Spinning, processing, and applications of carbon nanotube filaments, ribbons, and yarns

a carbon nanotube and filament technology, applied in the field of spinning, processing, and applications of carbon nanotube filaments, ribbons, yarns, can solve the problems of inconvenient use of fibers made by the cs process, inconvenient use of fibers in applications, and insufficient nanotube manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

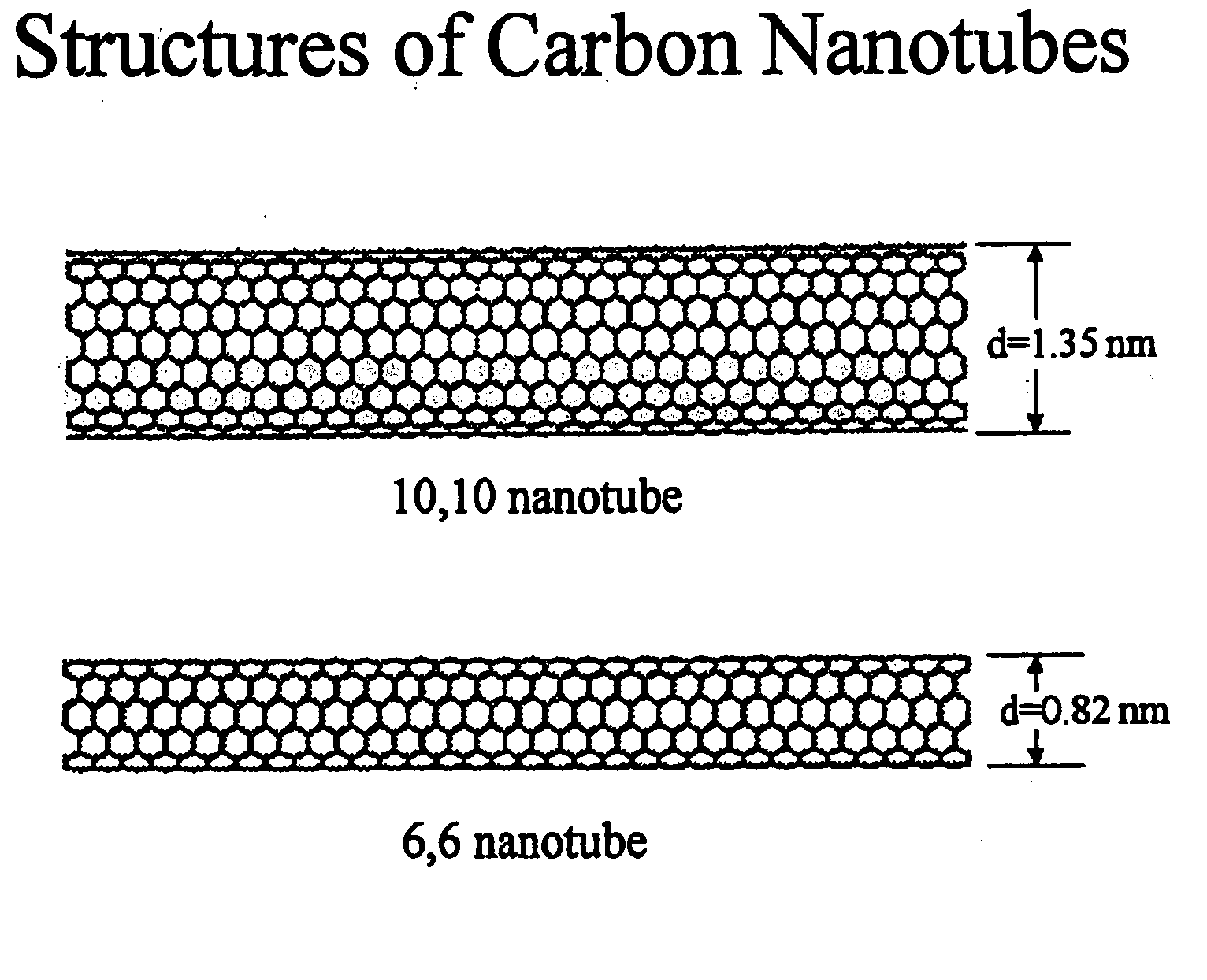

[0075] This example demonstrates the successful use of coagulation spinning to produce long SWNT filaments that are substantially impurity free. The utilized HiPco nanotubes were made by the high-pressure carbon monoxide route described by R. E. Smalley et al. in International Application No. PCT / US99 / 25702. Characterization of this material by Raman spectroscopy showed a nanotube diameter of about 0.84 nm. A 15 g quantity of nanotube mixture, which contains 0.4% (0.060 g) of the HiPco SWNTs and 1.2% (0.18 g) surfactant in 98.4% (14.76 g) distilled water was prepared. The surfactant used was sodium dodecyl sulphate (SDS 151-21-3, purchased from ICN Biomedical, Aurora Ohio). The mixture was sonicated for about 15 minutes by BRANSON MODEL 350 20 kHz sonifier, purchased from Branson Ultrasonic Corporation, Danbury Conn. Sonication of the NT / surfactant / water mixture was accomplished in a 21 cc glass bottle (25 mm inside diameter), which was placed in a cold water bath in order to minimi...

example 2

[0076] The CS process of Example 1 was unsuccessful when the SWNTs used for the spinning solution were highly purified SWNTs obtained by the purification of carbon-arc-synthesized nanotube-containing soot. These purified carbon nanotubes were obtained from CarboLex, Inc, University of Kentucky, Lexington Ky. The nanotube suspension was prepared, sonicated and spun exactly as in Example 1. The spinning did not result in the formation of continuous ribbons or filaments. Rather, the injected stream of nanotube suspension broke up into short lengths upon injection into the PVA bath.

example 3

[0077] The CS process of Example 1 was unsuccessful when the SWNTs used for the spinning solution were highly purified SWNTs obtained by the purification of laser-evaporation produced nanotube-containing soot. These chemically purified carbon nanotubes were purchased from tubes@rice, Rice University and consisted predominately of nanotubes having a diameter of about 1.2 to 1.4 nm. The nanotube suspension was prepared, sonicated, and spun exactly as in Example 1. The spinning did not result in the formation of continuous ribbons or filaments. Rather, the injected stream of nanotube suspension broke up into short lengths upon injection into the PVA bath.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com