Polyethylene aluminum-plated film with metal luster of aluminum foil diffuse surface

A technology of aluminized film and metallic luster, which is applied in the field of polyethylene thin aluminized film, can solve the problems of poor adhesion of polypropylene film to aluminium, poor adhesion of aluminized polyethylene to aluminium, and easy peeling off of aluminium, achieving Increase decoration and anti-counterfeiting performance, increase surface appearance types, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

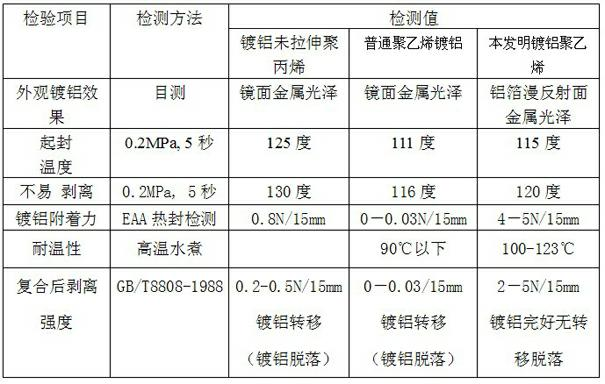

Image

Examples

Embodiment 1

[0020] Example 1 A polyethylene aluminum-coated single-layer film with metallic luster on the diffuse reflection surface of aluminum foil, the formula of the aluminum-coated functional layer in parts by mass is:

[0021] 50 parts of linear low density polyethylene, 50 parts of ethylene acrylic acid copolymer.

Embodiment 2

[0022] Example 2 A polyethylene aluminum-coated single-layer film with metallic luster on the diffuse reflection surface of aluminum foil, the formula of the aluminum-coated functional layer in parts by mass is:

[0023] 50 parts of linear low density polyethylene, 50 parts of ethylene methyl acrylate copolymer.

Embodiment 3

[0024] Example 3 A polyethylene aluminum-coated single-layer film with metallic luster on the diffuse reflection surface of aluminum foil, the formula of the aluminum-coated functional layer in parts by mass is:

[0025] 50 parts of linear low density polyethylene, 50 parts of ethylene vinyl acetate copolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com