Differential type flexible piezoresistive device based on conductive polymer composite

A technology of conductive polymers and composite materials, applied in the field of measurement, can solve problems such as inability to improve sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

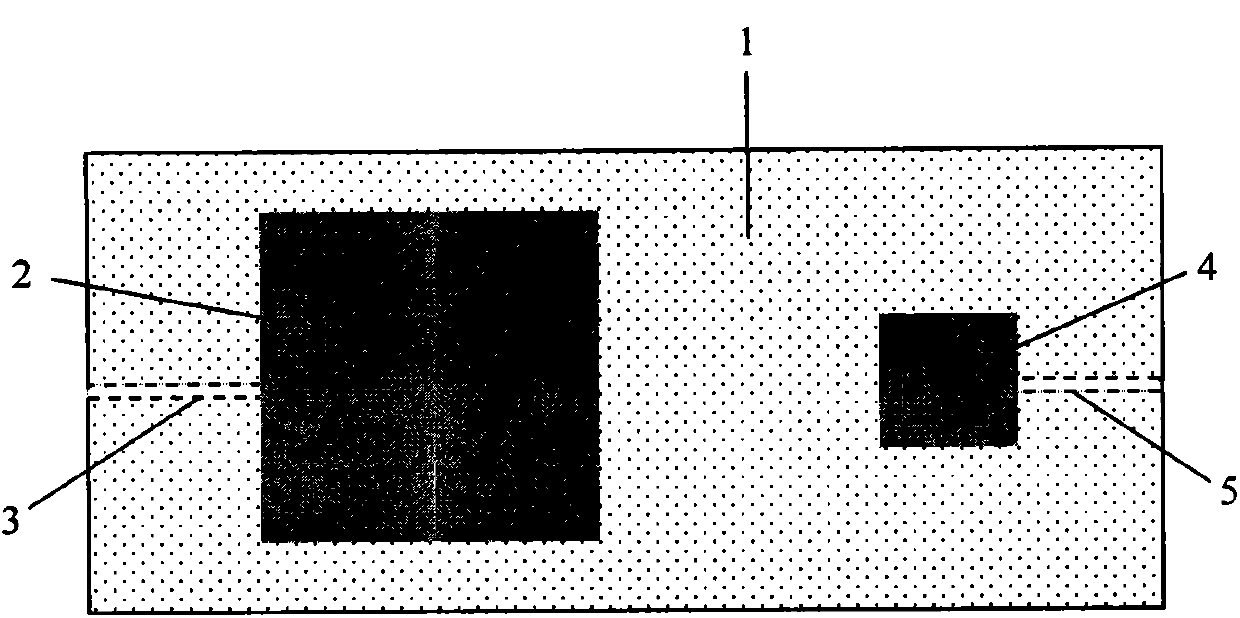

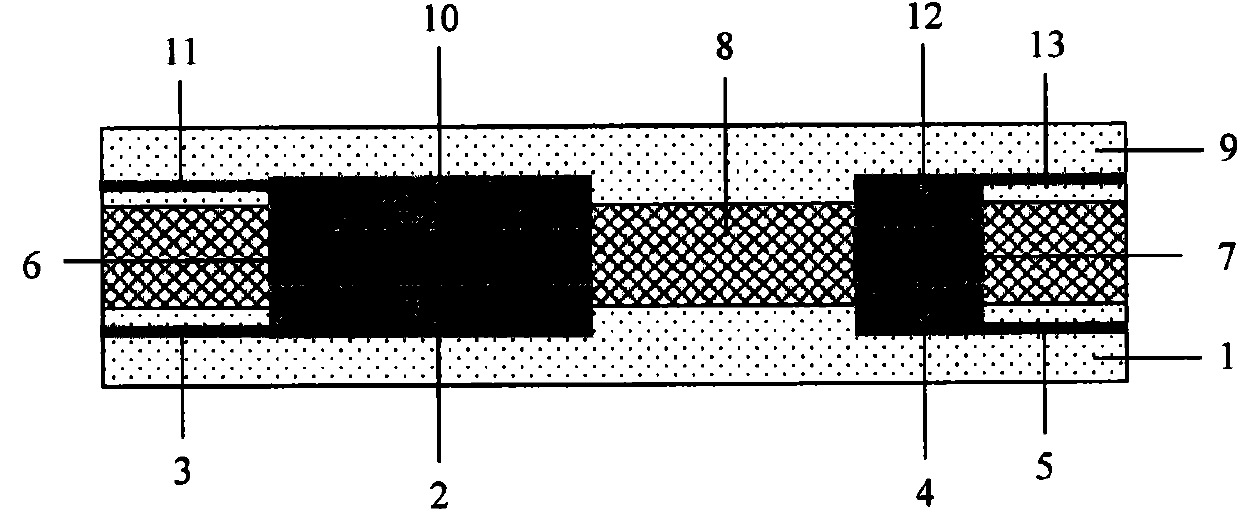

[0014] Lay the lower electrode of the incremental piezoresistive unit and the lower electrode of the progressive piezoresistive unit on the polyimide film as the bottom packaging film; The areas are 24 square millimeters and 8 square millimeters respectively; the bottom packaging film is fixed on the rotating platform for later use; the conductive carbon black powder (specific surface area is 780 square meters per gram) and room temperature vulcanized silicone rubber are mixed according to the ratio of 0.08:1. The mass ratio is mixed to form a carbon black-filled silicone rubber composite gel-like viscous material with increasing piezoresistive properties, and it is dropped into the lower electrode of the incremental piezoresistive unit of the bottom packaging film fixed on the rotating platform On the surface, an incremental piezoresistive effect film with a thickness of 0.08 mm was formed by spin coating, and formed after vulcanization for 60 hours; the incremental piezoresis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com