Metal organic frame/conductive polymer composite material and preparation and application thereof

A metal-organic framework, conductive polymer technology, used in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problem of difficult implementation of fibrous electrode substrates, and achieve stable long-term service life, good mechanical flexibility, excellent Effects of Capacitive Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing a metal-organic framework / conductive polymer composite material, comprising the steps of:

[0037] (1) Synthesis of metal organic framework materials;

[0038] (2) preparing an electrolyte solution, the electrolyte solution comprising a monomer of a conductive organic substance and the metal-organic framework material described in step (1);

[0039] (3) Immerse the carbon fiber bundle in the electrolyte described in step (2), and electrodeposit a metal-organic framework / conductive polymer composite material on the carbon fiber bundle by potential scanning cyclic voltammetry in one step, and the conductive polymer is The polymer obtained after the monomer of the conductive polymer in step (2) is polymerized.

[0040]The metal-organic framework material in step (1) can be of various types such as ZIF-8, UiO-66, ZIF-67, HKUST-1, etc., and its particle size is 50-900nm in nanoscale. The general preparation method is: mix the metal salt and the organ...

Embodiment 1

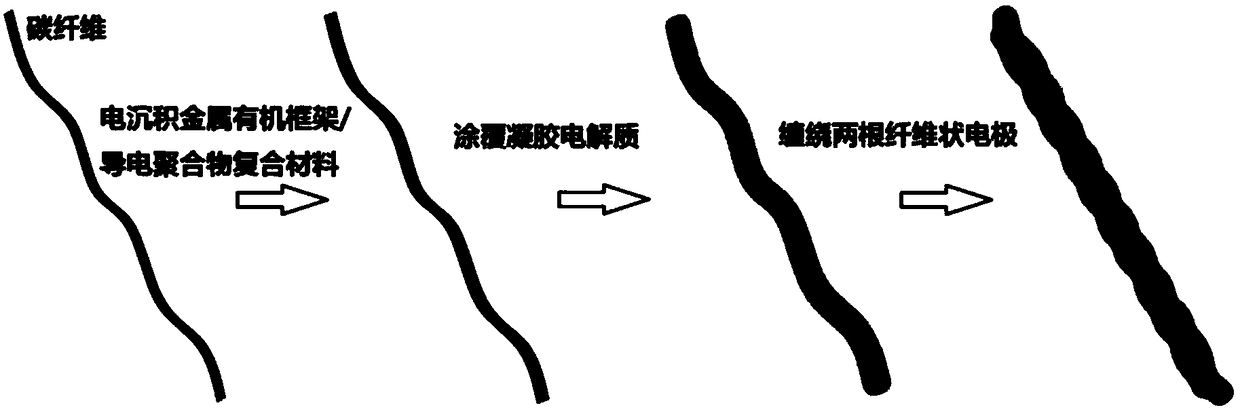

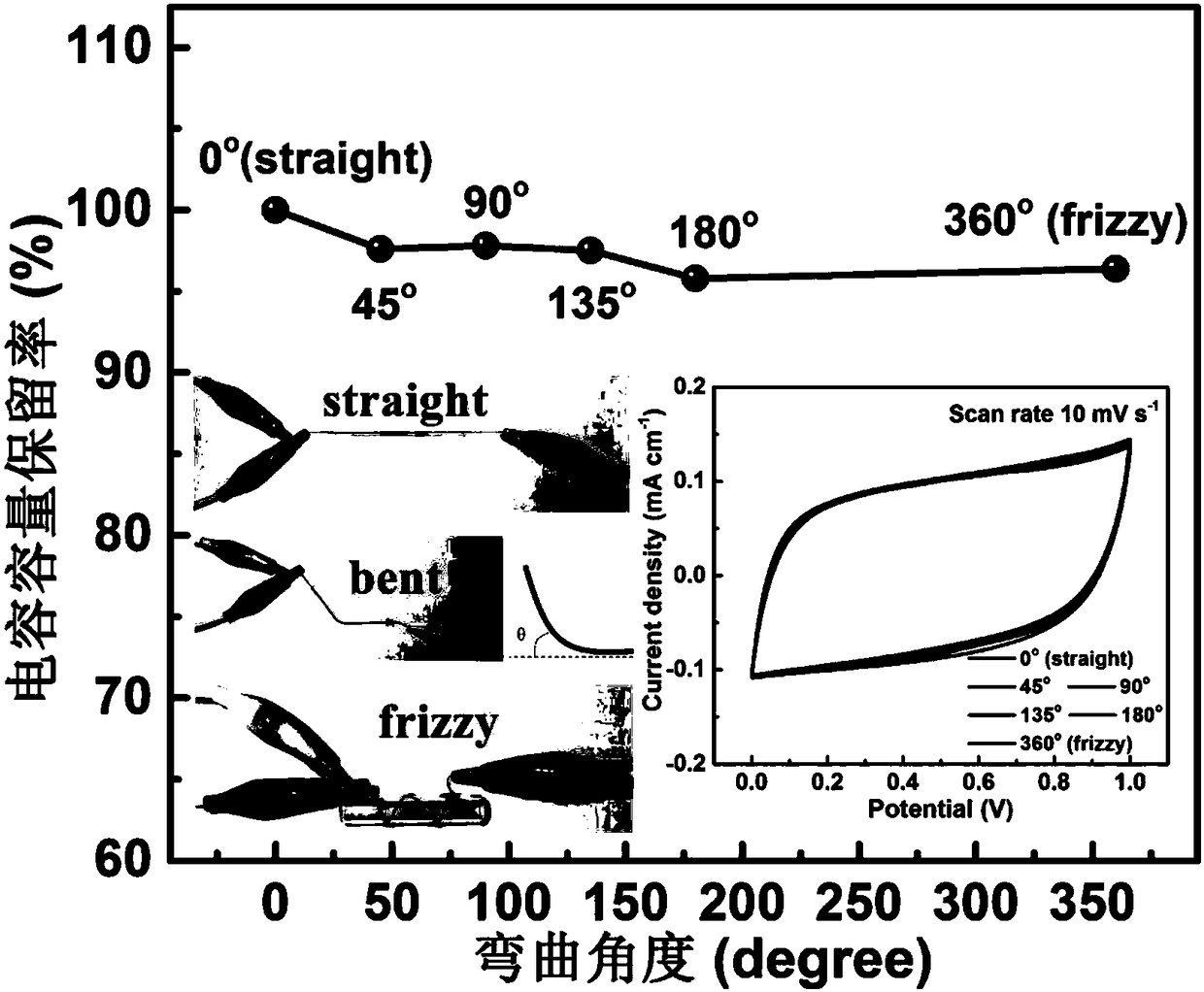

[0053] A fabrication method for braidable, flexible, fibrous supercapacitors such as figure 1 shown, including the following steps:

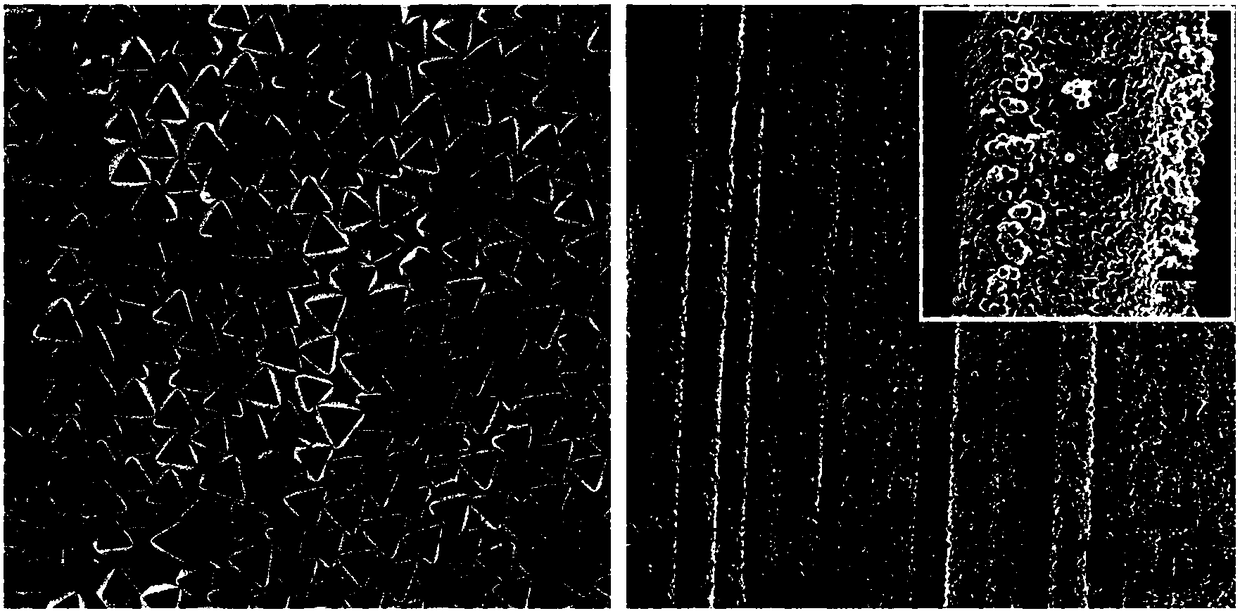

[0054] Step 1, 5mL 16mM zirconium chloride (ZrCl 4 ) in dimethylformamide (DMF) dispersion and 5mL 16mM phthalic acid (H 2 BDC) DMF solution was ultrasonically mixed, 1.75mL of acetic acid was added dropwise, the mixture was placed in a sealed glass reaction bottle, and reacted at 95°C for 12 hours, the resulting white precipitate was washed with DMF, purified in methanol, kept at 50°C, every Refresh methanol once every 4 hours, wash with methanol after 3 times, and dry in vacuum at 100°C for 12 hours to obtain MOFs material UiO-66 nanoparticles. The microscopic appearance is as follows: figure 2 (a), its particle diameter is about 500nm.

[0055] Step 2: heating and refluxing the carbon fiber bundles in acetone for 24 hours, washing with deionized water, and drying for later use. 0.1 M pyrrole monomer, 5 mg / mL UiO-66 and 1 mg / mL dopamine w...

Embodiment 2

[0075] A fabrication method for braidable, flexible, fibrous supercapacitors such as figure 1 shown, including the following steps:

[0076] Step 1, 5mL 16mM zirconium chloride (ZrCl 4 ) DMF dispersion and 5mL 16mM phthalic acid (H 2 BDC) DMF solution was ultrasonically mixed, 1.75mL of acetic acid was added dropwise, the mixed solution was placed in a sealed glass reaction bottle, and reacted at 95°C for 12 hours, the obtained white precipitate was washed with DMF, purified in methanol, kept at 50°C, every Methanol was renewed every 4 hours, washed with methanol after 3 times, and dried in vacuum at 100°C for 12 hours to obtain MOFs material UiO-66 for future use.

[0077] Step 2: heating and refluxing the carbon fiber bundles in acetone for 24 hours, washing with deionized water, and drying for later use. 0.5 M aniline monomer, 5 mg / mL UiO-66 and 1 mg / mL dopamine were mixed and ultrasonically dispersed in phosphate buffer to prepare an electrodeposition electrolyte for use....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com