Graphene fiber non-woven fabric and preparation method thereof

A technology of graphene fibers and non-woven fabrics, which is applied in the direction of graphene, spinning solution preparation, wet spinning, etc., can solve the problems of restricting electrical conductivity, thermal conductivity, graphene content cannot be high, and performance is limited. Easy batch preparation, simple method, good strength and toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) A graphene oxide dispersion liquid with a concentration of 5 mg / mL is prepared, and the solvent is N, N-dimethylformamide, and it is used as a spinning solution.

[0030] (2) Make the spinning solution enter in the ethyl acetate coagulation liquid through the spinning tube with a diameter of 100 μm at an extrusion speed of 0.04mL / min, and control the coagulation bath rotation speed to be 100rpm, so that the length of the graphene short fiber is maintained at 20~ 40mm, soaked in the coagulation solution for 30 minutes, solidified into filaments, collected by vacuum filtration, placed at room temperature for 5 hours, and dried in vacuum at 60°C for 3 hours to obtain a film composed of graphene oxide fibers.

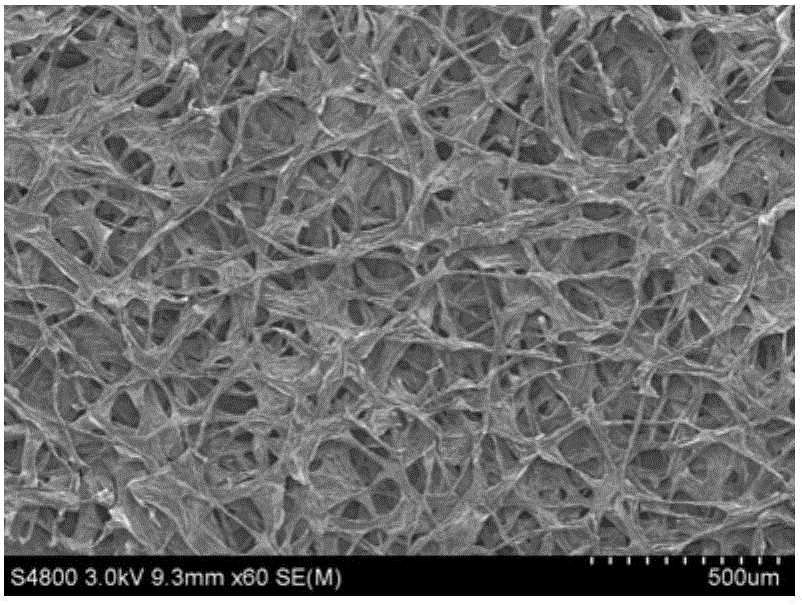

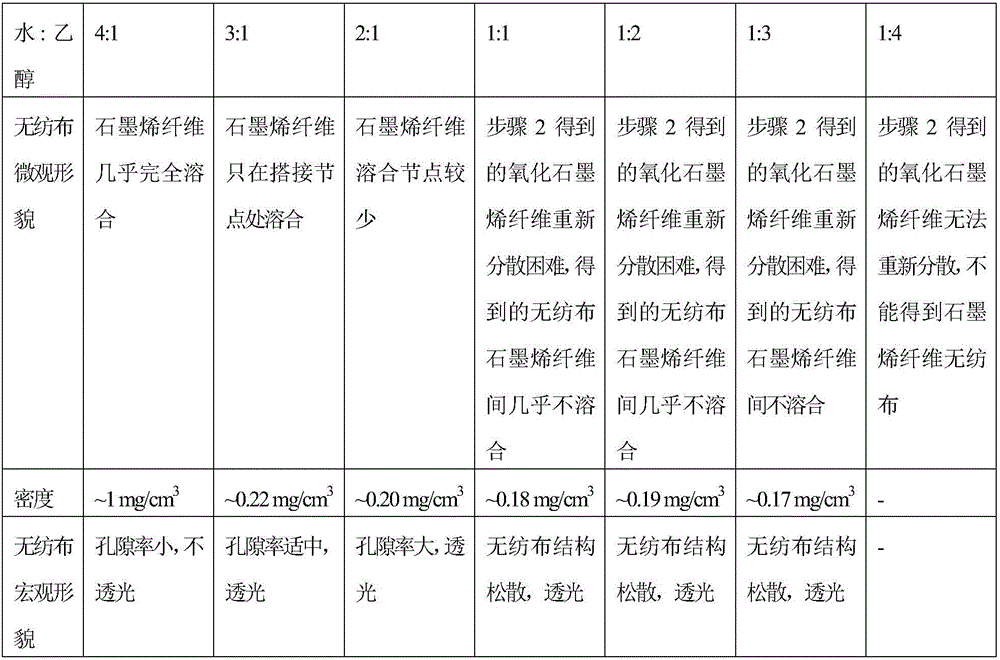

[0031] (3) The dried graphene oxide fiber film is redispersed in a water-ethanol mixture, wherein the volume ratio of water and ethanol used is shown in Table 1. It is determined through experiments that the optimum volume ratio is water:ethanol=3:1, so a suspens...

Embodiment 2

[0037] (1) Prepare a graphene oxide dispersion with a concentration of 6 mg / mL, and use N, N-dimethylformamide as a solvent as a spinning solution.

[0038] (2) Make the spinning solution enter in the ethyl acetate coagulation solution through the spinning tube of 200 μm with the extrusion speed of 0.06mL / min, and control the coagulation bath rotation speed to be 120rpm, so that the length of the graphene short fiber is maintained at 20~ 40mm, soaked in the coagulation solution for 200min, solidified into filaments, collected by vacuum filtration, placed at room temperature for 30h, and vacuum-dried at 60°C for 3h to obtain a film composed of graphene oxide fibers.

[0039] (3) The dried graphene oxide fiber film is redispersed in a mixed solution of water and ethanol with a volume ratio of 1:2 to obtain a suspension of graphene oxide short fibers, which is filtered and deposited through a gauze with a pore size of 500 μm, and washed with ethanol Three times, drying at 80° C. ...

Embodiment 3

[0043] Step 1 is the same as in Example 1.

[0044] Step 2 is: the spinning solution enters the coagulation solution through a spinning tube with a diameter of 200 μm at an extrusion speed of 10 mL / min, enters the ethyl acetate coagulation solution, and controls the rotation speed of the coagulation bath to be 200 rpm so that the length of the graphene short fiber Keep it at 20-40 mm, soak in the coagulation solution for 60 minutes, solidify into filaments, collect by vacuum filtration, leave at room temperature for 20 hours, and vacuum dry at 60°C for 3 hours to obtain a film composed of graphene fibers.

[0045] Steps 3 and 4 are the same as in Example 1.

[0046] After the above steps, the width of the graphene short fibers that make up the graphene fiber non-woven fabric is 60-200 μm, and the density of the non-woven fabric is about 0.21mg / cm 3 , the overall tensile strength is 0.7-0.9MPa, the elongation at break is 2.2%-3.5%, has good toughness, and the electrical conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com