Multifunctional conductive yarn, preparation thereof and application of multifunctional conductive yarn to flexible wearable electronic fabrics

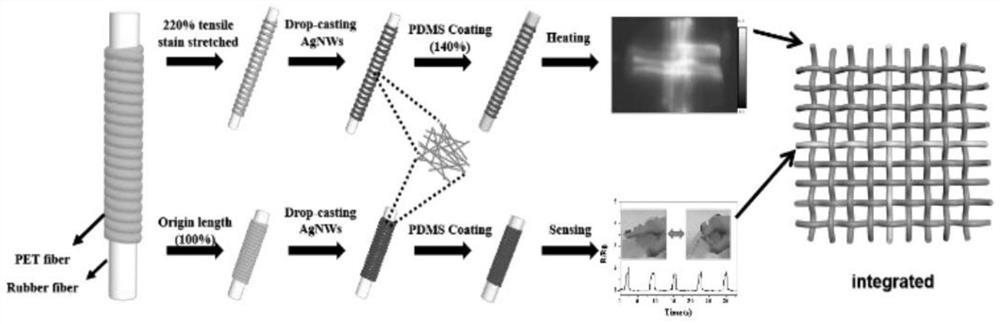

A conductive yarn and yarn technology, applied in the directions of yarn, textile and papermaking, fiber processing, etc., can solve the problems of differential strain sensitivity factor, short life of wearable devices, limited sensitivity to fine deformation, etc., to achieve low cost, good quality Cyclic heating performance, the effect of the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The AgNW stock solution was prepared according to the literature [Chen G, Bi L, Yang Z, et al. Water-based purification of ultrathin silver nanowires toward transparent conductive films with atransmittance higher than 99%. ACS Applied Materials & Interfaces, 2019, 11: 22648-22654.] get. Prepare (A) 220.0 mM NaBr, (B) 210.0 mM NaCl and (C) 505.0 mM PVP K90 in ethylene glycol. Ethylene glycol (116mL), solution A (1mL), solution B (2mL), solution C (15mL) and fresh AgNO 3 (0.6765 g in 15 mL ethylene glycol) was added to a 250 mL flask in an oil bath at room temperature. Then the solution was heated at 300rpm min -1 Stir mechanically for 30 min. After stirring, the temperature of the oil bath was slowly raised to 180C within 20-25min. At the same time, during the heating process, nitrogen (150mL min -1 ) into the solution. When the temperature reached 180°C, the nitrogen was turned off and the temperature of the oil bath was set to 170°C. After 10 min, stirring was s...

Embodiment 2

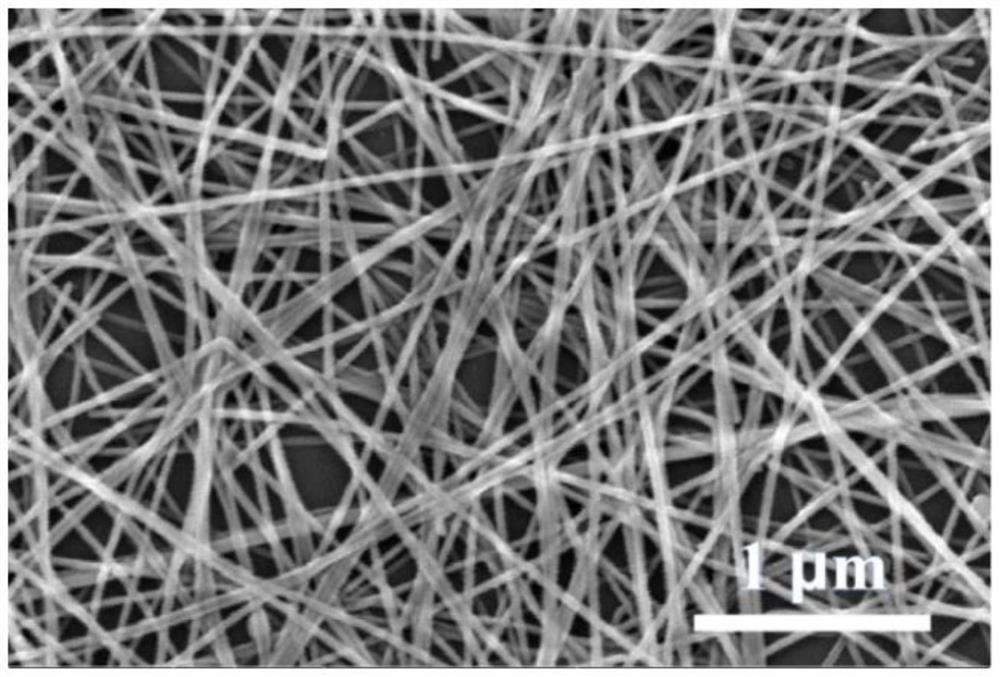

[0052] Pour 150 mL of the AgNW stock solution prepared in Example 1 into a purification device with a filter membrane (8 μm in pore size) and a six-hole stirring paddle, and dilute to 300 mL with absolute ethanol. The stirring speed of the six-hole stirring paddle was set at 900 rpm. During the cleaning process, slowly drop anhydrous ethanol into the purification device to maintain a constant volume of the solution for a total of 40 minutes of cleaning. After cleaning, perform positive pressure filtration first, then add 36mL PVP solution (0.5wt%, K30, molecular weight 55000), shake evenly and then perform positive pressure filtration again, and collect the purified AgNWs for later use. The SEM image of the purified AgNWs is shown in figure 2 shown.

[0053] The purified AgNW was dispersed in ethanol to prepare a certain concentration of AgNW dispersion.

Embodiment 3

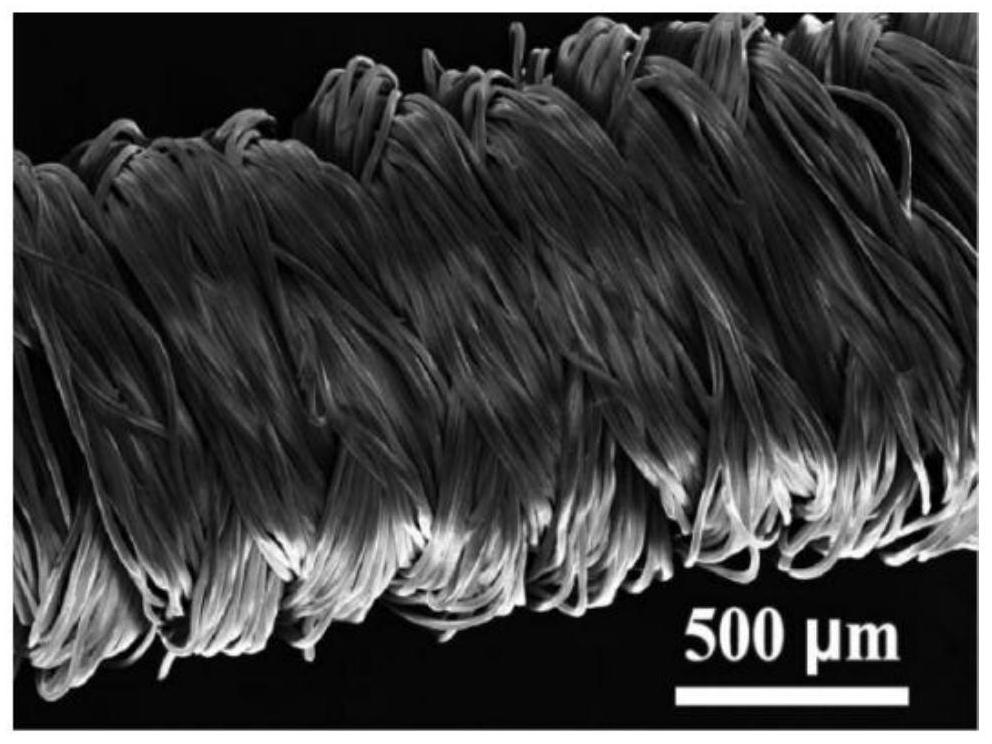

[0055] (1) First, the PET yarn purchased from the market (see image 3 , cut into lengths of 20-24 cm) were ultrasonically cleaned with deionized water and absolute ethanol for 5 min, and dried in air at 60°C. Then, PET yarn is carried out ultraviolet ozone cleaning 10min, obtains the hydrophilic PET yarn with contact angle less than 80 °, the result is as follows Figure 4 shown.

[0056] (2) Stretch the PET yarn treated in step (1) to 220% of its original length and fix it vertically. Get 0.5mL of the silver nanowire dispersion (2mg / mL) obtained in Example 2 and drop it on a The upper section of the PET yarn, let it fall freely along the yarn, coat the yarn, let the silver nanowire dispersion fully wet the yarn, and then dry it completely under hot air immediately. Repeat the same steps for 9 more times to obtain PET yarns (PET / AgNW yarns) containing silver nanowire layers. The photo of PET yarns after AgNW coating shows that the color changes from white to dark green, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com