Method for developing flexible pressure sensitive probe with side electrode

A side-mounted, soft technology, applied in the field of sensors, can solve the problems of reduced softness and inapplicability of the sensitive probe part of the sensor, and achieve the effects of saving development costs, reducing development costs, and reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

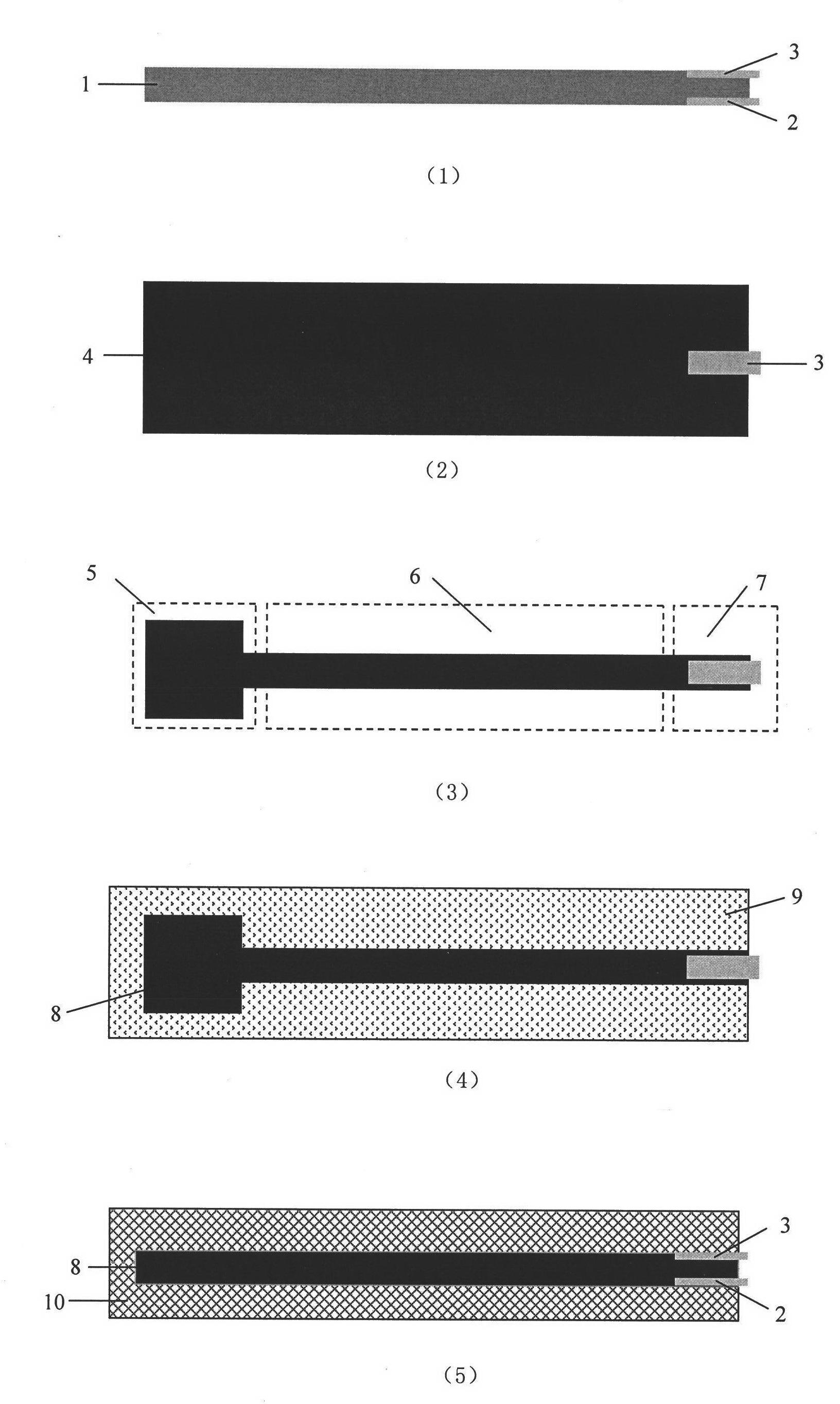

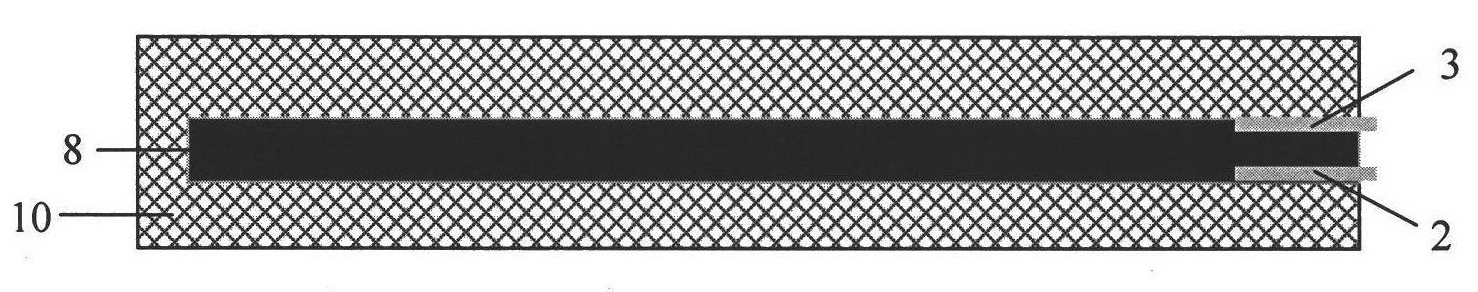

Method used

Image

Examples

Embodiment 1

[0020] A. After drying the multi-walled carbon nanotubes with a diameter of 20-40 nanometers and a length of 5-15 microns, mix them with room temperature vulcanized silicone rubber in a mass ratio of 0.03:1, and add n-hexane solvent in a volume ratio of 1 : 40. The mixed solution of multi-walled carbon nanotubes / room temperature vulcanized silicone rubber / n-hexane solvent is subjected to high-power mechanical stirring, and at the same time, it is supplemented by ultrasonic oscillation to disperse the multi-walled carbon nanotubes in the mixed solution. Under the action of dibutyltin dilaurate and ethyl orthosilicate, a multi-walled carbon nanotube / room temperature vulcanized silicone rubber gel-like sticky substance is formed.

[0021] B. Place a metal sheet with a thickness of 20 microns and a width of 0.2 cm on a smooth and rigid flat plate as the lower electrode, and place it on the lower platform of the microcomputer-controlled lifting platform. Spread the jelly prepared ...

Embodiment 2

[0024] A, after drying the nano-carbon black with a specific surface area of 780 square meters per gram, mix it with room temperature vulcanized silicone rubber in a mass ratio of 0.08:1, and add n-hexane solvent, and the volume ratio is 1:60. The nano-carbon black / room temperature vulcanized silicone rubber / n-hexane solvent mixed solution is mechanically stirred with high power, and at the same time, it is supplemented by ultrasonic vibration to disperse the nano-carbon black in the mixed solution. Under the action of dibutyltin dilaurate and ethyl orthosilicate, a nano-carbon black / room temperature vulcanized silicone rubber colloidal sticky substance is formed.

[0025] B. Place a metal sheet with a thickness of 20 microns and a width of 0.25 cm on a smooth and rigid flat plate as the lower electrode, and place it on the lower platform of the microcomputer-controlled lifting platform. Spread the jelly prepared in step A evenly on a smooth and rigid flat plate, and make th...

Embodiment 3

[0028] A, after drying the graphene with a specific surface area of 50 square meters per gram, mix it with room temperature vulcanized silicone rubber in a mass ratio of 0.04:1, and add n-hexane solvent, and the volume ratio is 1:50. The graphene / room temperature vulcanization silicone rubber / n-hexane solvent mixed solution is subjected to high-power mechanical stirring, and at the same time, it is assisted by ultrasonic vibration to disperse the graphene in the mixed solution. Under the action of dibutyltin dilaurate and tetraethyl orthosilicate, a graphene / room temperature vulcanized silicone rubber gel-like sticky substance is formed.

[0029] B. Place a metal sheet with a thickness of 20 microns and a width of 0.15 cm on a smooth and rigid flat plate as the lower electrode, and place it on the lower platform of the microcomputer-controlled lifting platform. Spread the jelly prepared in step A evenly on a smooth and rigid flat plate, and make the length of the overlapping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com