Waterproof conductive yarn

A technology of conductive yarn and conductive layer, which is applied in the direction of yarn, textiles and papermaking, etc., can solve the problems of poor elongation of conductive yarn, broken conductive yarn, broken conductive yarn, etc., and achieves convenient production methods and improved weavable performance, improve the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

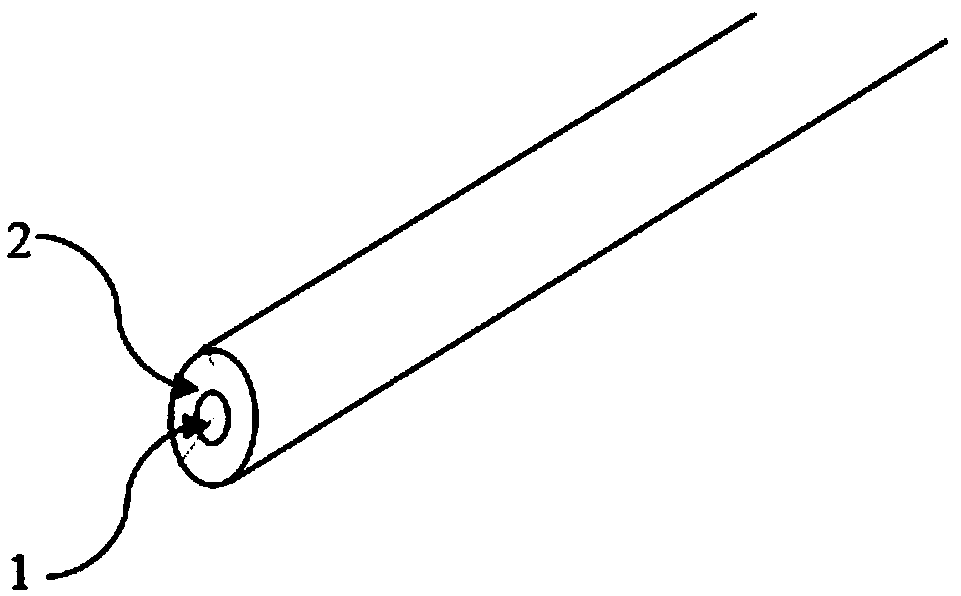

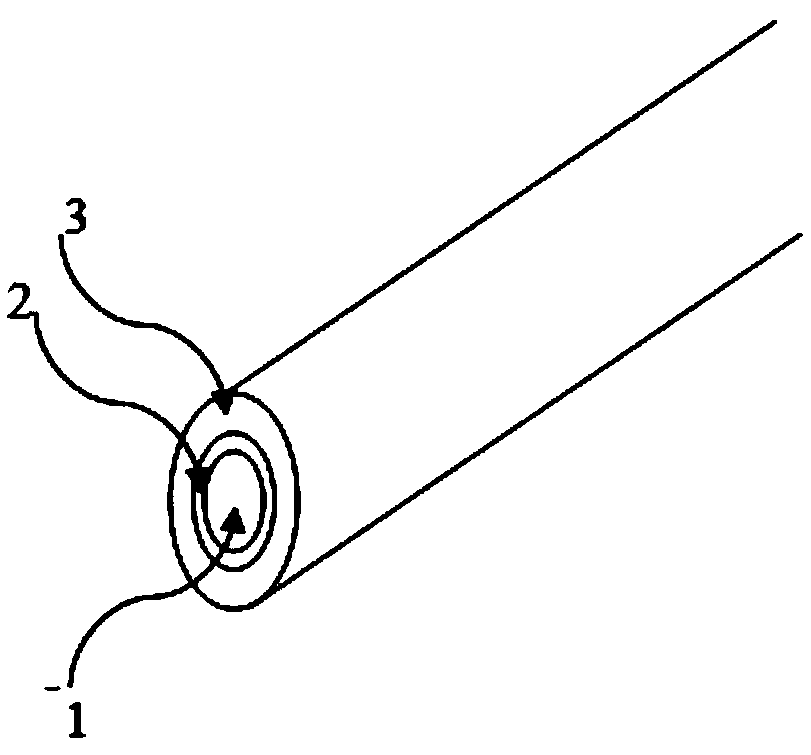

[0028] Such as figure 2 In the waterproof conductive yarn structure shown, the conductive yarn is a three-layer structure, which is a conductive layer 1, a waterproof layer 2 and a coating layer 3 from the inside to the outside; wherein the conductive layer 1 provides conductivity for the conductive yarn; Such as figure 1 As shown, the waterproof layer 2 is coated on the outer layer of the conductive layer 1, and the waterproof layer 2 is an elastic waterproof polymer material layer, which provides waterproof performance and physical strength for the conductive yarn; the coating layer 3 is wrapped on the outer layer of the waterproof layer 2, wrapping The cladding layer 3 is a fiber layer, which provides insulation for the conductive yarn and prevents the waterproof layer 2 from being damaged during weaving and use.

[0029] Wherein, the elastic waterproof polymer material of the waterproof layer 2 can be one of insulating elastomers such as softened rubber, polyurethane, po...

Embodiment 2

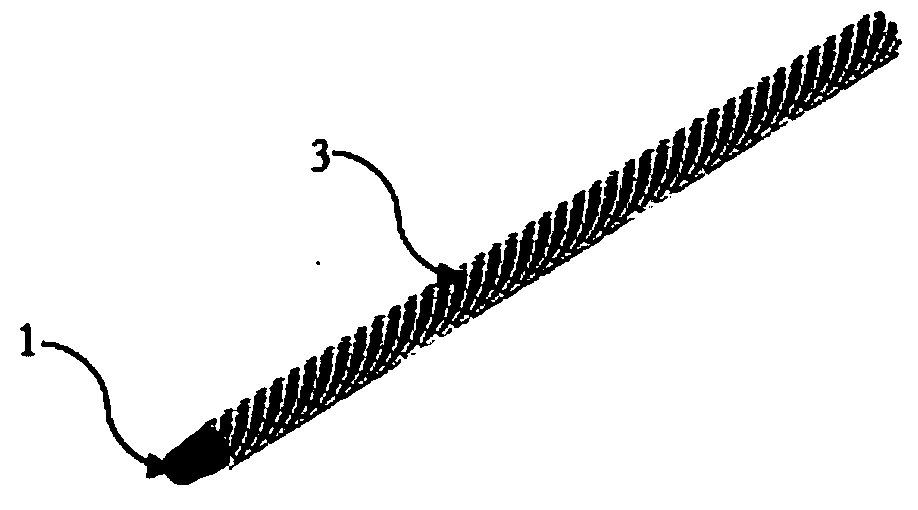

[0034] In the present embodiment 2, the covering layer 3 adopts one layer of braided layer, and the specific structure is as follows: image 3 shown.

[0035] combine figure 1 and image 3 , the conductive yarn has a three-layer structure, which is a conductive layer 1, a waterproof layer 2 and a coating layer 3 from the inside to the outside; wherein the conductive layer 1 provides conductivity for the conductive yarn; as figure 1 As shown, the waterproof layer 2 is coated on the outer layer of the conductive layer 1, and the waterproof layer 2 is an elastic waterproof polymer material layer, which provides waterproof performance and physical strength for the conductive yarn; the coating layer 3 is wrapped on the outer layer of the waterproof layer 2, wrapping The cladding layer 3 is a braided layer, which provides insulation for the conductive yarn and prevents the waterproof layer 2 from being damaged during weaving and use.

[0036] Wherein, the elastic waterproof polym...

Embodiment 3

[0041] In this embodiment 3, conductive layer 1 adopts conductive monofilament 10, and conductive monofilament 10 is as Figure 4 shown. The conductive monofilament 10 can be metal, and the metal filament monofilament can be obtained by drawing a long metal strip, or the conductive filament can be made of metal, carbon or conductive polymer by means of doping or coating.

[0042] combine figure 1 and figure 2 or figure 1 and image 3 , the waterproof conductive yarn structure of the present embodiment 3 is: conductive monofilament 10 is coated with waterproof layer 2 outside, increases the waterproof performance of conductive monofilament 10, and waterproof layer 2 wraps cladding layer 3 outside, prevents waterproof layer 2 from weaving and damage during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com