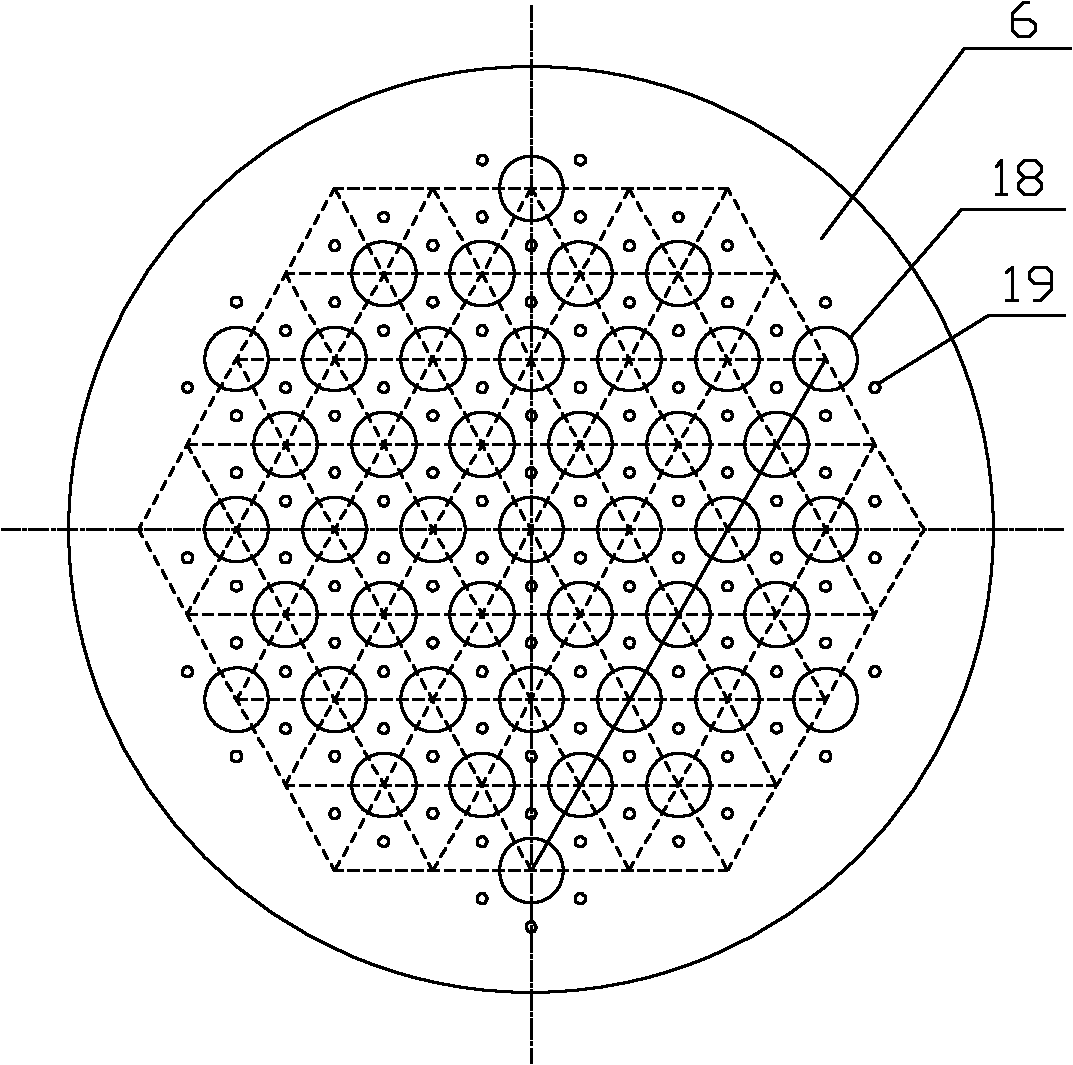

[0028] see figure 1 As shown, a vertical falling film heat exchanger outside the tube includes a heat exchanger shell 11, a support frame 3 is arranged outside the middle part of the heat exchanger shell 11, and a strengthening exchanging frame is vertically arranged inside the heat exchanger shell 11. The heat tube bundle 2, the bottom of the heat exchanger shell 11 is connected with the lower chamber 16 of the tube side through the flange 15, the bottom of the lower chamber 16 of the tube side is provided with a base 17, and the lower chamber 16 of the tube side is connected with the strengthening exchange The heat source / cold source inlet 1 connected by the heat pipe bundle 2 is connected with a solution outlet 14 on the lower side of the heat exchanger shell 11; The upper cavity 7 is provided with a heat source / cooler outlet 8 communicating with the enhanced heat exchange tube bundle 2, and the upper part of the heat exchanger shell 11 is provided with a solution inlet 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com