Solar cell electrode, preparation method therefor, and solar cell

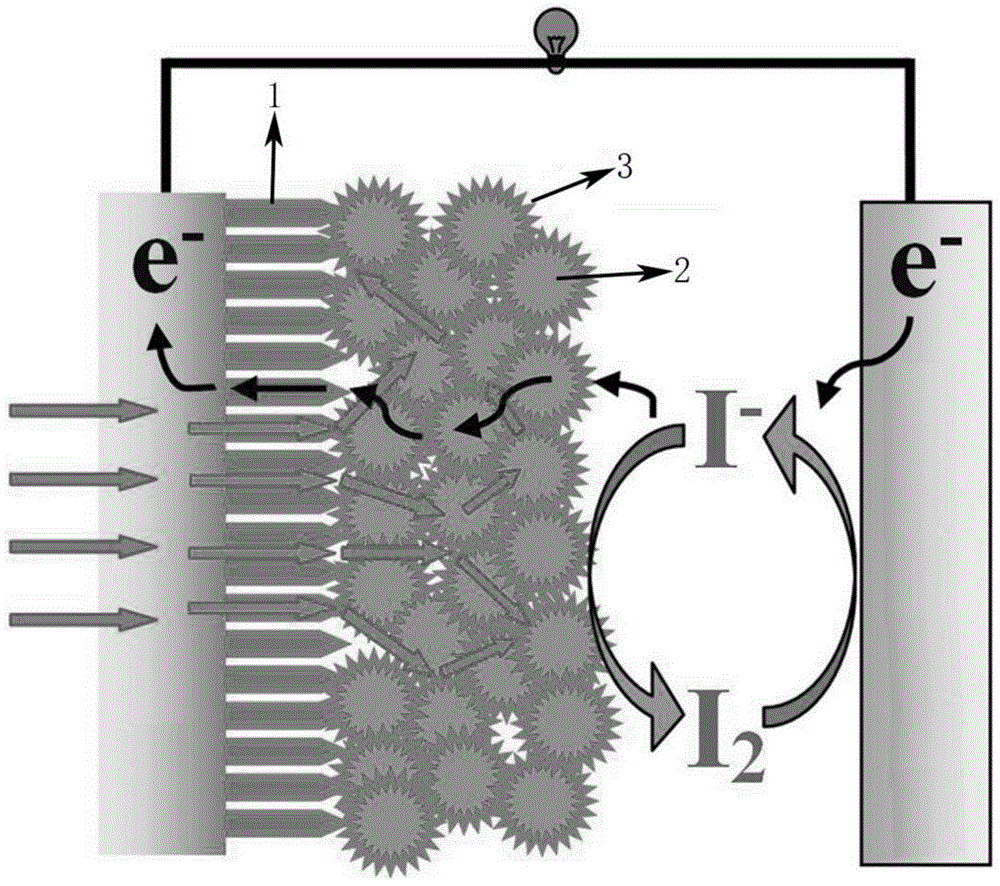

A solar cell and electrode technology, applied in electrolytic capacitors, circuits, capacitors, etc., can solve the problems that limit the development and application of high-performance solar cells, reduce the amount of dye adsorption, and make it difficult to scatter and absorb visible light with a large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

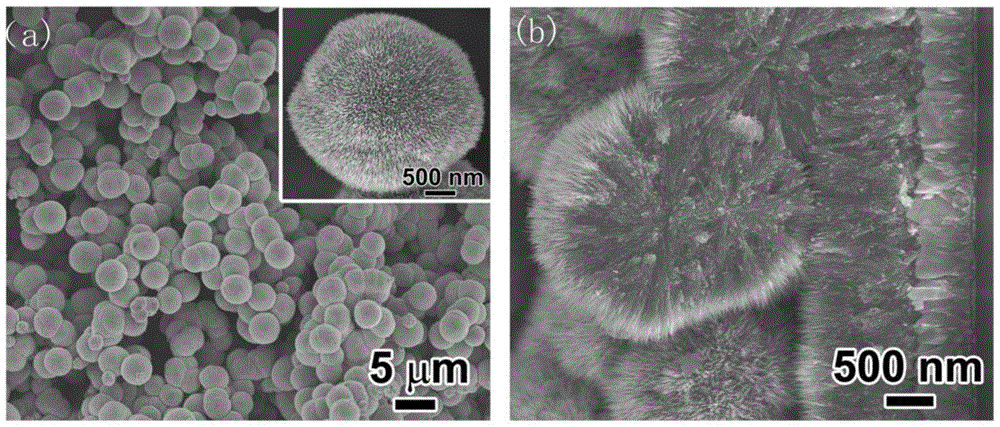

[0035] This embodiment provides a type I double-layer photoelectrode, the thickness of the one-dimensional nanowire array is 1 μm, the diameter of the one-dimensional nanowire is 10 nm, the diameter of the three-dimensional microsphere is 5 μm, and the thickness of the three-dimensional dendritic microsphere structure is 50 μm; Microstructural diagram such as figure 2 as shown, figure 2 (a) is a top view showing the size and stacking form of the upper three-dimensional dendritic nanospheres, figure 2 (b) Interface view, showing the combined morphology of 3D nanospheres and underlying 1D nanowires.

[0036] Follow the steps below to prepare solar cell electrodes:

[0037] (1) Prepare precursor solution: dissolve 1.4g tetraisopropyl titanate in 13.8g concentrated hydrochloric acid;

[0038]Surfactant solution: dissolve 0.25g of cetyltrimethylammonium bromide in 25g of deionized water;

[0039] Hydrolysis inhibitor solution: mix ethylene glycol and deionized water at a vol...

Embodiment 2

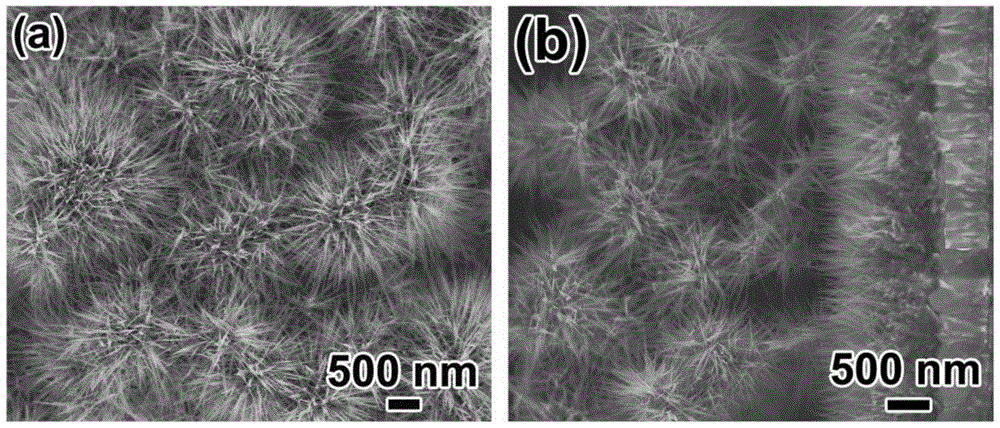

[0044] This embodiment provides a type II double-layer photoelectrode, the thickness of the one-dimensional nanowire array is 1 μm, the diameter of the one-dimensional nanowire is 6 nm, the diameter of the three-dimensional microsphere is 3 μm, and the thickness of the three-dimensional dendritic microsphere structure is 40 μm; Microstructural diagram such as image 3 as shown, image 3 (a) is a top view showing the size and stacking form of the upper three-dimensional dendritic nanospheres, image 3 (b) Interface view, showing the combined morphology of 3D nanospheres and underlying 1D nanowires.

[0045] Follow the steps below to prepare solar cell electrodes:

[0046] (1) Prepare precursor solution: dissolve 0.57g tetraisopropyl titanate in 13.8g concentrated hydrochloric acid;

[0047] Surfactant solution: 0.15g of cetyltrimethylammonium bromide was dissolved in 27.3g of deionized water;

[0048] Hydrolysis inhibitor solution: ethylene glycol pure solution;

[0049] M...

Embodiment 3

[0053] This embodiment provides a type III double-layer photoelectrode, the thickness of the one-dimensional nanowire array is 0.5 μm, the diameter of the one-dimensional nanowire is 4 nm, the diameter of the three-dimensional microsphere is 1.5 μm, and the thickness of the three-dimensional dendritic microsphere structure is 40 μm; Its microstructure is shown in Figure 4 as shown, Figure 4 (a) is a top view showing the size and stacking form of the upper three-dimensional dendritic nanospheres, Figure 4 (b) Interface view, showing the combined morphology of 3D nanospheres and underlying 1D nanowires.

[0054] Follow the steps below to prepare solar cell electrodes:

[0055] (1) Prepare precursor solution: dissolve 0.45g tetraisopropyl titanate in 13.8g concentrated hydrochloric acid;

[0056] Surfactant solution: 0.15g of cetyltrimethylammonium bromide was dissolved in 27.3g of deionized water;

[0057] Hydrolysis inhibitor solution: mix ethylene glycol and ethanol at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com