Synthesis method of guanidine organic magnetic ionic liquid and method for constructing magnetic aqueous two phase system by using guanidine organic magnetic ionic liquid

A magnetic ionic liquid, ionic liquid technology, applied in separation methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of difficulty in two-phase separation, unfavorable mass and heat transfer, and high price, and achieve good application prospects and high cost. The effect of enrichment factor and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

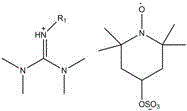

[0035] Synthesis:

[0036] (1) 4-Hydroxy-2,2,6,6-tetramethylpiperidine oxide (4-OH-tempo) was dissolved in chloroform, stored in ice bath, and slowly added dropwise while the system was stirring Add equimolar amounts of chlorosulfonic acid to the solution; then continue to stir at room temperature for 12 hours, evaporate under reduced pressure; wash the solid product with dichloromethane, remove the organic solvent by evaporating under reduced pressure, and obtain tempo-OSO 3 H, stored under vacuum.

[0037] (2) Will work with tempo-OSO 3 H Equimolar amounts of 1,1,3,3-tetramethylguanidine (TMG) dissolved in ethanol / acetone, mixed with tempo-OSO 3 The ethanol / acetone solution of H was mixed and stirred, and the organic solution was evaporated under reduced pressure to obtain a red viscous liquid, which was the final product, which was dried and stored in vacuum.

Embodiment 2

[0039] Synthesis of 2:

[0040] (1) 4-Hydroxy-2,2,6,6-tetramethylpiperidine oxide (4-OH-tempo) was dissolved in chloroform, stored in ice bath, and slowly added dropwise while the system was stirring The chlorosulfonic acid of equimolar amount was added into the solution, and the system began to precipitate solids at this time; then continued stirring at room temperature for 23 hours, and evaporated under reduced pressure; the solid product was washed with dichloromethane, and the organic solvent was removed by evaporation under reduced pressure to obtain tempo- OSO 3 H, stored under vacuum.

[0041] (2) Will work with tempo-OSO 3 H Equimolar amounts of 1,1,3,3-tetramethylguanidine (TMG) dissolved in ethanol / acetone, mixed with tempo-OSO 3 The ethanol / acetone solution of H was mixed and stirred, and the organic solution was evaporated under reduced pressure to obtain a red viscous liquid, which was the final product, which was dried and stored in vacuum.

Embodiment 3

[0043] Synthesis:

[0044] (1) 4-Hydroxy-2,2,6,6-tetramethylpiperidine oxide was dissolved in chloroform, stored in ice bath, and an equimolar amount of chlorine was slowly added dropwise while the system was stirring. Sulfonic acid was added to the solution, and the system began to precipitate solids at this time; the system continued to stir for 12 hours at room temperature, and evaporated under reduced pressure; the solid product was washed with dichloromethane, evaporated under reduced pressure to remove the organic solvent, dissolved in ethanol / acetone, added, etc. Molar amount of NaOH ethanol solution, the organic solvent was removed by evaporation under reduced pressure, and the crude product was dissolved in acetone for recrystallization to obtain tempo-OSO 3 Na, the product was filtered and stored in vacuum.

[0045] (2) Dissolve 1,1,3,3-tetramethylguanidine (TMG) in ethanol, add an equimolar amount of ethyl bromide, stir and reflux at 70°C for 13 hours; evaporate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com