Cathode material for fast lithium ion conductor phase-modified lithium ion battery and preparation method thereof

A lithium-ion battery, lithium fast-ion technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor material cycle life, poor rate performance, rapid capacity decay, etc., to achieve high and low temperature performance compatibility, discharge ratio The effect of high capacity and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

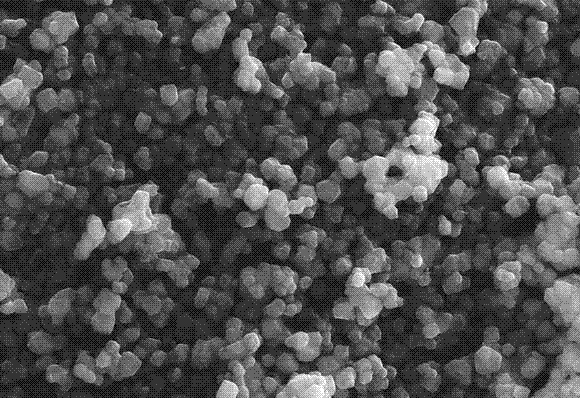

Image

Examples

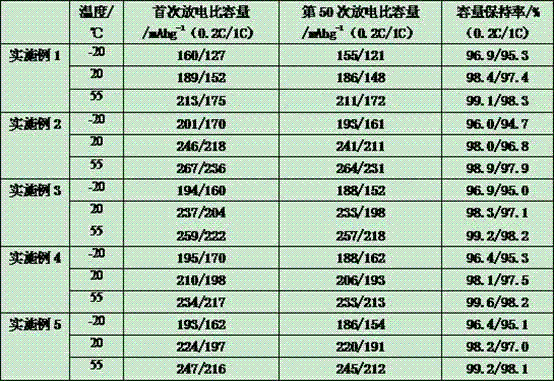

Embodiment 1

[0035] The composition of the rare earth element doped composite layered lithium ion battery positive electrode material modified according to the obtained lithium fast ion conductor phase is 0.98Li 2 MnO 3 ?0.02LiV 0.98 SM 0.01 Yb 0.01 o 2 0.1 La 0.57 Li 0.3 TiO 3 The stoichiometric ratio of the raw materials is weighed, and all the raw materials are added to the agate ball mill (agate ball) and mixed evenly, then a polyacrylamide (PAM) solution with a mass concentration of 10% is added, wherein the molecular weight of PAM is 6 million, polypropylene The mass of the amide solution accounts for 15% of the total mass of the raw materials. Add water and ball mill for 0.5 hours to obtain a paste slurry; after being fully dried in an air atmosphere at a temperature of 80°C, pulverize it, and then program the temperature to 950°C in an air atmosphere , keep warm for 5 hours, and after cooling down with the furnace, the target product lithium fast ion conductor phase-modified...

Embodiment 2

[0037] According to the composition of the positive electrode material of the rare earth element doped composite layered lithium ion battery is 0.1Li 2 TiO 3 ?0.9LiMn 0.6 Fe 0.29 co 0.1 Nd 0.01 o 2 The stoichiometric ratio and lithium fast ion conductor composition is La 0.475 Li 0.475 Sr 0.05 TiO 3 Weigh the raw materials separately, then add the raw materials into the polyurethane ball mill tank (zirconia ball) and mix evenly, then add the polyacrylamide (PAM) solution with a mass concentration of 10%, wherein the molecular weight of PAM is 2 million , the quality of the polyacrylamide solution accounts for 20% of the total mass of the raw materials, add water and ball mill for 4 hours to obtain a paste slurry; after the air atmosphere is fully dried at a temperature of 150 ° C, it is pulverized, and the temperature is programmed to rise to 900 ° C under an air atmosphere , heat preservation for 8 hours, after cooling down with the furnace, the required rare earth e...

Embodiment 3

[0039] According to the rare earth element doping composite layered lithium ion battery positive electrode material 0.4Li 2 MnO 3 ?0.6LiNi 0.5 Cr 0.3 La 0.1 Ce 0.1 o 2 The stoichiometric ratio of the raw materials is weighed, and the raw materials are added to a stainless steel ball mill (stainless steel ball) and mixed evenly, and then a polyacrylamide (PAM) solution with a mass concentration of 10% is added. Among them, the molecular weight of PAM is 20 million, and polyacrylamide The quality of the solution accounts for 2% of the total mass of the raw materials weighed, and after adding water and ball milling for 6 hours, a paste slurry is obtained; after being fully dried under an air atmosphere at a temperature of 100 ° C, it is pulverized, and the temperature is programmed to rise to 800 ° C under an oxygen-enriched atmosphere. After heat preservation for 10 h and quenching, the required rare earth element doped composite layered lithium ion battery positive electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com