High-conduction-stability superelastic yarn, and preparation method and application thereof

An elastic yarn and stability technology, applied in the field of new electronic materials, can solve the problems of high price of conductive polymers, yarn stretchability, low conductivity and conductive stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, SBS is used as the elastomer fiber substrate, dichloroethane is used as the solvent, and gallium indium alloy (Ga 0.685 In 0.215 sn 0.1 , melting point -19°C) as a conductive material, the present invention will be further described through examples, but this should not limit the scope of protection of this patent, all other thermoplastic elastomer materials that can be used for spinning, all soluble thermoplastic elastomers Solvents and liquid metals with a melting point lower than room temperature are suitable for the superelastic yarn with high electrical conductivity and high electrical conductivity stability and the preparation method disclosed in the present invention.

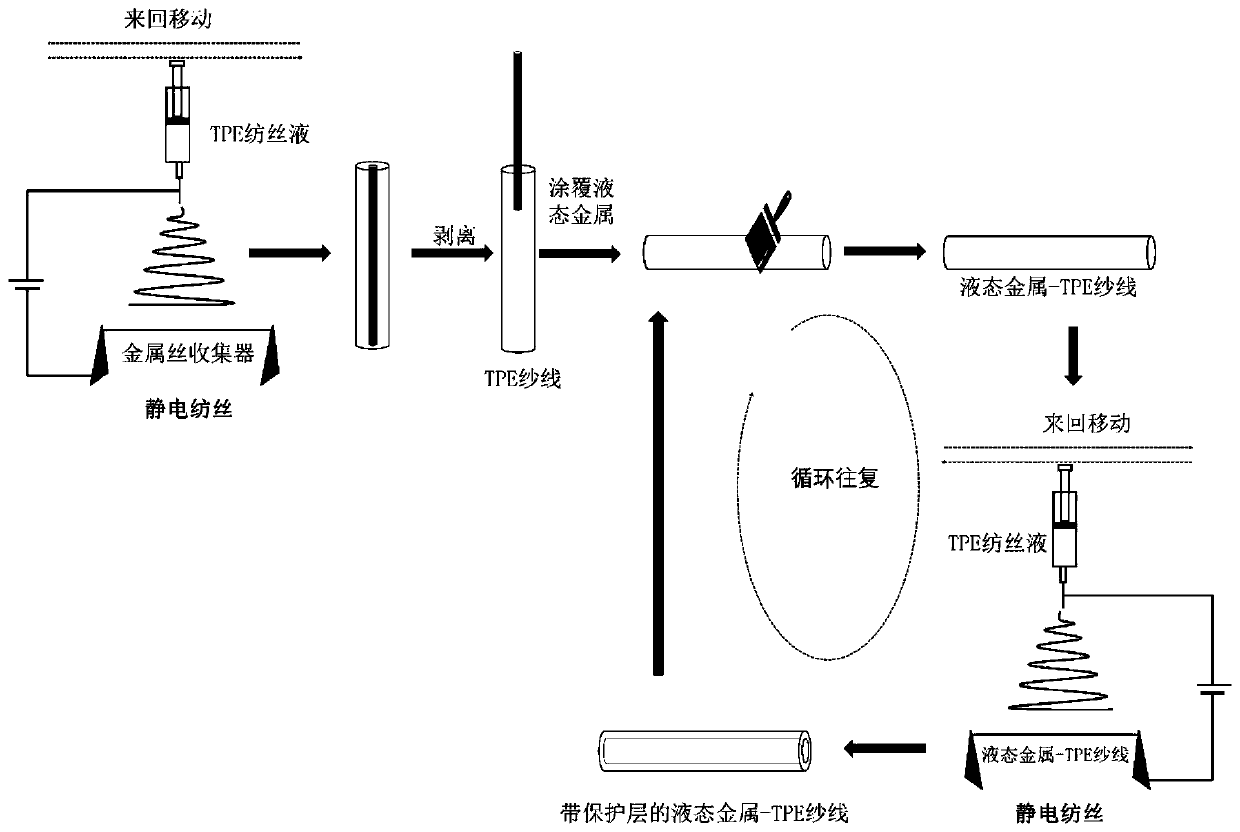

[0036] The present embodiment provides a kind of preparation method of high conductive stability superelastic yarn, comprises the following steps:

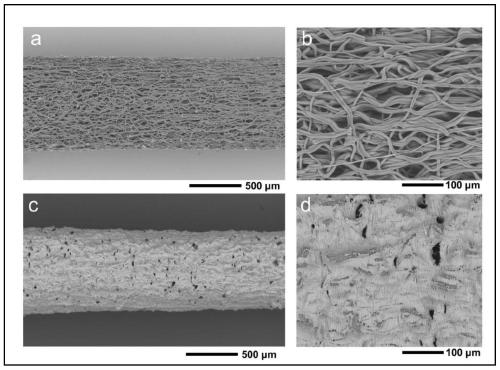

[0037] (1) Preparation of spinning solution: dissolving the thermoplastic elastomer material TPE in an organic solvent to obtai...

Embodiment 2

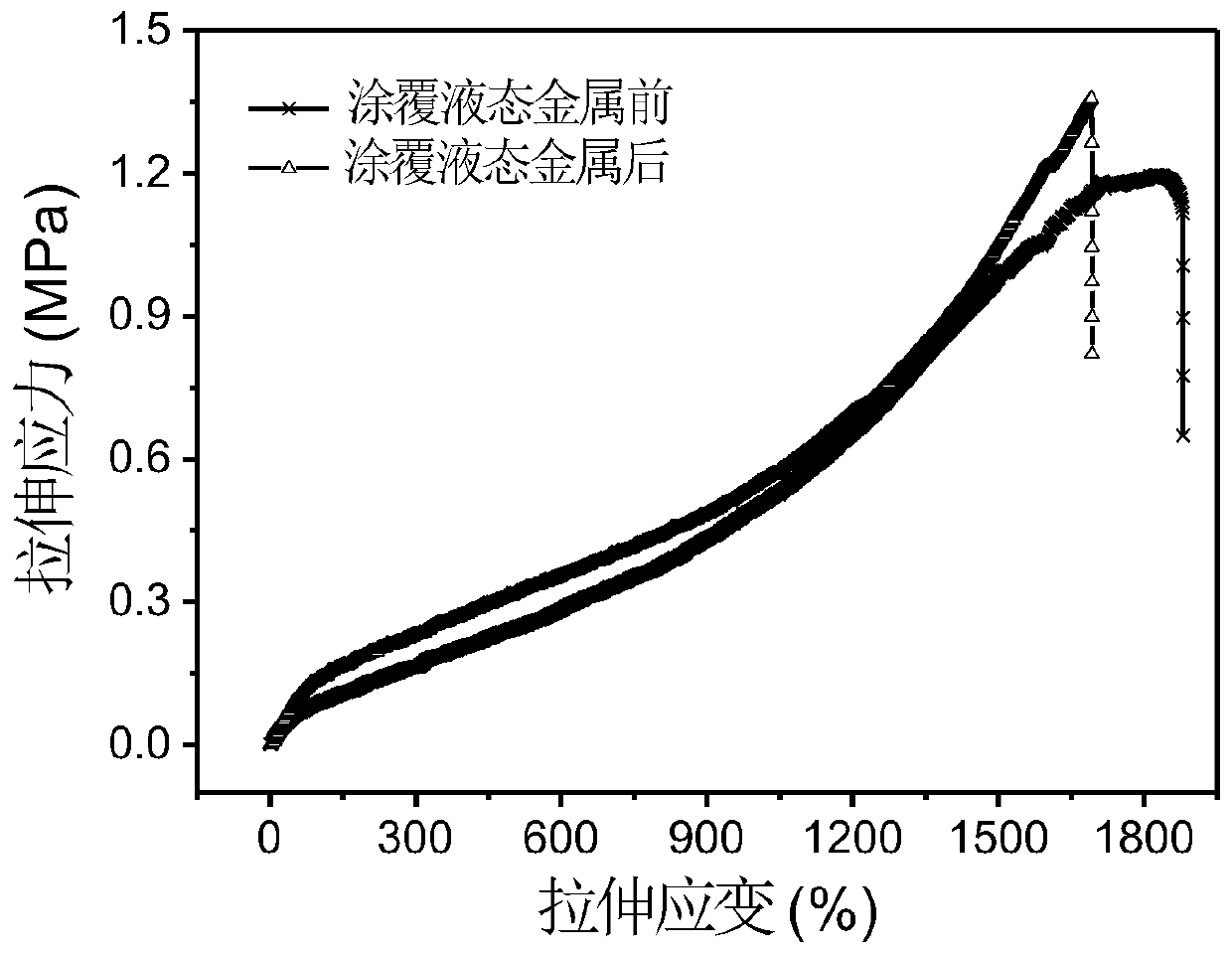

[0051] This embodiment provides a high conductive stability superelastic yarn and a preparation method thereof. The preparation steps are the same as the preparation steps provided in Example 1. The difference is that the surface of the elastic conductive yarn obtained in step (4) is A layer of TPE fiber is coated by electrospinning again to form a coating or protective layer, which changes the type of TPE or liquid metal, as shown in Table 1:

[0052] The elastic conductive yarn provided in Example 2 of Table 1.

[0053]

[0054]

[0055]

[0056]

[0057] The operation of applying liquid metal must be carried out at a temperature higher than the melting point of the liquid metal used. For example the liquid metal used is Ga 0.685 In 0.215 sn 0.1 , the operating ambient temperature must be higher than -19°C; the liquid metal used is Ga 0.67 In 0.29 Zn 0.04, the operating ambient temperature must be higher than 13°C; the liquid metal used is Ga 092 sn 0.08 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com