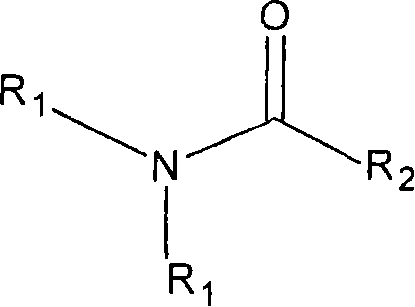

Elution-extracting resin using amide compound as extracting agent and preparation method thereof

A technology for amide compounds and diamide compounds, applied in chemical instruments and methods, separation methods, liquid separation of solid adsorbents, etc., can solve the problems of poor repeatability and reproducibility, short service life, and large loss of extractant. , to achieve the effect of good extraction capacity, easy operation and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

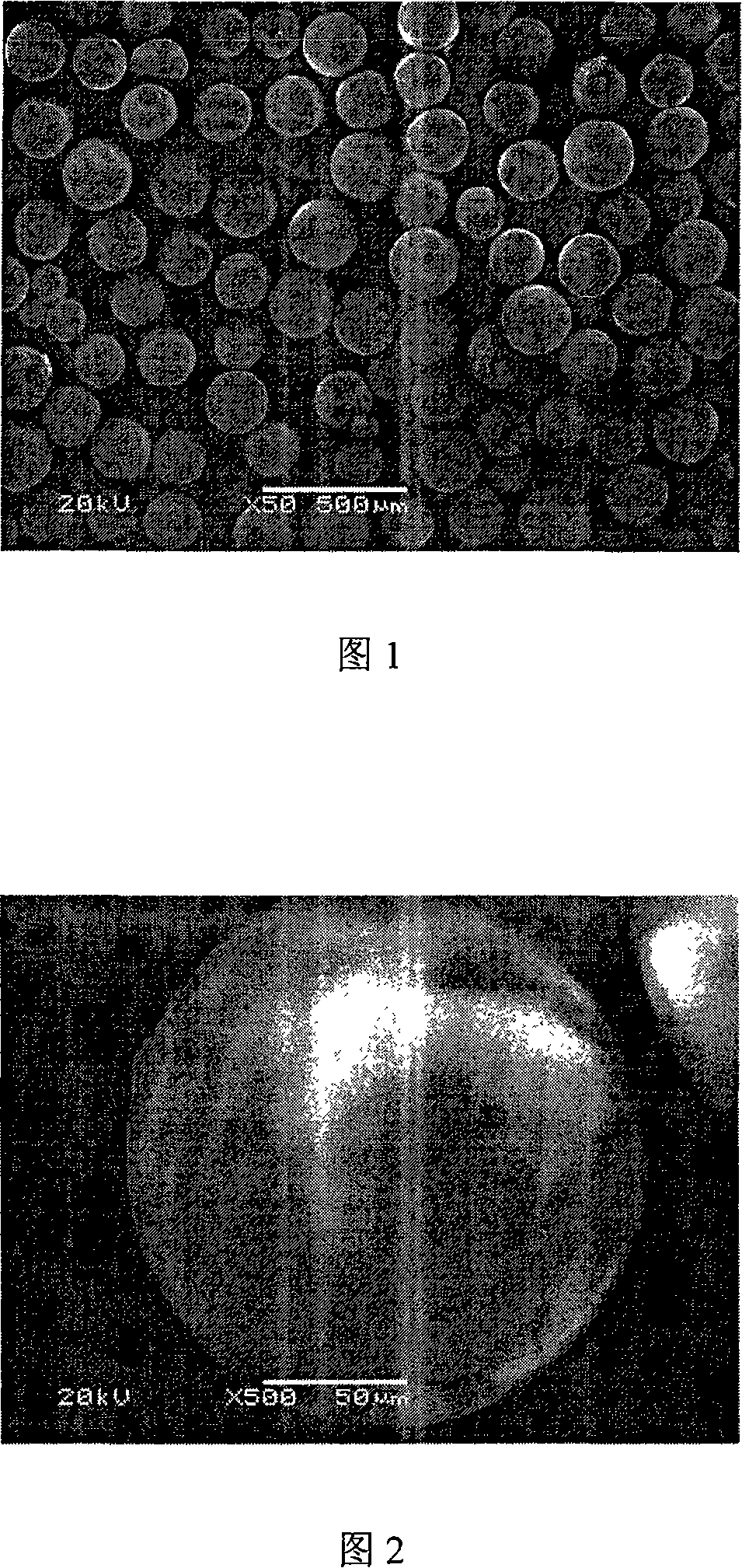

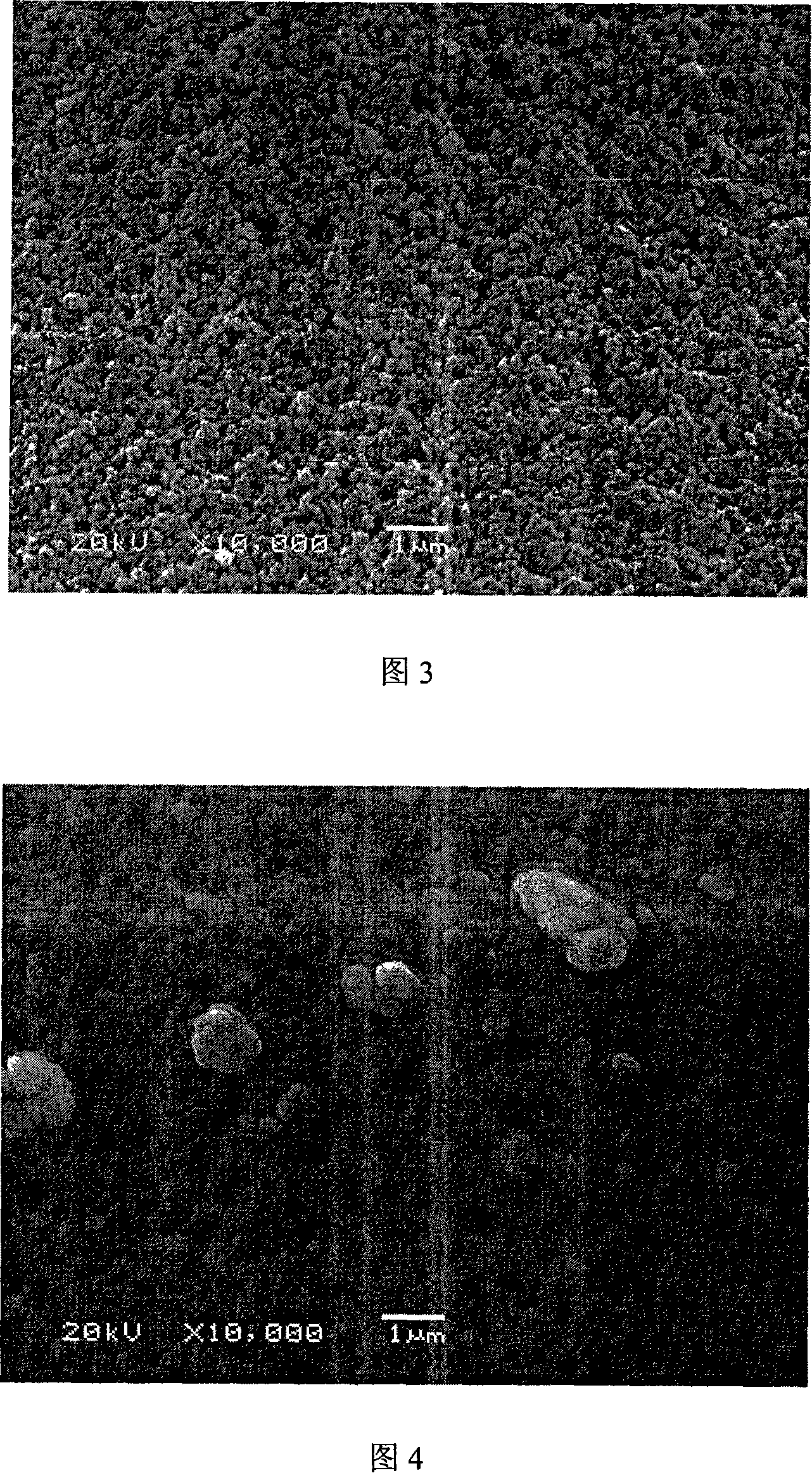

[0054] In a reaction vessel equipped with a mechanical stirrer and a condenser tube, first mix 8 parts of monomer styrene and 2 parts of crosslinking agent divinylbenzene evenly, then add benzoyl peroxide with a monomer amount of 1%, 4 parts N, N-dihexyl-heptanamide, 3 parts of kerosene and 2 parts of n-octanol, 2 parts of toluene and 5 parts of n-heptane, at room temperature, stir to form an oil phase; 10% gelatin, 2% calcium carbonate and 3% sodium dodecylbenzenesulfonate are added to deionized water that is 3 times the volume of the oil phase, dispersed while maintaining a stirring speed of 800r / min, and heated up React at 80°C for 10 hours, then cool down, wash with hot water at 50°C to remove unreacted monomers, dispersants and surfactants until the water is clear, then filter with suction, and dry at low temperature at 70°C to obtain white leaching resin particles. The particle size of the particles is 100-200 mesh.

Embodiment 2

[0056] In a reaction vessel equipped with a mechanical stirrer and a condenser, first mix 7 parts of monomer styrene and 3 parts of crosslinking agent divinylbenzene, and then add benzoyl peroxide with a monomer amount of 0.5%, 10 parts N, N, N', N'-tetraisobutyl diglycolamine, 1 part of kerosene, 2 parts of n-octane, 3 parts of toluene and 3 parts of n-heptane, stirred evenly at room temperature to form an oil phase; Will be 10% methylcellulose by oil phase weight, 10% calcium phosphate and 2% sodium lauryl sulfonate, join with the deionized water of oil phase volume 2 times, keep stirring speed Disperse under the condition of 500r / min, and heat up to 70°C for 16h reaction, then cool, wash after cooling, and filter with suction. The drying conditions are the same as in Example 1, omitting. The particle size of the particles is 80-200 mesh.

Embodiment 3

[0058] In a reaction vessel equipped with a mechanical stirrer and a condenser, first mix 7 parts of monomer styrene and 3 parts of crosslinking agent divinylbenzene, and then add azobisisobutyronitrile with a monomer amount of 1.5%, 10 Parts of N, N, N', N'-tetrabutyl diglycolamine, 1.5 parts of n-octane and 1.5 parts of chloroform, 10 parts of n-heptane, at room temperature, stir evenly to form an oil phase; 10% polyacrylic acid by weight, 20% magnesium carbonate and 5% sodium lauryl sulfate are added to deionized water with 5 times the volume of the oil phase, and dispersed under the condition of maintaining a stirring speed of 500r / min. The temperature was raised to 90° C. for 10 hours, and then cooled. After cooling, the mixture was washed and filtered with suction. The drying conditions were the same as those in Example 1, omitting. The particle size of the particles is 80-200 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com