Homogeneous epitaxial growth method of high-quality aluminum nitride film

A technology of homoepitaxial and growth methods, which is applied in the field of homoepitaxial growth of high-quality aluminum nitride films, which can solve the problems of large consumption of reagents, low lateral growth rate, polycrystalline growth of epitaxial layers, etc., and achieve material performance Good, low-cost growth, short growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

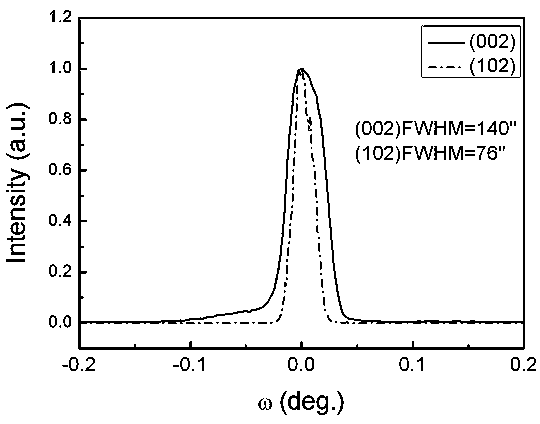

Examples

Embodiment 1

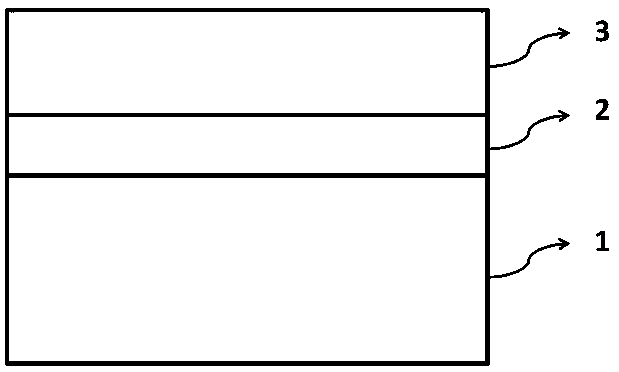

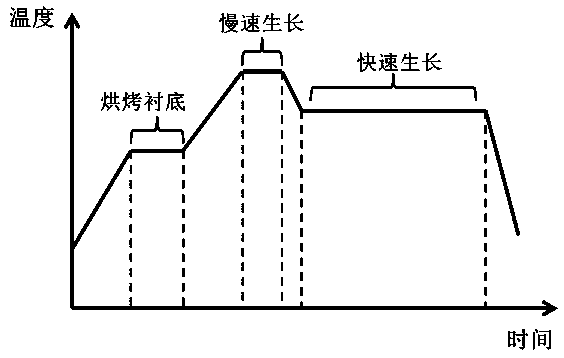

[0032] Such as figure 1 As shown, a homoepitaxial growth method of a high-quality aluminum nitride film comprises the following steps:

[0033] 1) Select a substrate 1, which is a (0001) plane single crystal aluminum nitride substrate material;

[0034] 2) Put the substrate into the MOCVD system and pass H 2 , the reaction chamber pressure is 200torr, heated at 1100°C for 10 minutes to clean the substrate surface, remove the surface oxide layer and contamination;

[0035] 3) The reaction chamber is protected with ammonia gas, and the temperature of the reaction chamber is raised to 1250 °C, H 2 As a carrier gas, the pressure of the reaction chamber is 50 torr, and trimethylaluminum is introduced at the same time, and the aluminum nitride optimization layer 2 is epitaxially grown at a V / III of 3000, with a growth rate of 300nm / h and a thickness of 100nm;

[0036] 4) Lower the temperature to 1150°C, H 2 As a carrier gas, reduce the pressure of the reaction chamber to 30torr,...

Embodiment 2

[0038] A method for homoepitaxial growth of a high-quality aluminum nitride film, characterized in that it comprises the steps of:

[0039] 1) Select a substrate 1, which is a (0001) plane single crystal aluminum nitride substrate material;

[0040] 2) Put the substrate into the MOCVD system and pass H 2 , the pressure of the reaction chamber is 100torr, heated at 1200°C for 3 minutes to clean the surface of the substrate and remove the surface oxide layer and contamination;

[0041] 3) The reaction chamber is vented with ammonia gas for protection, and the temperature of the reaction chamber is raised to 1350°C. 2 As a carrier gas, the pressure of the reaction chamber is 100 torrr, and trimethylaluminum is introduced at the same time, and the aluminum nitride optimization layer 2 is epitaxially grown with V / Ⅲ as 2000, the growth rate is 200nm / h, and the thickness is 20nm;

[0042] 4) Lower the temperature to 1250°C, H 2 As a carrier gas, reduce the pressure of the reaction...

Embodiment 3

[0044] A method for homoepitaxial growth of a high-quality aluminum nitride film, characterized in that it comprises the steps of:

[0045] 1) Select a substrate 1, which is a (0001) surface aluminum nitride-sapphire composite substrate;

[0046] 2) Put the substrate into the MOCVD system and pass H 2 , the pressure of the reaction chamber is 100torr, heated at 1200°C for 5 minutes to clean the surface of the substrate and remove the surface oxide layer and contamination;

[0047] 3) The reaction chamber is protected with ammonia gas, and the temperature of the reaction chamber is raised to 1250 °C, H 2 As a carrier gas, the pressure of the reaction chamber is 100 torrr, and trimethylaluminum is introduced at the same time, and the aluminum nitride optimization layer 2 is epitaxially grown at V / Ⅲ as 2000, the growth rate is 250nm / h, and the thickness is 50nm;

[0048] 4) Lower the temperature to 1200°C, H 2 As a carrier gas, reduce the pressure of the reaction chamber to 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com