Porous carbon material used for lithium-air cell anode

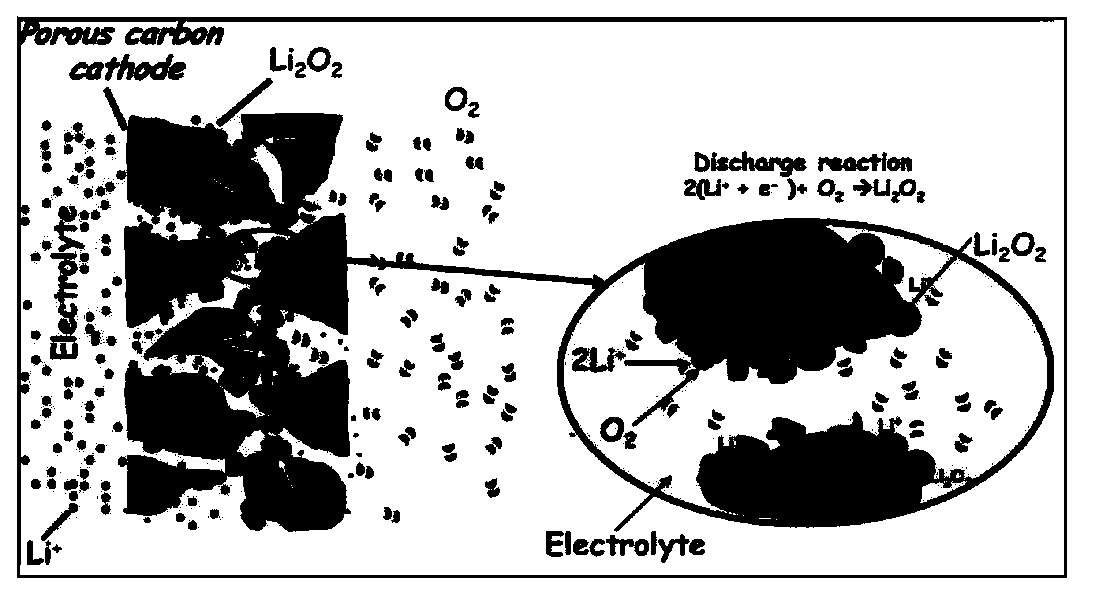

A porous carbon material, air battery technology, applied in battery electrodes, fuel cell type half cells and secondary battery type half cells, circuits, etc. Utilize the problems of space and the limited stacking thickness of discharge products to achieve the effect of improving space utilization, improving energy density and power density, and shortening diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Porous carbon materials with hierarchical pore structure were prepared using nano-magnesium carbonate powder as a template. Accurately weigh 5g of glucose, add 15ml of water and stir until completely dissolved, then add 3g of citric acid and 5g of magnesium carbonate, heat and mechanically stir in a water bath at 80°C to make it completely dispersed, and dry at 80°C after the water is completely evaporated 24h. Then put the dried product into a high-temperature tube furnace for carbonization, the atmosphere is nitrogen, and the gas flow is controlled at 30ml / min. After carbonization at 800°C for 2 hours, the nanoparticle / carbon composite was obtained, and an appropriate amount of 2M dilute hydrochloric acid was added to remove nano-magnesium carbonate. After filtration, it was vacuum-dried at 80°C for 24 hours, and a porous carbon material with a hierarchical pore structure was obtained.

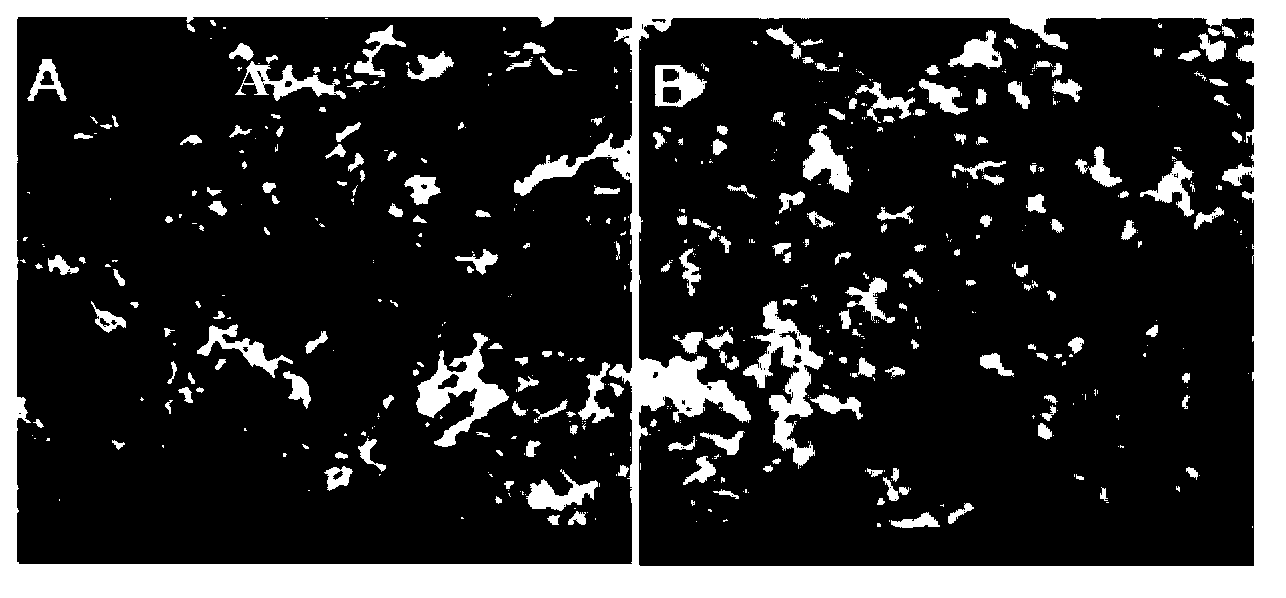

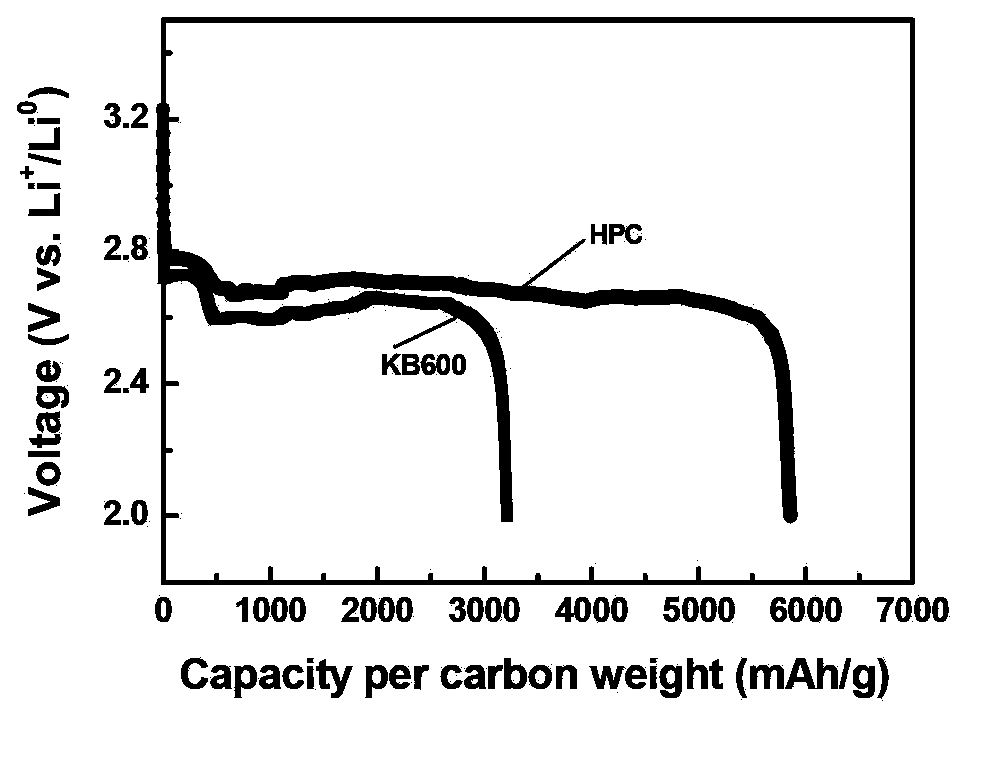

[0045] The positive electrode material structure prepared in Example 1 has a lar...

Embodiment 2

[0050] SiO 2 The sol is used as a template to prepare porous carbon materials with hierarchical pore structure. Accurately weigh 5g of glucose, 0.2716g of cobalt nitrate hexahydrate, add 15ml of water and stir until completely dissolved, then add 5g of SiO 2 The sol was mechanically stirred to completely disperse it, heated and mechanically stirred in a water bath at 80°C, and dried under vacuum at 80°C for 24 hours after the water was completely evaporated. Then put the dried product into a high-temperature tube furnace for carbonization, the atmosphere is nitrogen, and the gas flow is controlled at 30ml / min. Nano-SiO was obtained by carbonization at 900°C for 3 hours 2 / carbon composite, plus an appropriate amount of 1M HF to remove SiO 2 And the generated cobalt oxide is filtered and then vacuum-dried at 80°C for 24 hours to obtain a porous carbon material with a hierarchical pore structure.

Embodiment 3

[0052] Porous carbon materials with hierarchical pore structure were prepared using nano-calcium carbonate powder as a template. Accurately weigh 5g of glucose and 2g of nickel hydroxide, add 10ml of water and stir until completely dispersed, then add 3g of calcium carbonate, heat and mechanically stir in a water bath at 80°C to make it completely dispersed, and put it in a vacuum at 80°C after the water is completely evaporated Dry for 24h. Then put the dried product into a high-temperature tube furnace for carbonization, the atmosphere is nitrogen, and the gas flow is controlled at 20ml / min. After carbonization at 900°C for 2 hours, the nanoparticle / carbon composite was obtained, and then the nano-calcium carbonate and nickel oxide were removed with an appropriate amount of 2M dilute hydrochloric acid. After filtration, it was vacuum-dried at 80°C for 24 hours to obtain a porous carbon material with a hierarchical pore structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com