Method for preparing conductive polymer composite with one-dimensional oriented porous structure

A conductive polymer and porous structure technology, applied in the direction of material resistance, etc., can solve the problems of easy cracking of the film, low stability, small action area, etc., and achieve the effect of low equipment requirements, high production efficiency, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

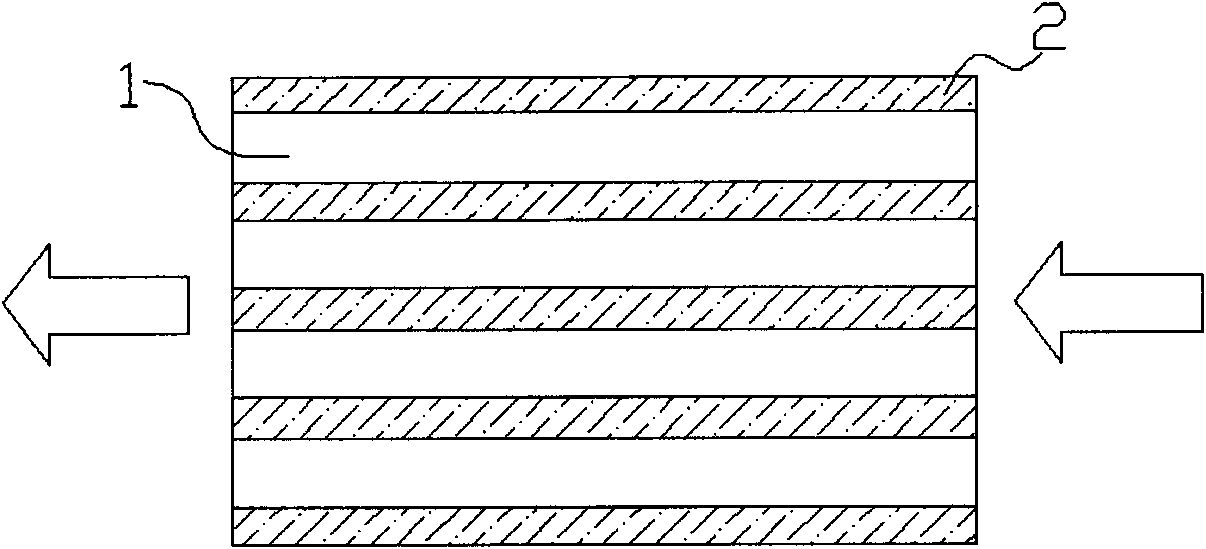

Method used

Image

Examples

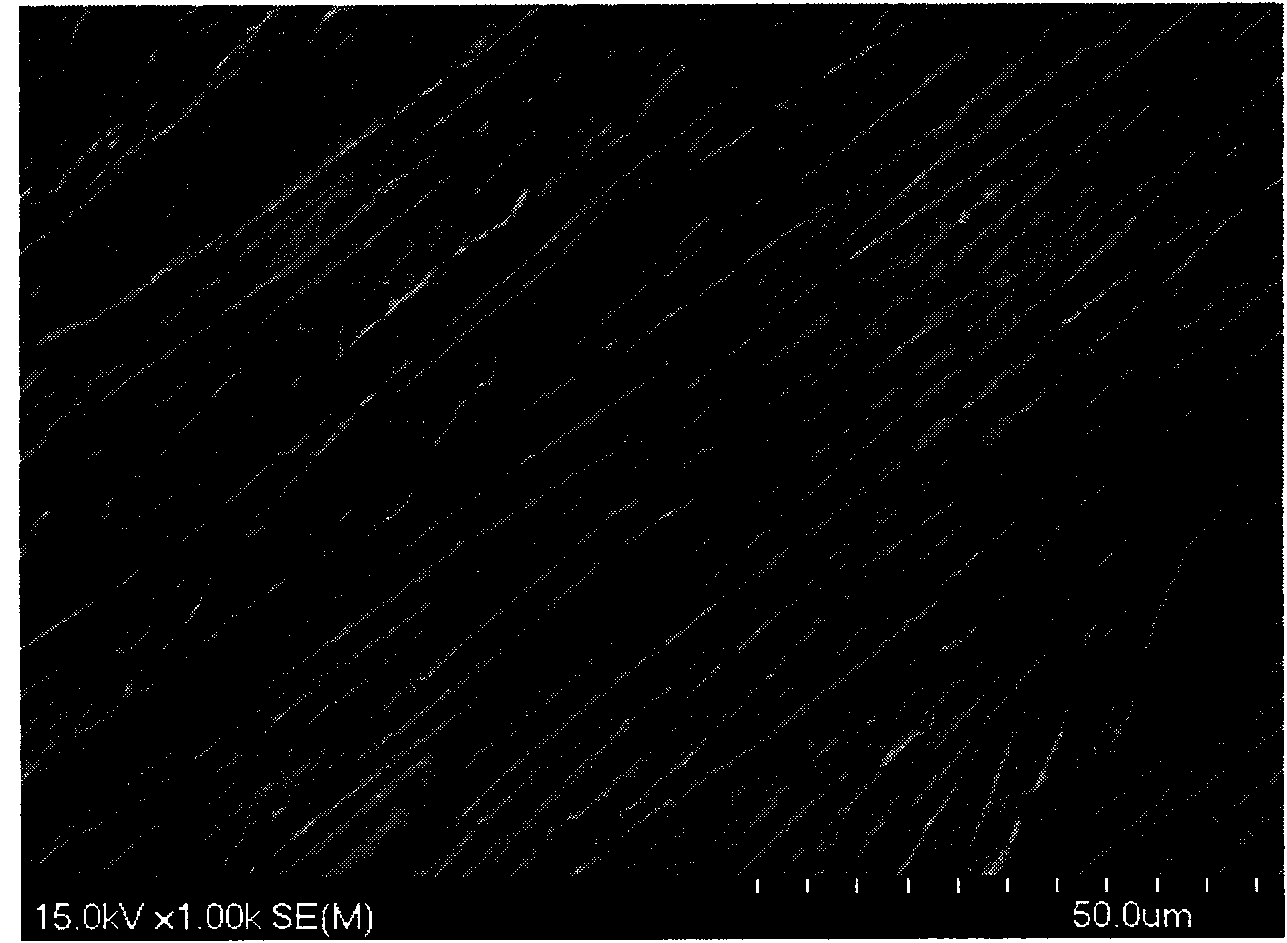

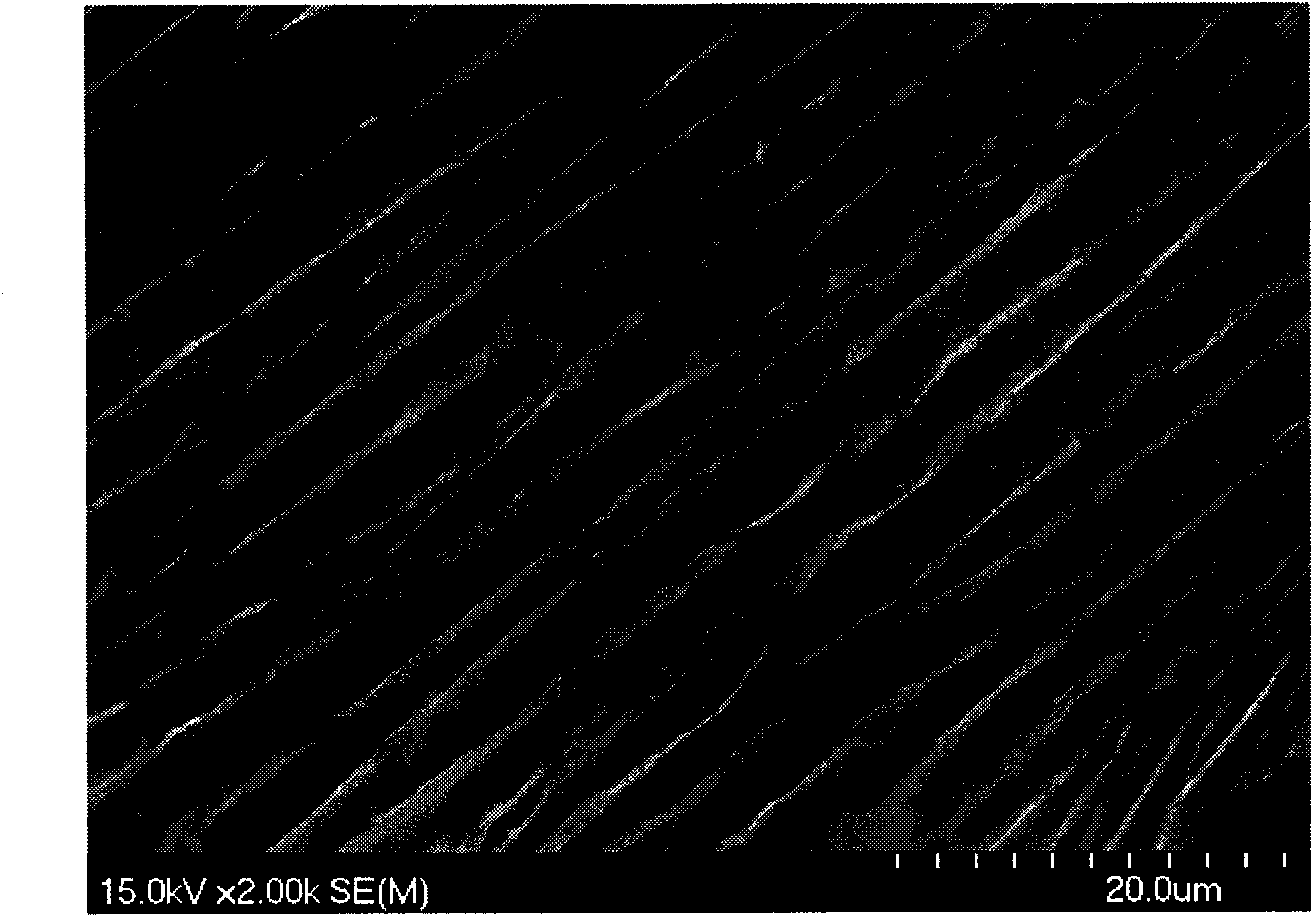

Embodiment 1

[0031] In this embodiment, the conductive particles used are CNTs (model S1212, produced by Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, 50-80 nanometers in diameter, and aspect ratio greater than 500), and the soluble polymer matrix used is PVA (model is 0588, produced by Taiwan Changchun Company), the polymer solvent used is distilled water.

[0032] The test equipment includes:

[0033] Ultrasonic vibrator, model KS-600, Ningbo Maritime Department Kesheng Ultrasonic Equipment Co., Ltd.; freeze dryer, model FD-1C, Beijing Detianyou Technology Development Co., Ltd.; scanning electron microscope (SEM), model Hitachi S-4700 , Hitachi, Japan; Insulation resistance tester, ①Model TH2683, Changzhou Tonghui Electronics Co., Ltd., ②Model ZC-36, Shanghai Jingke Instrument Sixth Factory; Digital Multimeter, Model MY64, Dongguan Huayi Instrument Technology Limited company.

[0034] The preparation and testing method includes the following steps:

[0035] 1) Suspension pr...

Embodiment 2

[0042] In this embodiment, the conductive particles used are CB (model VXC-605, produced by Cabot Corporation, USA, with a DBP absorption value of 148±15cm 3 / 100g), the soluble polymer matrix used is PVA (model 0588, produced by Taiwan Changchun Company), and the polymer solvent used is distilled water.

[0043] The test equipment used is the same as in the first embodiment.

[0044] The preparation and testing method includes the following steps:

[0045] 1) Suspension preparation: Weigh 1g of CB, 100g of distilled water, 0.5g of surfactant, pour into a clean container, mechanically stir for 1h, then ultrasonically vibrate for 20min, continue stirring; weigh a certain amount of PVA, add to In the aqueous solution after ultrasonic vibration, stir and ultrasonic vibration until all PVA is dissolved and a uniform suspension is formed;

[0046] 2) Directional freezing: After pouring the suspension prepared in step 1) into a special container, slowly immerse the container in liquid nitro...

Embodiment 3

[0052] In this embodiment, the conductive particles used are CNTs (model S 1212, produced by Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, diameter 50-80 nanometers, aspect ratio greater than 500), and the soluble polymer used is water-based polyurethane (WPU) , The solvent used is water.

[0053] The test equipment used is the same as in the first embodiment.

[0054] The preparation method includes the following steps:

[0055] 1) Suspension preparation: Weigh 1 g of CNTs, 100 g of water-based polyurethane emulsion, 0.5 g of surfactant, and pour it into a clean container, mechanically stir for 1 hour, then ultrasonically vibrate for 20 minutes, and continue stirring until a uniform suspension is formed;

[0056] 2) Directional freezing: After pouring the suspension prepared in step 1) into a special container, slowly immerse the container in liquid nitrogen at a speed of 2mm / s through a fixed-speed moving device, and place it in liquid nitrogen for 15 minutes aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com