High-entropy alloy powder conductive polymer composite material and manufacturing method thereof

A technology of conductive polymer and high-entropy alloy, which is applied to conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of high price, low price and high resistivity of silver powder, and achieve good wettability and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Prepare the high-entropy alloy powder conductive polymer composite material according to the following formula in parts by weight:

[0015] Al 0.5 CoCrCuFeNiTi high entropy alloy powder 20

[0016] SBR 80

[0017] Preparation method: Al 0.5 CoCrCuFeNiTi high-entropy alloy powder and styrene-butadiene rubber are mixed, mixed in an internal mixer, and granulated. The obtained sample was pressed into a film at 220°C, and the resistivity of the sample was measured by a four-point probe method. The values are shown in Table 1.

Embodiment 2 to 10

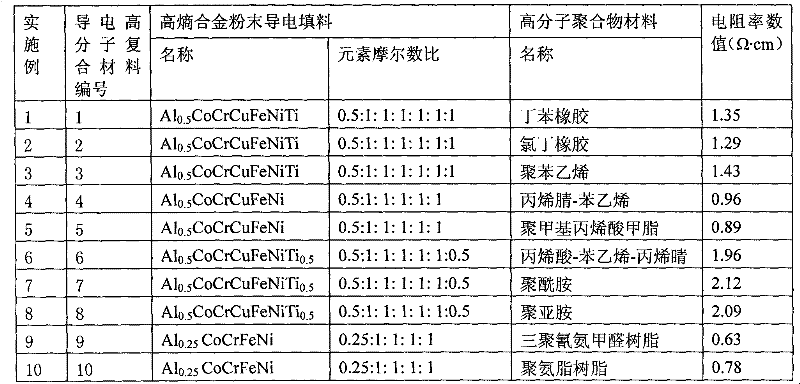

[0019] The manufacturing steps of Example 1 were repeated, but the constituent elements of the high-entropy alloy powder conductive filler and the polymer material were changed to the compositions shown in the conductive polymer composite material numbers 2 to 10 in Table 1. The resistivity test method is the same as in Example 1, and the values are shown in Table 1.

[0020] Table 1 Composition of conductive polymer composite material (weight ratio of high-entropy alloy powder conductive filler to polymer material is 1:4)

[0021]

[0022] In summary, high-entropy alloy powder is a very good conductive filler, which has excellent compatibility with polymer materials. The high-entropy alloy powder conductive polymer composite material of the invention has the characteristics of stability and low cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com