Elastic array pressure sensor

A pressure sensor and array technology, applied in the field of sensors, can solve the problems of conductive cloth conductive fiber resistance change, conductive fiber breakage, flexible substrate detachment, etc., to achieve the same conductive length, stable resistance value, and pressure detection. value-accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Such as Figure 3-6 Shown, described elastic conductive yarn 100, its preparation method, comprises the following steps:

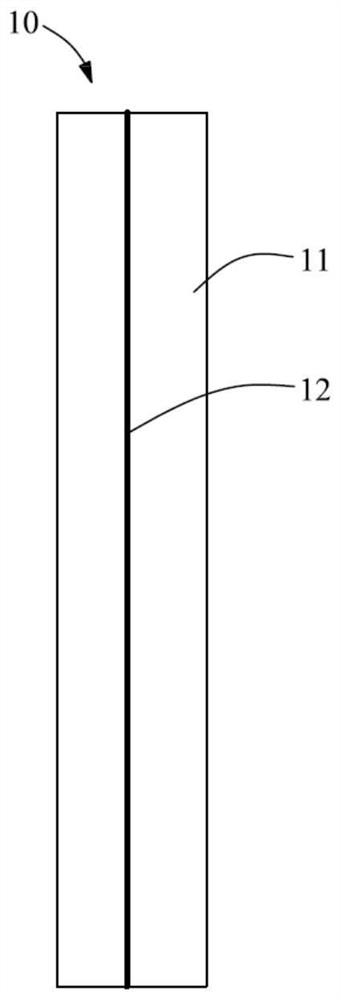

[0041] S1, firstly, the conductive core-spun yarn 10 is prepared by ring spinning; on the ring spinning machine, a predetermined amount of fiber roving 11 is fed from the bell mouth (not shown), and the fiber roving is obtained after being drafted by the drafting device 30. The fiber strands are pressed by the first front roller opening composed of the front bottom roller 31 and the front top roller 32 of the drafting device 30; at the same time, the conductive fiber filament 12 passes through the first tension disc 121 and the first godet roller 122. , fed from the mouth of the first front roller;

[0042]The fiber roving 11 is twisted and wrapped around the conductive fiber filament 12 to form a conductive core-spun yarn 10 (such as image 3 shown); like this, the core yarn of the conductive core-spun yarn 10 is a conductive fiber filament 12, a...

Embodiment 1

[0061] Described fiber roving 11 adopts polyester roving, and described conductive fiber filament 12 adopts silver-plated nylon filament; Described elastic fiber filament 20 adopts spandex, wherein, the fiber quantitative ratio of described fiber roving 11 and conductive fiber filament 12 The ratio is 1:7; the fineness of the conductive fiber filament 12 is 40D; the fineness of the elastic fiber filament 20 is 50D.

[0062] 1) On the ring spinning frame, the polyester roving with a dry basis weight of 6g / 10M is fed from the bell mouth, the total draft multiple of the drafting device 30 is 13.39, and the draft multiple of the rear draft zone is 1.6. The conductive fiber filament 12 passes through the first tension disc 121 and the first godet roller 122 in sequence, and the feeding pretension of the conductive fiber filament 12 is 10g;

[0063] The fiber roving 11 is twisted and wrapped with the conductive fiber filament 12S to form the conductive core-spun yarn 10, and its twi...

Embodiment 2

[0069] The difference from Example 1 is that: the fiber roving 11 and the conductive fiber filament 12S are twisted and twisted to form the conductive core-spun yarn 10, and its twist coefficient is 380; the elastic fiber filament 20 and the conductive The elastic conductive yarn 100 prepared from the core-spun yarn 10 has a twist coefficient of 380.

[0070] The experimental results are as follows:

[0071] Stretch length (cm) 20 21 22 23 24 25 26 27 Measured resistance value (Ω) 783 789 792 795 801 808 815 822

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com