Coal bed underground gasifying method

An underground gasification and coal seam technology, applied in coal gasification, underground mining, construction, etc., can solve problems such as reducing operating pressure, and achieve the effect of increasing the generation rate and increasing the reaction contact surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

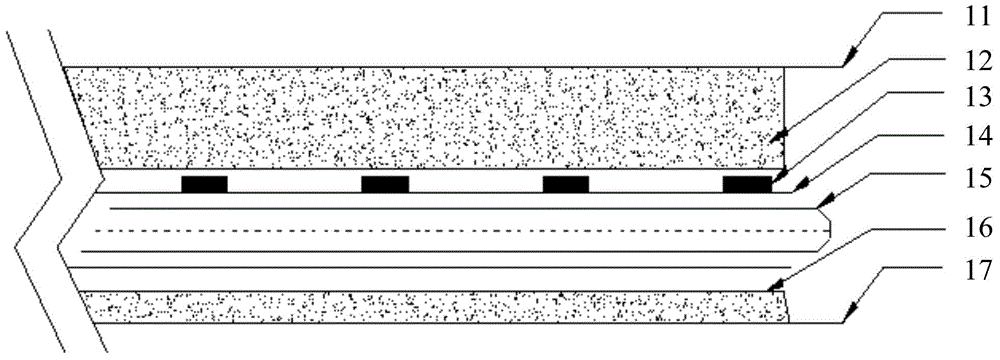

[0022] See figure 1 , which is a schematic diagram of the implementation of the directional drilling underground coal seam gasification in the first embodiment of the present invention. Such as figure 1 Shown:

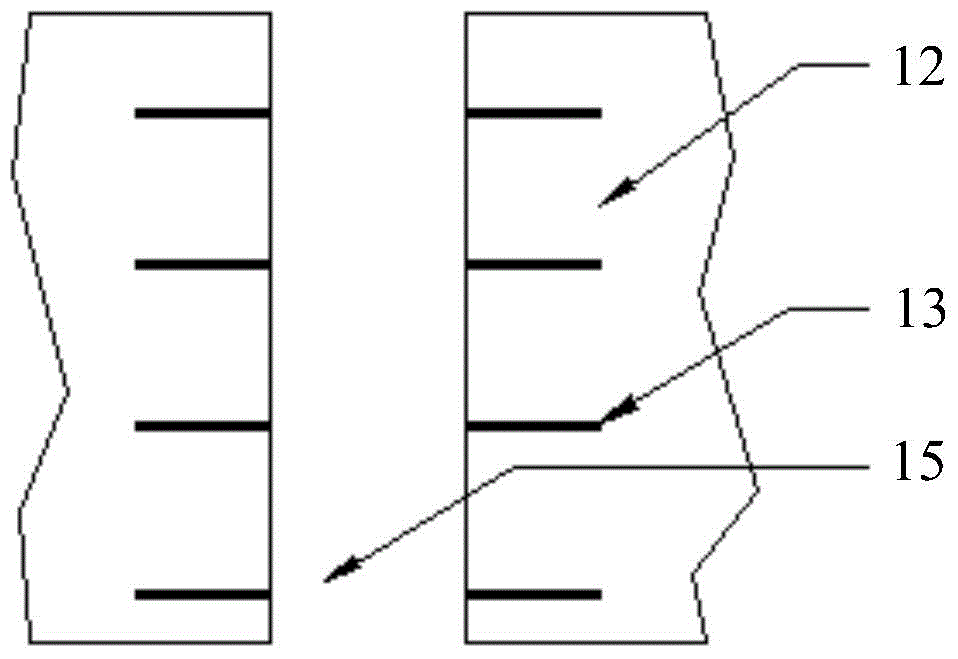

[0023] A plurality of explosive devices 13 independent of each other are arranged in the coal seam gasification channel 16 that has been constructed in the coal seam 12 to be gasified. The gasification channel 16 is formed between the coal seam top plate 11 and the coal seam bottom plate 17. In this embodiment, the gasification The channel 16 is directional drilling. According to the installation positions of multiple explosive devices 13, the coal seam 12 to be gasified is divided into multiple coal seam sections (not shown in the figure), and the multiple explosive devices 13 correspond to each coal seam section respectively. In addition, the explosion influence radius of each explosion device 13 is preferably the distance from the coal seam roof 11 , and the expl...

no. 2 example

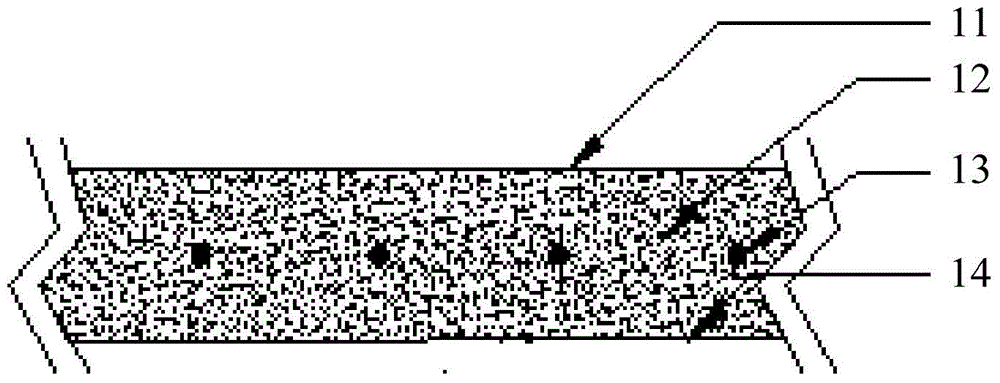

[0028] See Figure 2a and 2b , which is a schematic diagram of the way to realize underground gasification of tunnel-type well coal seams according to the second embodiment of the present invention. as shown in picture 2:

[0029] In tunnel-type well coal seam gasification, multiple explosive devices 13 are arranged in the coal seam 12 to be gasified, and each explosive device 13 is buried in the coal seam between the coal seam roof 11 and the coal seam floor 14 . The explosion influence radius of each explosion device 13 is preferably the distance from the coal seam roof 11 , and the explosion influence diameter is preferably the distance between each explosion device 13 . By increasing the thickness of the two ends of the buried explosive device 13, it will not be blasted when it explodes. After the explosion device 13 is arranged, the gap between it and the coal seam 12 to be gasified is sealed.

[0030] After that, it can be done like figure 1 As shown, a support pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com