Conductive polymer composite material and preparation method thereof

A technology of conductive polymer and composite material, applied in the field of polymer modification materials, can solve the problems of thermoplastic elastomers, low volume resistivity, and inability to meet the application requirements of conductive polymer materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

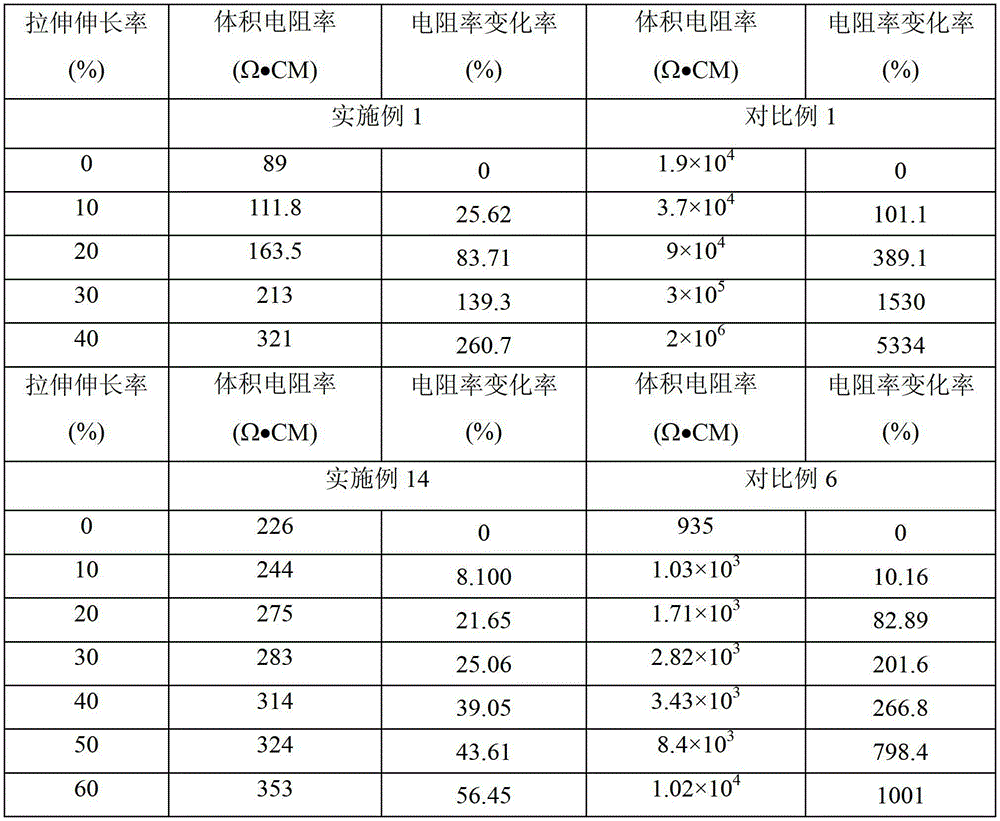

Embodiment 1

[0045]Carboxylated nitrile powder rubber (Sinopec Beijing Research Institute of Chemical Industry, VP501, average particle size 90nm; gel content 91%wt), carbon nanotubes (Beijing Tiannai Technology Co., Ltd., FloTube9000, average diameter 11nm, average length 10μm ; aspect ratio of 900, multi-walled carbon nanotubes), polypropylene (Ningbo Nengzhiguang New Material Technology Co., Ltd., GPM200A, melting point 163 ° C), the metal alloy is tin-bismuth alloy (Beijing Sanhe Dingxin High-tech Development Co., Ltd. company, melting point 138°C), Antioxidant 1010 and Antioxidant 168 (manufactured by Ciba Gage, Switzerland), and mix thoroughly in a blender. Wherein the weight ratio of powder rubber to polypropylene is 70 / 30, the total weight ratio of carbon nanotubes to polypropylene and powder rubber is 2 / 100, the volume ratio of the metal alloy to the volume of polypropylene and powder rubber is 2 / 100, Antioxidants 1010 and 168 were 0.2% and 0.4% of the total weight of powdered rub...

Embodiment 2

[0049] Except that the volume ratio of powder rubber and polypropylene is 60:40, all the other are the same as in Example 1, and the gained polypropylene / powder rubber / carbon nanotube / metal composite is tested for volume resistivity, and the test results are shown in Table 1. .

Embodiment 3

[0051] Except that the volume ratio of powder rubber and polypropylene is 40:60, all the other are the same as in Example 1, the gained polypropylene / powder rubber / carbon nanotube / metal composite material is tested for volume resistivity, and the test results are shown in Table 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com