Method and device for resistance detection of conductive yarn

A technology of conductive yarn and detection device, applied in the direction of measurement device, measurement of resistance/reactance/impedance, measurement of electrical variables, etc., can solve the problem of uneven production status of conductive yarn, unfavorable product quality stability and improvement, restricting product popularization and application, etc. problem, to avoid the trouble of sample layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0019] The resistance detection method of conductive yarn of the present invention is as follows:

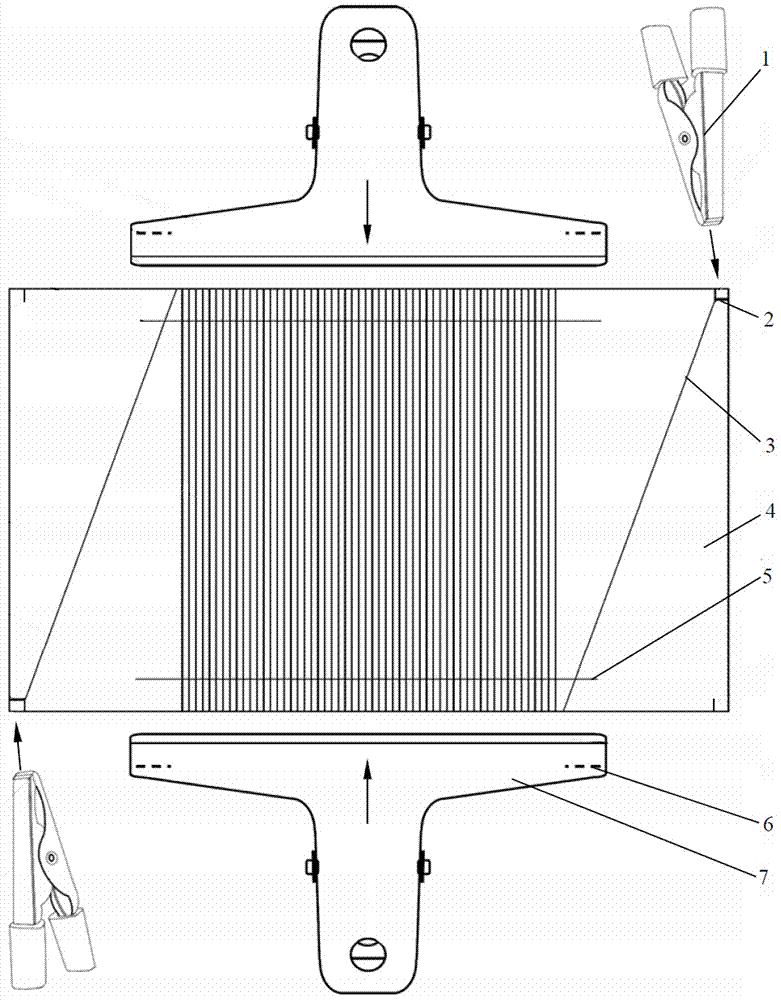

[0020] Wrap a whole conductive yarn sample on the rectangular plate of the insulator, and ensure that there is no contact between the wrapped conductive yarns, so that the wound conductive yarns form a plurality of yarn segments arranged in parallel on one side of the rectangular plate of the insulator;

[0021] There are two yarn end gaps on the insulator rectangular plate to fix the first and last ends of the conductive yarn sample respectively; the cathode and anode conductive clips of the resistance measuring instrument are respectively clamped and connected to the two yarn end gaps to conduct electricity. The end of the yarn sample is used to measure the resistance value of the whole conductive yarn sample;

[0022] The cathode and anode conductive cli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com