Full-fiber base flexible sensor and preparation method and application thereof

A flexible, sensor-based technology, applied in the field of flexible sensors, can solve the problems of insufficient sensor sensitivity, difficult to detect small deformation, limited development and application, etc., and achieve the effects of good reproducibility, easy regulation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

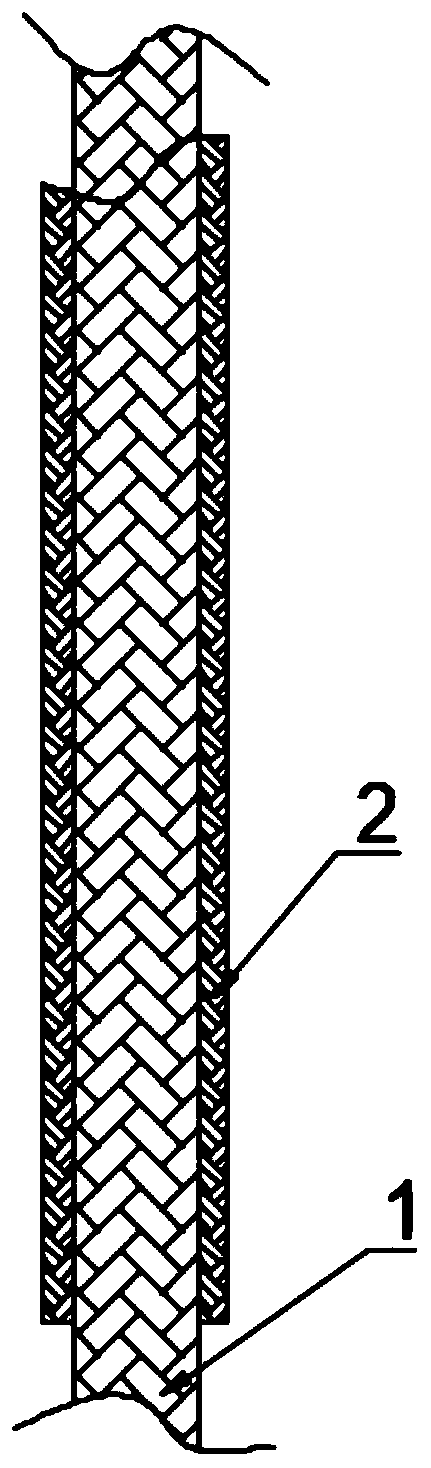

[0037] refer to figure 1 , this embodiment provides an all-fiber-based flexible sensor, the all-fiber-based flexible sensor includes an elastic conductive rope core 1 and a sensing layer 2 woven by conductive yarn and wrapped around the outer periphery of the elastic conductive rope core 1, so The resistance of the elastic conductive cord 1 is lower than 5% of the resistance of the sensing layer 2 .

[0038] The elastic conductive rope core is twisted and braided by a plurality of conductive yarns, the diameter of the elastic conductive rope core is 600 μm, and the elongation rate is greater than or equal to 0.01%.

[0039] The length of the full-fiber-based flexible sensor is 5 cm, the diameter is 2 mm, and the elongation is greater than or equal to 0.01%, and the diameter of the conductive yarn in the full-fiber-based flexible sensor is 300 μm.

[0040] The conductive yarn is a blended yarn, which is prepared by blending polyester fibers and stainless steel fibers at a rati...

Embodiment 2-5

[0048] Embodiments 2-5 provide an all-fiber-based flexible sensor. Compared with Embodiment 1, the difference is that the diameter of the elastic conductive rope core is changed to test the breaking strength of a single sensing material, and other operations are the same , which will not be repeated here, the specific experimental conditions, parameters and performance test results are shown in the table below.

[0049]

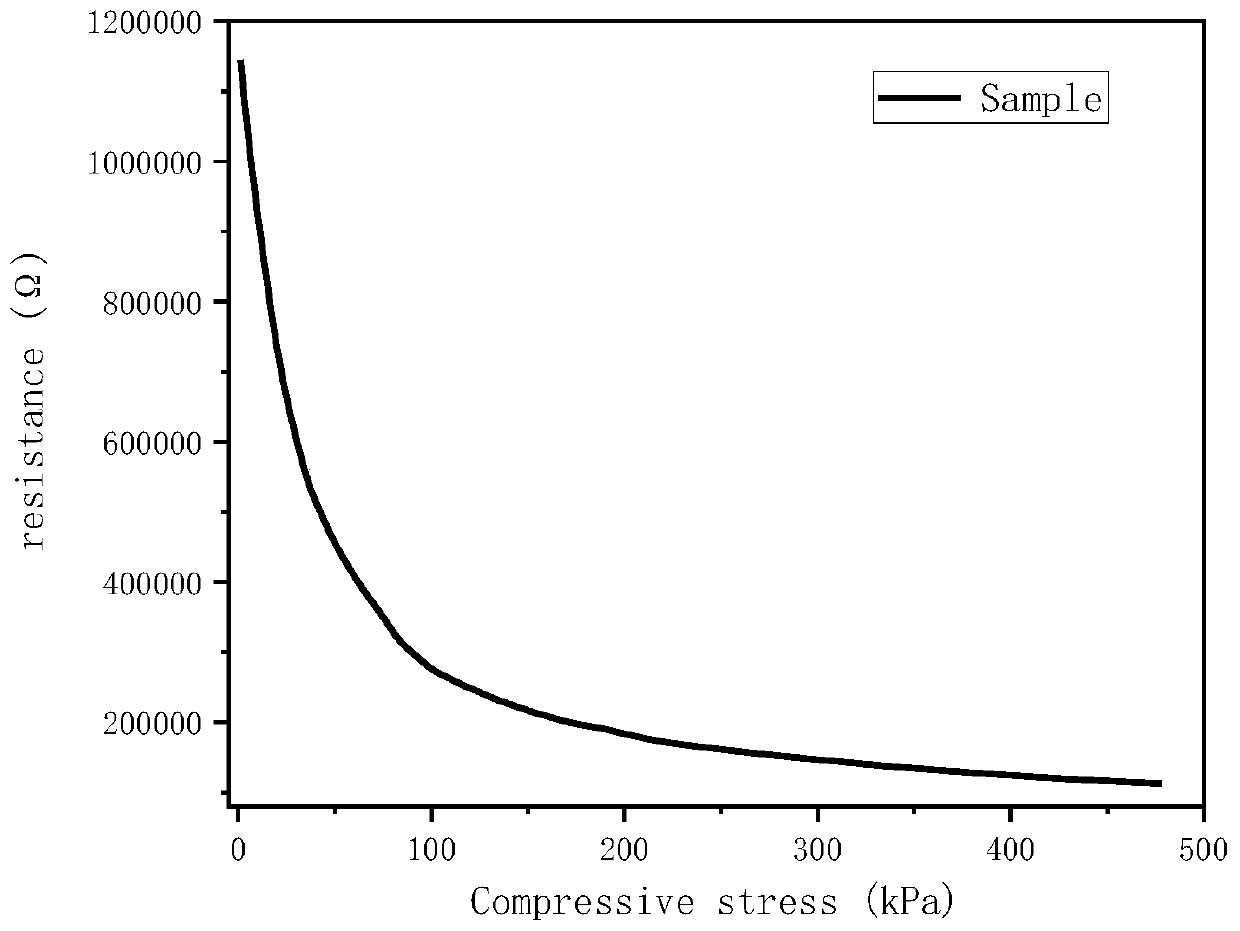

[0050] It can be seen from the results in the above table that the diameter of the elastic conductive rope core in the linear sensing material affects the breaking strength and sensing performance of the obtained coated linear sensing material. It can be known from the data in the comprehensive table that, under the condition that other conditions remain unchanged, as the diameter of the yarn cord increases, the breaking strength of the obtained full-fiber flexible sensor and its preparation method increases, and the detection range value (detection limit) ...

Embodiment 6-9

[0052] Embodiments 6-9 provide a full-fiber-based flexible sensor. Compared with Example 1, the difference is that the diameter of the conductive yarn in the full-fiber-based flexible sensor is changed, and other operations are the same, and will not be repeated here. For details, the specific experimental conditions, parameters and performance test results are shown in the table below.

[0053]

[0054]

[0055] It can be seen from the results in the above table that the diameter of the conductive yarn in the linear sensing material directly affects the breaking strength and sensing performance of the obtained coated linear sensing material. Based on the data in the table, it can be seen that under the condition of other conditions unchanged, as the diameter of the conductive yarn increases, the breaking strength of the all-fiber flexible sensor increases, the detection range value (detection limit) increases, and the sensitivity increases with the increase of the conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com