Method for preparing precursor of positive material of nickel manganese cobalt multi-element lithium ion battery

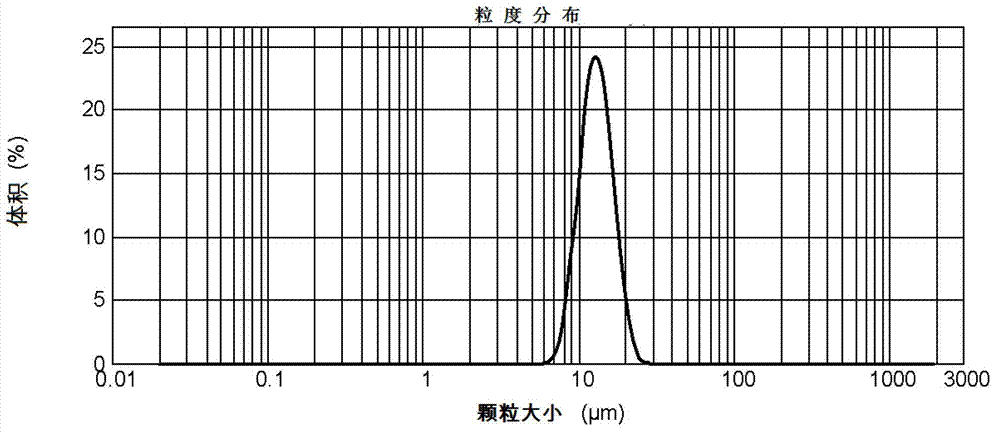

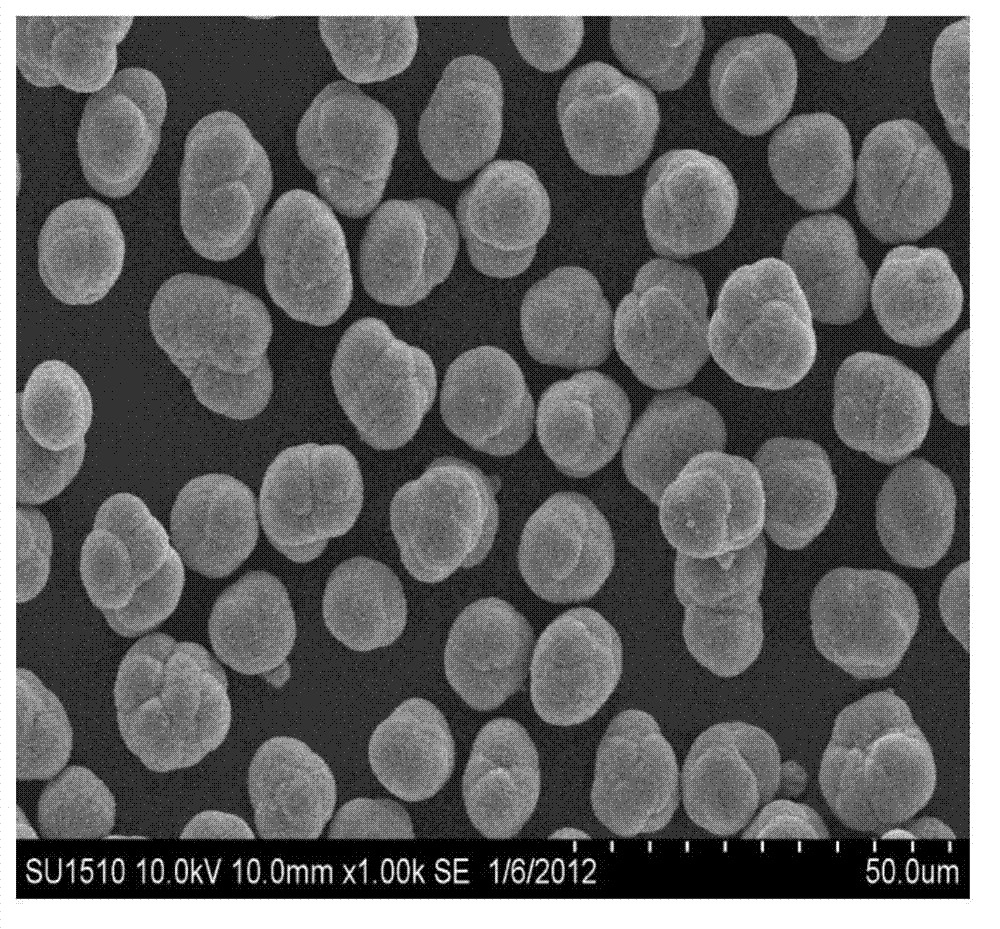

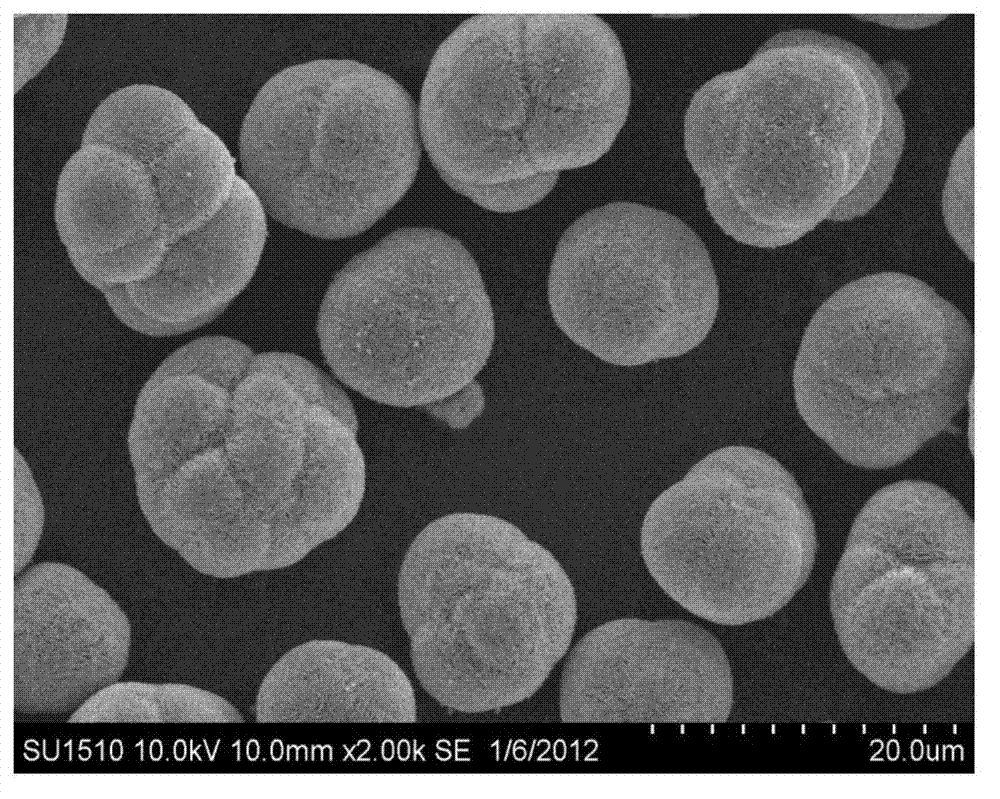

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, circuits, electrical components, etc., can solve environmental pollution and other problems, achieve narrow particle size distribution, no risk of ammonia nitrogen pollution, and good spherical shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Using deionized water as a solvent, nickel sulfate, cobalt sulfate, and manganese sulfate 2+ :Co 2+ :Mn 2+ Molar ratio = 0.5:0.2:0.3 dissolved in a ratio, configured into a compound salt solution with a total metal molar concentration of 2mol / L;

[0025] (2) Prepare sodium hydroxide with deionized water to make 4mol / L sodium hydroxide alkaline solution;

[0026] (3) Add the compound salt solution prepared in (1) and the alkali solution prepared in (2) into the reaction vessel, control the reaction temperature at 50°C, and the reaction stirring speed at 300 rpm, and control the salt and alkali Solution drop rate, so that the pH value of the reaction system is controlled at 9-11.

[0027] (4) After reacting for 60 hours, continue to stir for 2 hours, let stand for 4 hours, filter, and wash with deionized water until Na + The content is below 0.03%, and then dried at a temperature of 120°C to obtain the desired precursor for nickel-cobalt-manganese multi-element li...

Embodiment 2

[0034] Use deionized water as solvent, nickel nitrate, cobalt nitrate, manganese nitrate by Ni 2+ :Co 2+ :Mn 2+ Molar ratio = 0.8:0.1:0.1 ratio dissolved, configured into a compound salt solution with a total metal molar concentration of 0.8mol / L;

[0035] (2) Prepare sodium hydroxide with deionized water to make 2mol / L sodium hydroxide alkaline solution;

[0036] (3) Add the compound salt solution prepared in (1) and the alkali solution prepared in (2) into the reaction vessel, control the reaction temperature at 50°C, and the reaction stirring speed at 300 rpm, and control the salt and alkali Solution drop rate, so that the pH value of the reaction system is controlled at 9-10.

[0037] (4) After reacting for 60 hours, continue to stir for 2 hours, let stand for 2 hours, filter, and wash with deionized water until Na + The content is below 0.03%, and then dried at a temperature of 115°C to obtain a precursor for nickel-cobalt-manganese multi-element lithium-ion battery c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com