Turnbuckle type edge leakage proof hydrogen sensor outer housing structure

A hydrogen sensor and side leakage prevention technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of high cost, complex structure, easy to leak, etc., and achieve low cost, good mechanical properties, and no need for sealing circle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

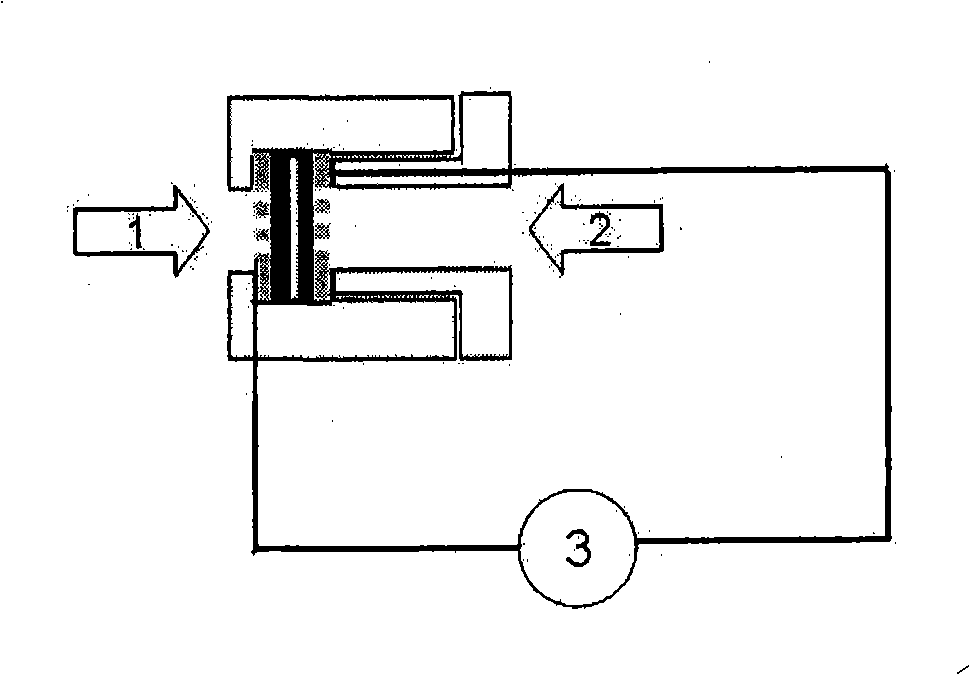

[0023] Refer to attached Figure 5 , Assemble the screw-type hydrogen sensor shell and the membrane electrode to form a hydrogen sensor, wherein the membrane electrode uses Nafion 112 membrane as the electrolyte membrane, uses Pt / C (mass fraction is 40%) as the catalyst, and the cathode and anode Pt loads are 1.2mg respectively / cm 2 , 1.0mg / cm 2 . according to figure 1 The test system shown is tested. Arrow 1 is the mixed gas containing hydrogen at the anode end, and arrow 2 is the fuel gas air at the cathode end. A DC digital voltmeter is used to detect the current between the anode lead and the cathode lead, and the voltage value corresponds to the measured mixed gas. the hydrogen concentration.

example 2

[0025] Refer to attached Figure 5 , Assemble the shell of the screw-type anti-side leakage hydrogen sensor and the membrane electrode to form a hydrogen sensor, and the membrane electrode is the same as in Example 1. Arrow 1 in the figure is the mixed gas containing hydrogen at the anode end, and arrow 2 is the fuel gas oxygen at the cathode end. A DC digital ammeter is used to detect the current between the anode lead and the cathode lead. The current value corresponds to the hydrogen concentration in the measured mixed gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com