Method for preparing lithium-manganese silicate of cathode material of lithium-ion battery

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of preparation of a new type of lithium-ion battery positive electrode material-lithium manganese silicate, can solve the problems that the electronic conductivity and tap density are difficult to increase at the same time, and are difficult to meet, and achieve excellent electrical conductivity. The effect of chemical properties, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of lithium manganese silicate lithium ion battery cathode material that the present invention relates to, its steps are as follows:

[0023] 1. Mix lithium salt, manganese salt and orthosilicate in polyol in proportion, heat to boiling point in the reflux system and react for 5-48 hours, then transfer to an open container and dry at 80-180°C to obtain powder Li: Mn: Si molar ratio in the powdery mixed precursor is (1.9-2.1): (0.95-1.05): 1, and the amount of polyol added is 5 to 30 times the volume of orthosilicate ;

[0024] 2) Mix the powdery mixed precursor with the additives and ball mill (the mixing process is carried out in conventional mixing equipment, such as planetary ball mill, bedroom mill, inclined mill, cone mixer or three-dimensional mixer for 1 to 24 hours ), the addition of additives is 1-40% of the mass of the powdery mixed precursor, after ball milling, it is pressed into tablets, and then put into heat treatment equipment (any...

Embodiment 1

[0029] Mix 10.2g of lithium acetate, 12.24g of manganese acetate, and 11.2ml of tetraethyl orthosilicate in 110ml of ethylene glycol and place in a reflux system, heat to 196°C for 12 hours, then slowly cool to room temperature, Transfer to a watch glass and dry at 100°C for 24 hours to obtain a precursor. The dried precursor is mixed with 1 g of sucrose and ball milled for 24 hours. The equipment used for ball milling is a planetary ball mill with an autopropagation speed of 250 r / min. Press the fully ground mixed powder into tablets with a pressure of 10MPa, under the protection of 1L / min argon atmosphere, raise it to 700°C at a rate of 1°C / min, keep it at this temperature for 10h, and then cool it to room temperature. get Li 2 MnSiO 4 sample.

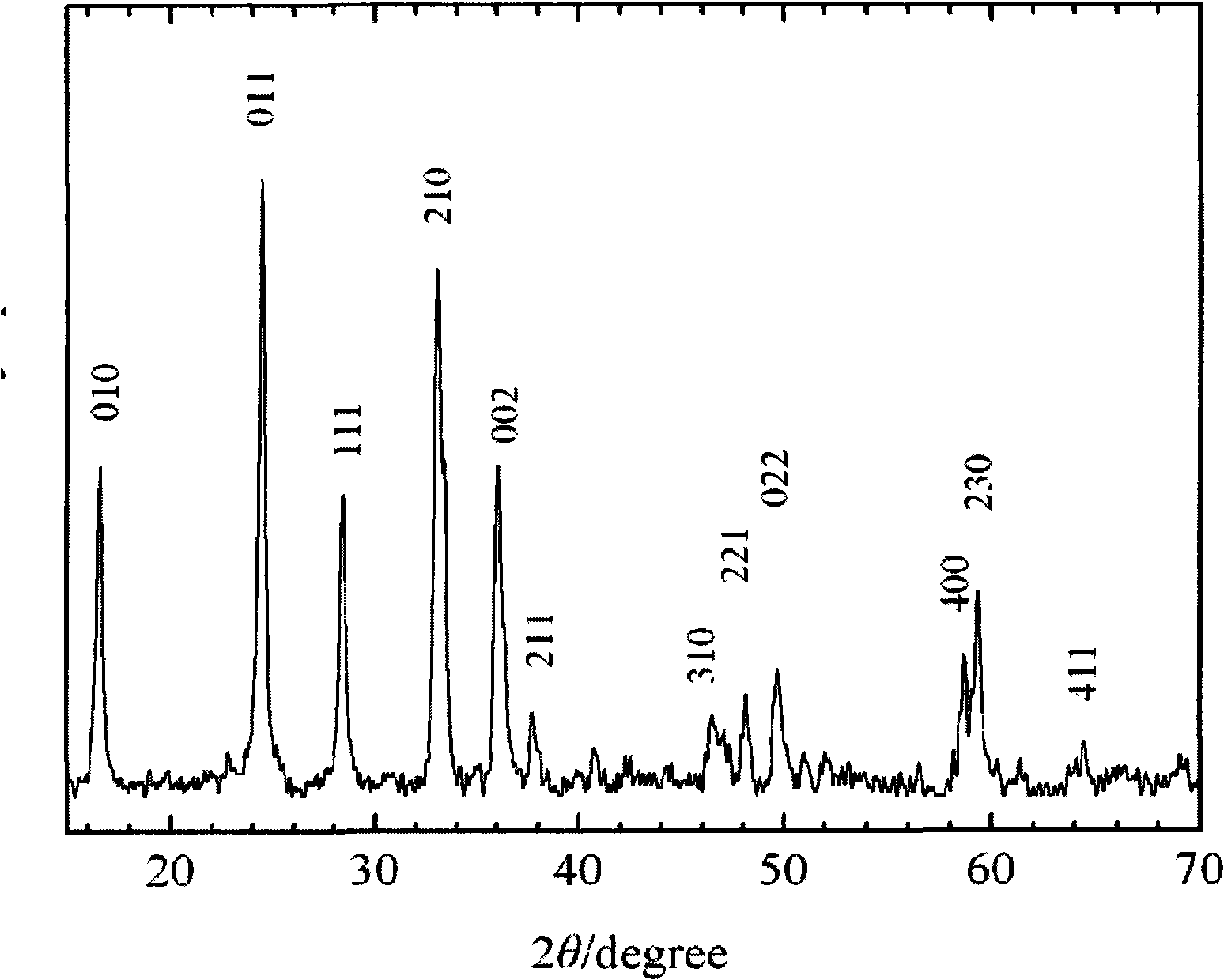

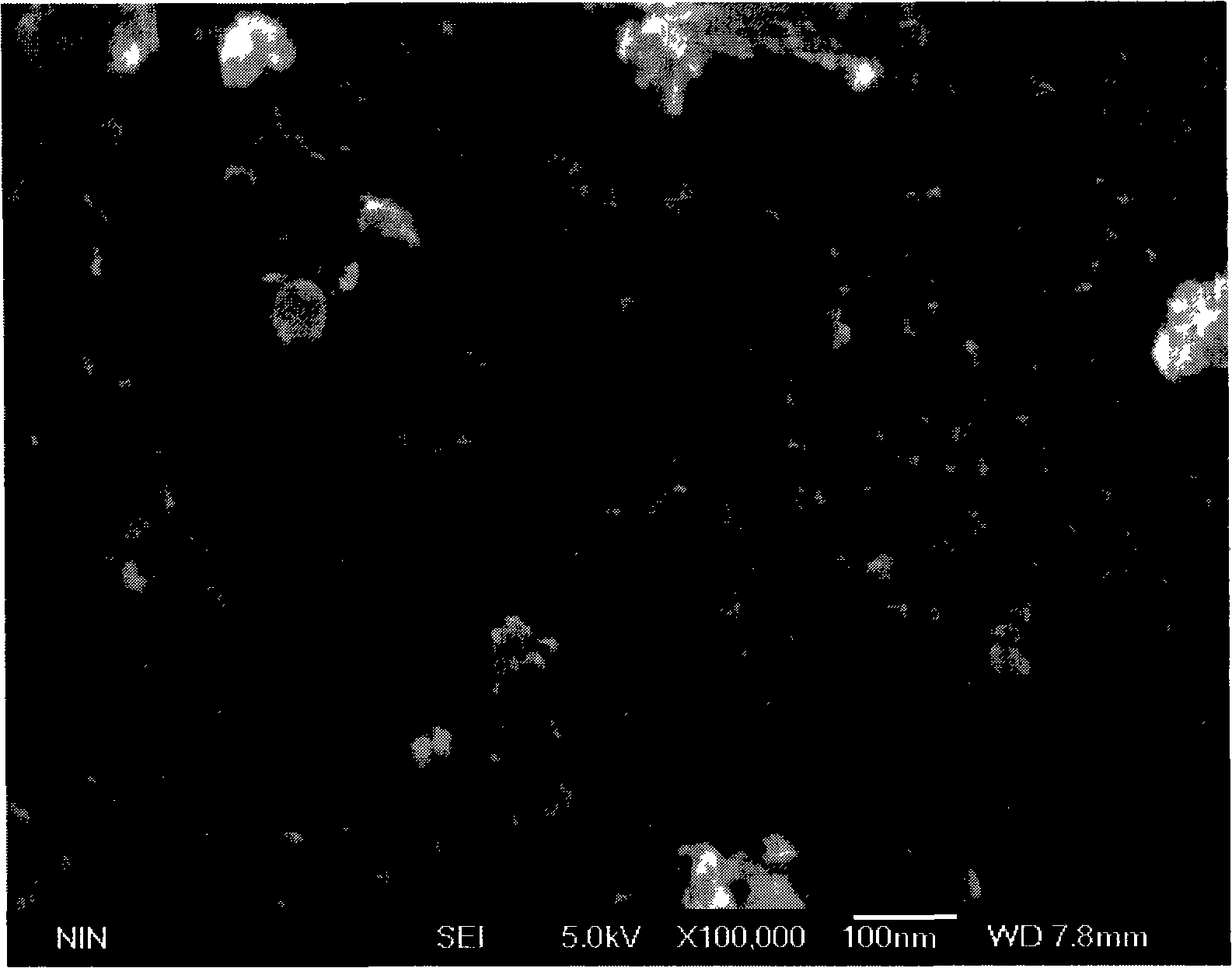

[0030] figure 1 It is the XRD spectrum of the lithium manganese silicate obtained in Example 1, all the diffraction peaks can correspond to the characteristic peaks of lithium manganese silicate, and no diffraction peaks of impuri...

Embodiment 2

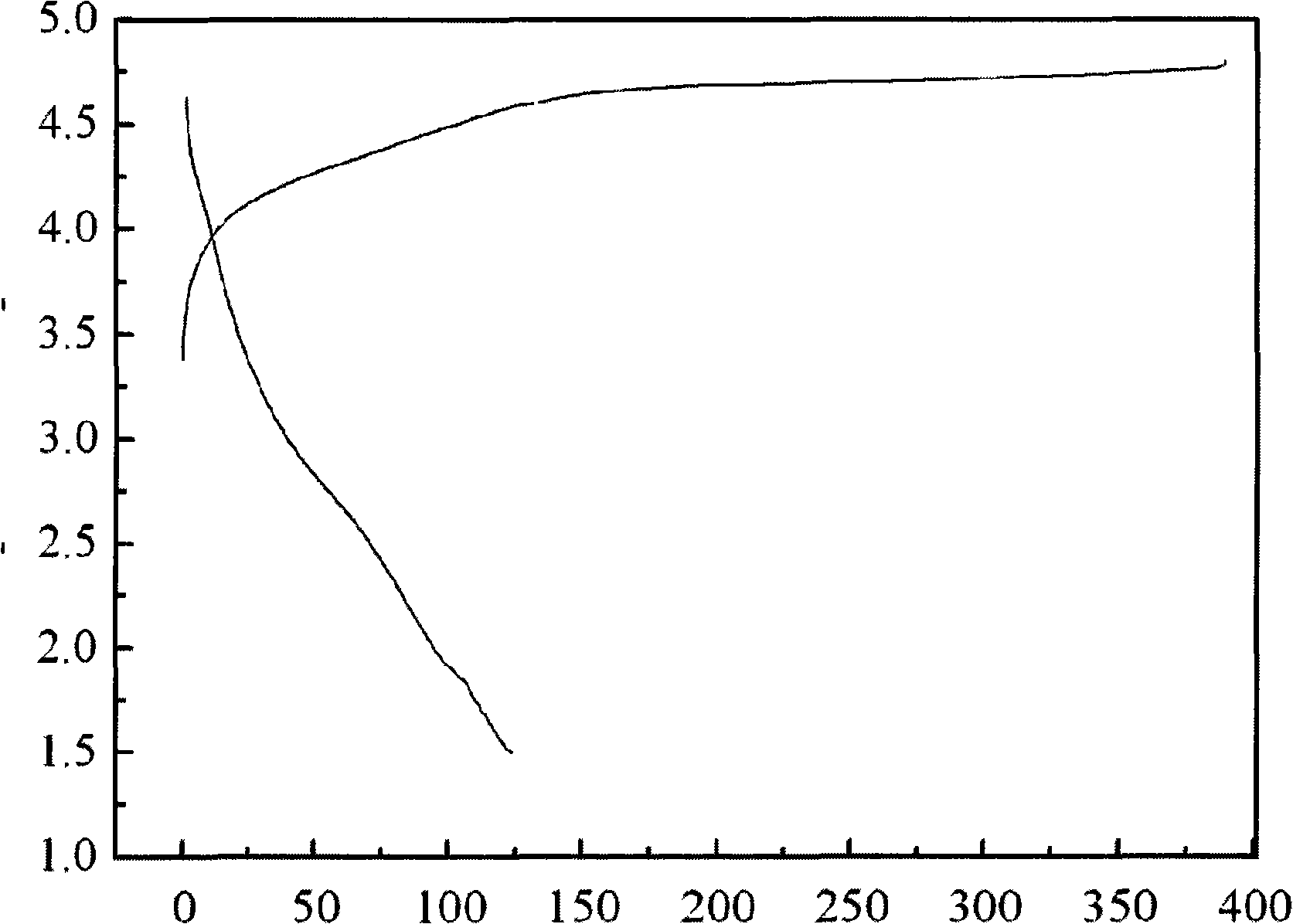

[0033] Mix 2.4g of lithium hydroxide, 12.24g of manganese acetate, and 11.2ml of ethyl orthosilicate in 200ml of ethylene glycol and place them in a reflux system, heat to 196°C, react for 15 hours, then slowly cool to room temperature, and transfer to Dried in a watch glass at 150°C for 24 hours to obtain the precursor. The dried precursor was mixed with 1.5g sucrose and ball milled for 24 hours. The equipment used for the ball mill was a planetary ball mill with an autopropagation speed of 200r / min. Press the well-ground mixed powder into tablets with a pressure of 10 MPa, and raise it to 650 °C at a rate of 2 °C / min under the protection of 1 L / min of argon atmosphere, keep it at this temperature for 12 hours, and then cool to room temperature to obtain Li 2 MnSiO 4 sample. Test its electrochemical performance according to the method of embodiment 1, as image 3 As shown, its first cycle reversible capacity is 123mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com