Preparation method of porous conductive polymer material with pressure-sensitive property and application thereof

A porous conductive and polymer technology, which is used in the measurement of the property force of piezoelectric resistance materials, multi-tester circuits, and the use of repetitive force/pulse force to test the strength of materials, etc., which can solve the complex preparation process, poor flexibility, Small compressive strain, etc., to achieve the effect of wide source, long service life and high compressive strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

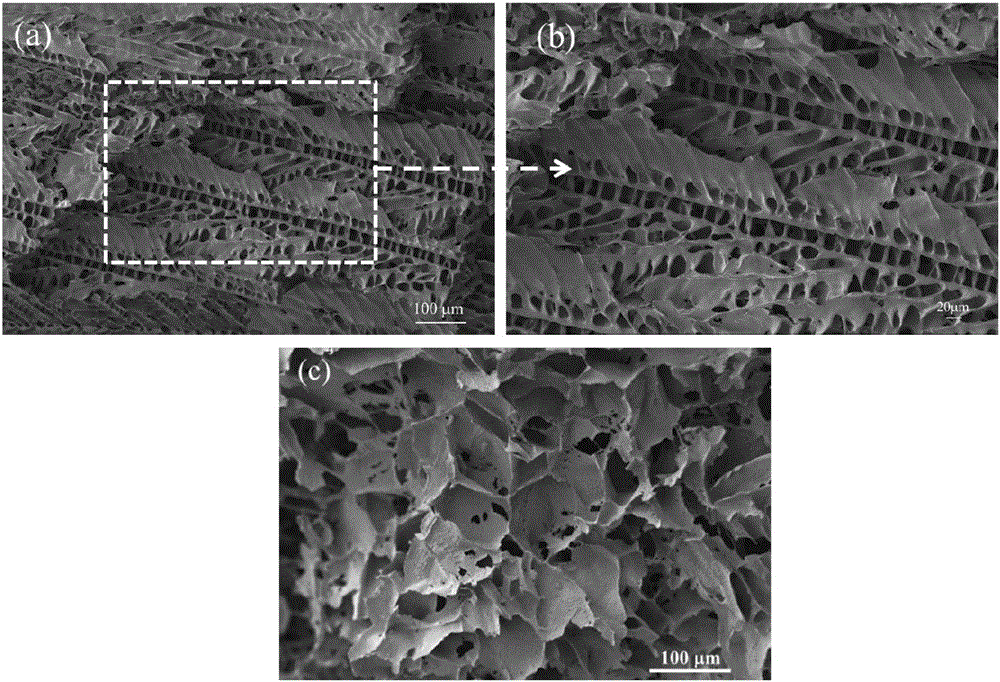

[0035] Example 1 Preparation of porous conductive polymer composites with pressure-sensitive properties

[0036] The specific preparation steps are:

[0037] (1) Drying of raw materials: drying TPU and MWCNTs in a vacuum oven for 8 hours at 80°C;

[0038](2) Preparation of suspension: mix 0.0513g MWCNTs powder and 40ml dioxane in a 100ml beaker, and ultrasonically disperse in a water bath at 15-25°C for 30min to obtain a uniform MWCNTs / dioxane mixture, then Add 2g of TPU to it, stir at 40°C for about 1 hour, and cool to room temperature to obtain a TPU / MWCNTs / dioxane suspension;

[0039] (3) One-way freezing: Pour the suspension into a flat-bottomed glass test tube with a height of 10 cm and a diameter of 2 cm, and seal it with filter paper; then tightly cover the area of the test tube except the bottom with heat-insulating foam and place it on a smooth surface On an iron block whose length, width and height are 10cm, then place the iron block, test tube and heat insulatio...

Embodiment 2-7

[0041] Example 2-7 Preparation of Porous Conductive Polymer Composite Material with Pressure Sensitive Properties

[0042] Each raw material ratio of embodiment 2-7 is as shown in table 1. The specific preparation methods are all the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com