Method for sulfur fixation temperature control burning of coal gangue and efficient coupling and utilizing of lime ash

A technology of coal gangue and ash slag is applied in the field of coal gangue solid sulfur solidification temperature-controlled combustion and efficient coupling utilization of ash and slag, which can solve the problems of frequent loader operations, inability to load materials in the system, and high system cost, and reduce investment, energy consumption and efficiency. The effect of maintenance cost, reduction of labor intensity, and improvement of working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

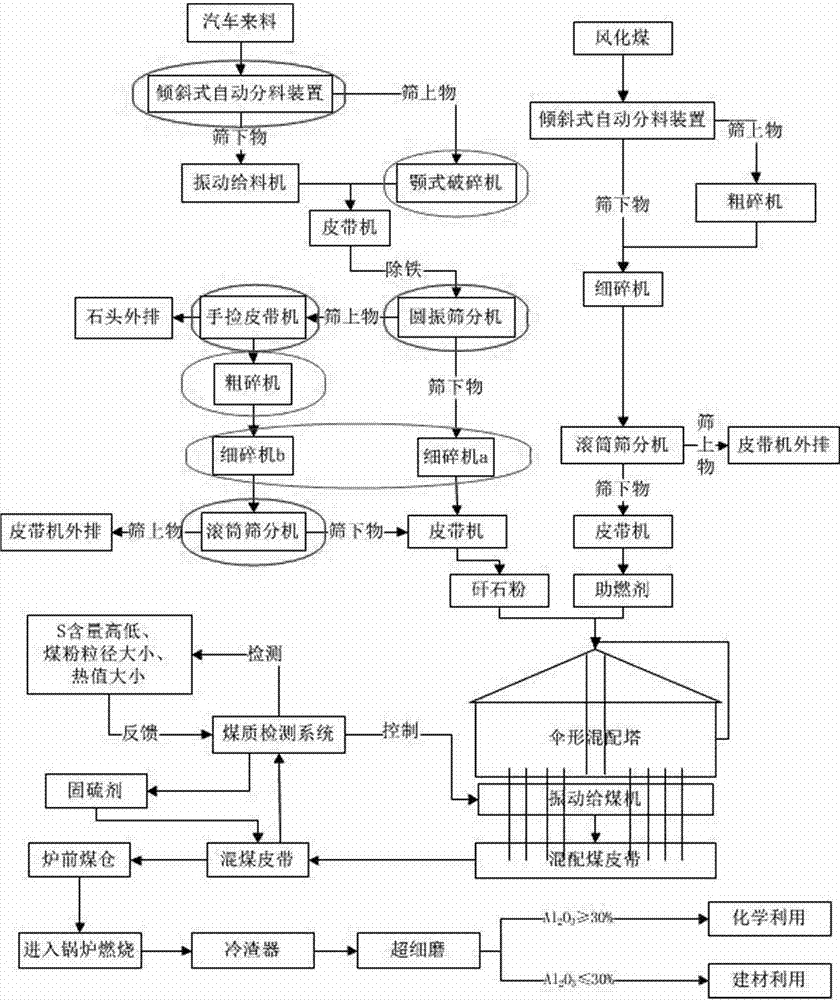

[0051] The following embodiments will further describe the present invention in conjunction with the accompanying drawings.

[0052] The following embodiment is a specific embodiment of the present invention, and does not limit the protection scope of the present invention.

[0053] Such as figure 1 As shown, there is an inclined automatic feeding device next to the coal yard, which includes: inclined mixed gangue automatic material distribution coal grate, 1 jaw crusher, 2 vibrating feeders, and 1 dust collector. Coarse crushing is carried out to ensure that the feeding particle size is ≤300mm, saving transportation and mixing energy.

[0054] Set up 1 low-quality fuel belt conveyor (processing capacity Q=700t / h, particle size 0-300mm), 1 set of iron remover (corresponding magnetic induction intensity ≥ 150mT), set 1 circular vibrating grading screen (screen hole 50mm, flow rate Q =700t / h, feeding particle size 0~300mm), 1 grading screen dust collector, 2 lump coal belt con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com