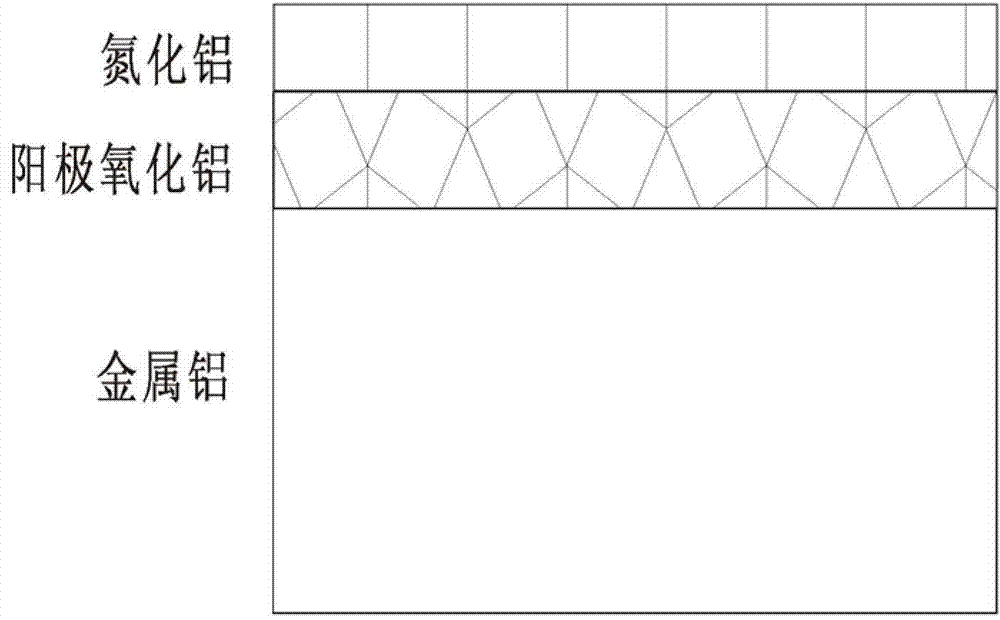

Metal aluminum base aluminum nitride package substrate and preparation method thereof

A technology based on aluminum nitride sealing and packaging substrates, which is applied in the field of microelectronic materials to achieve the effect of improving thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Use a tablet press to flatten the aluminum sheet with a thickness of 2mm under a pressure of 10MPa.

[0027] 2. Anneal at a temperature of 500°C for 3 hours to eliminate the internal stress of the aluminum sheet.

[0028] 3. Routine dewaxing, degreasing, pickling, alkali washing, deionized water cleaning.

[0029] 4. Electrochemical polishing: perform electrochemical polishing in the polishing solution of perchloric acid and absolute ethanol 1:4 for 2 minutes, and the current density is 10A / dm 2 .

[0030] 5. Anodic oxidation: The electrolyte is 0.3mol / L oxalic acid, and the anodic oxidation temperature and anodic oxidation voltage are adjusted by gradient:

[0031] The first level: temperature -30 ℃, voltage 200V, time 10 minutes;

[0032] Second stage: temperature -15°C, voltage 100V, time 10 minutes;

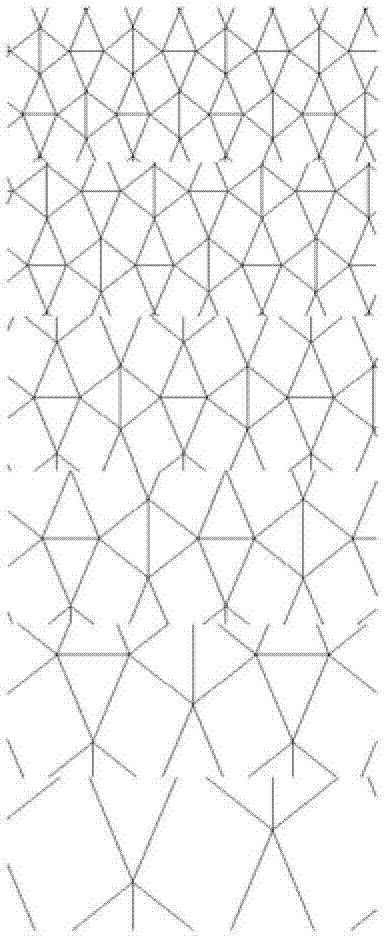

[0033] The third stage: the temperature is 4°C, the voltage is 40V, the time is 20 minutes, and the anodic oxidation is completed. The anodized aluminum film i...

Embodiment 2

[0038] 1. Use a tablet press to flatten the aluminum sheet with a thickness of 2mm under a pressure of 10MPa.

[0039] 2. Anneal at a temperature of 500°C for 3 hours to eliminate the internal stress of the aluminum sheet.

[0040] 3. Routine dewaxing, degreasing, pickling, alkali washing, deionized water cleaning.

[0041]4. Electrochemical polishing: perform electrochemical polishing in the polishing solution of perchloric acid and absolute ethanol 1:4 for 2 minutes, and the current density is 10A / dm 2 .

[0042] 5. Anodic oxidation: The electrolyte is 0.3mol / L oxalic acid, and the anodic oxidation temperature and anodic oxidation voltage are adjusted by gradient:

[0043] The first level: temperature -30 ℃, voltage 200V, time 30 minutes;

[0044] Second stage: temperature -15°C, voltage 100V, time 60 minutes;

[0045] The third stage: the temperature is 4°C, the voltage is 40V, the time is 120 minutes, and the anodic oxidation is completed. The anodized aluminum film i...

Embodiment 3

[0050] 1. Use a tablet press to flatten the aluminum sheet with a thickness of 2mm under a pressure of 10MPa.

[0051] 2. Anneal at a temperature of 500°C for 3 hours to eliminate the internal stress of the aluminum sheet.

[0052] 3. Routine dewaxing, degreasing, pickling, alkali washing, deionized water cleaning.

[0053] 4. Electrochemical polishing: perform electrochemical polishing in the polishing solution of perchloric acid and absolute ethanol 1:4 for 2 minutes, and the current density is 10A / dm 2 .

[0054] 5. Anodic oxidation: The electrolyte is 0.3mol / L oxalic acid, and the anodic oxidation temperature and anodic oxidation voltage are adjusted by gradient:

[0055] The first level: temperature -30 ℃, voltage 200V, time 10 minutes;

[0056] Second stage: temperature -15°C, voltage 100V, time 20 minutes;

[0057] The third stage: the temperature is 4°C, the voltage is 40V, the time is 40 minutes, and the anodic oxidation is completed. The anodized aluminum oxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com