Method for preparing sodium alginate/ chitosan sustained-release microcapsule by external gelation

A technology of sodium alginate and calcium chloride chitosan, which is applied in the preparation of microspheres, microcapsule preparations, pharmaceutical formulations, etc. In order to improve the drug content and encapsulation efficiency, narrow particle size distribution and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Disperse 100ml of doxorubicin (mass concentration of 1.5%) sodium alginate (mass concentration of 1.5%) physiological saline solution into 500ml of edible vegetable oil containing 0.5% span 80, adjust the motor speed to 400r / min and stir for 15 minutes. Add 500ml of 1% calcium chloride and 0.5% chitosan (the degree of deacetylation is 95.3%) to initiate the gelation reaction of sodium alginate. After continuing to stir for 30 minutes, the degreasing device adopts the sedimentation self-floating method to thoroughly remove the alginate. Release the oil on the surface of the microcapsule. Collect and dry naturally to obtain doxorubicin sodium alginate chitosan sustained-release microcapsules. According to "The Pharmacopoeia of the People's Republic of China" 2005 edition appendix VA (appendix 28) ultraviolet-visible spectrophotometry, measure the drug load of doxorubicin in sodium alginate / chitosan sustained-release microcapsules at 481nm, record The content of doxorubic...

Embodiment 2

[0023] Disperse 10ml of sodium alginate normal saline solution with a mass fraction of 3% into 80ml of edible vegetable oil containing 0.5% span80, adjust the motor speed to 1000r / min and stir for 20 minutes. Adding mass concentration is respectively 10% calcium chloride, 1% chitosan (deacetylation degree is 85.7%) solution 50ml causes sodium alginate gelation reaction, after continuing to stir for 60 minutes, collect slow release microcapsule, pass The deoiling device adopts the sedimentation self-floating method to completely remove the oil on the surface of the sustained-release microcapsules, collects, and naturally dries to obtain the sustained-release microcapsules.

Embodiment 3

[0025] Disperse 10ml of sodium alginate normal saline solution with a mass fraction of 1% into 30ml of edible vegetable oil containing 1% span 80, adjust the motor speed to 500r / min and stir for 15 minutes. Adding mass concentration is respectively 3% calcium chloride, 0.5% chitosan (deacetylation degree is 98.2%) solution 50ml causes sodium alginate gelation reaction, after continuing to stir for 20 minutes, collect slow-release microcapsule, pass The deoiling device adopts the sedimentation self-floating method to completely remove the oil on the surface of the sustained-release microcapsules, collects, and naturally dries to obtain the sustained-release microcapsules.

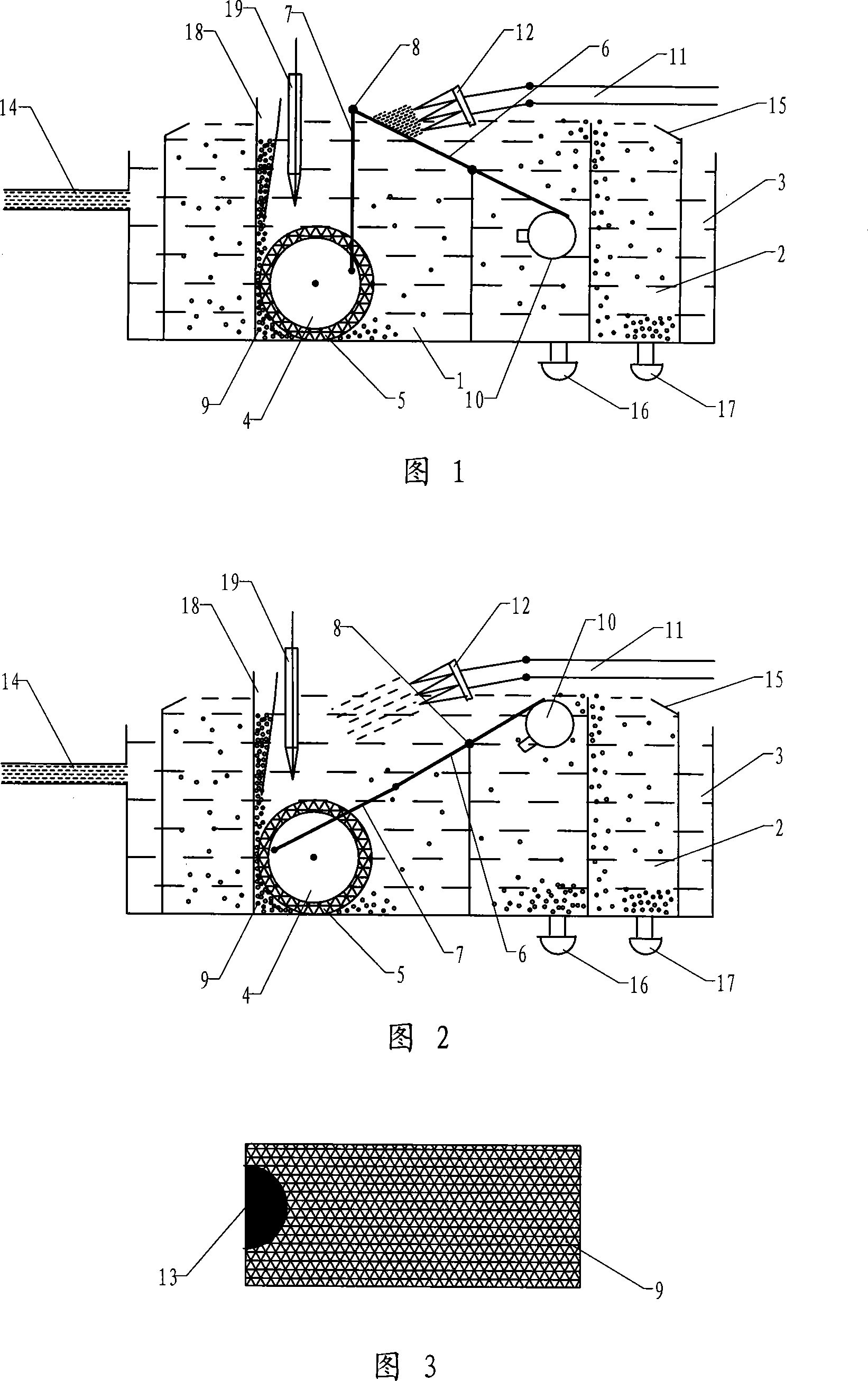

[0026] The degreasing device described in the above-mentioned embodiments 1-3 is shown in Figure 1-3, and it is made up of degreasing tank 1, sedimentation tank 2 and oil collection tank 3, and its height is set from high to low from inside to outside, In the degreasing pool 1, there is a rotating column 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com