Process for preparing benzoic ether plasticizer by using slurry method

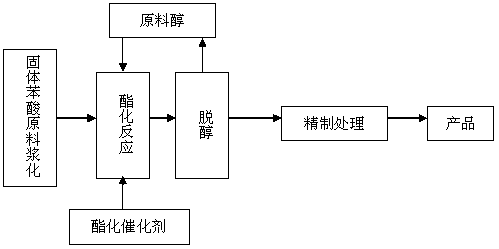

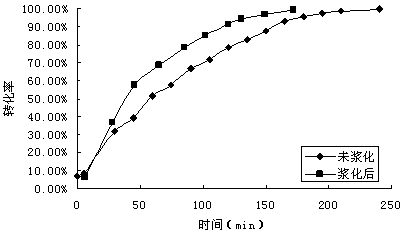

A technology for preparing benzoic acid esters and plasticizers, which is applied in the field of slurrying technology in the field of synthesizing benzoic acid plasticizers, can solve the problems of long time consuming and high energy consumption in the synthesis process, save energy consumption and improve reaction contact face, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Raw materials: terephthalic acid, isooctyl alcohol, catalyst;

[0021] 300g of terephthalic acid and 480g of isooctyl alcohol were added into a refiner and pulped for 50 minutes to make a mixed slurry. Take out 130g of slurry and add it to a three-necked bottle equipped with an oil-water separator, add 14g of isooctyl alcohol, add 0.2g of tetrabutyl titanate when the temperature is raised to 160°C, gradually stir and raise the temperature to 220°C, and keep the temperature for 2 hours until the acid value is lower than 1 to end the reaction. Then dealcoholized to get plasticizers.

Embodiment 2

[0023] Raw materials: terephthalic acid, isooctyl alcohol, catalyst;

[0024] 300g of terephthalic acid and 610g of isooctyl alcohol were added into a disc refiner and slurried for 60 minutes to prepare a mixed slurry. Take out 150g of slurry and add it to a three-necked flask equipped with an oil-water separator, raise the temperature to 160°C, add 0.2g of tetrabutyl titanate, gradually stir and raise the temperature to 220°C, keep the reaction for 1 hour until the acid value is lower than 1 to complete the reaction. Then dealcoholized to get plasticizers.

Embodiment 3

[0026] Raw materials: terephthalic acid, isooctyl alcohol, catalyst;

[0027] Add 300g of terephthalic acid and 565g of isooctyl alcohol into the colloid mill for slurrying for 60 minutes to make a mixed slurry. Take out 145g of slurry and add it to a three-necked flask equipped with an oil-water separator, raise the temperature to 160°C, add 0.4g of tetrabutyl titanate, gradually stir and raise the temperature to 230°C, keep the reaction for 2 hours until the acid value is lower than 1 to complete the reaction. Then dealcoholized to get plasticizers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com