Patents

Literature

35 results about "Textile sensors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

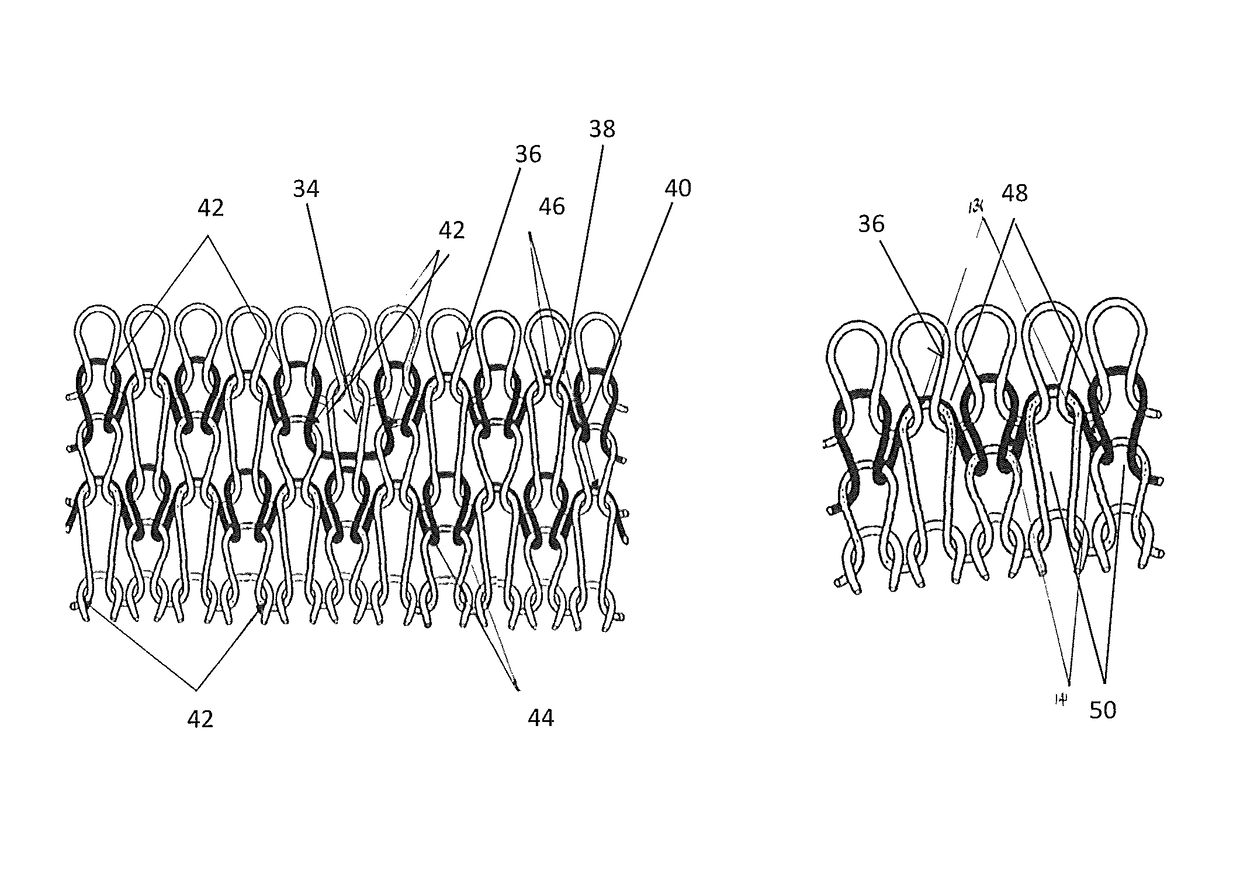

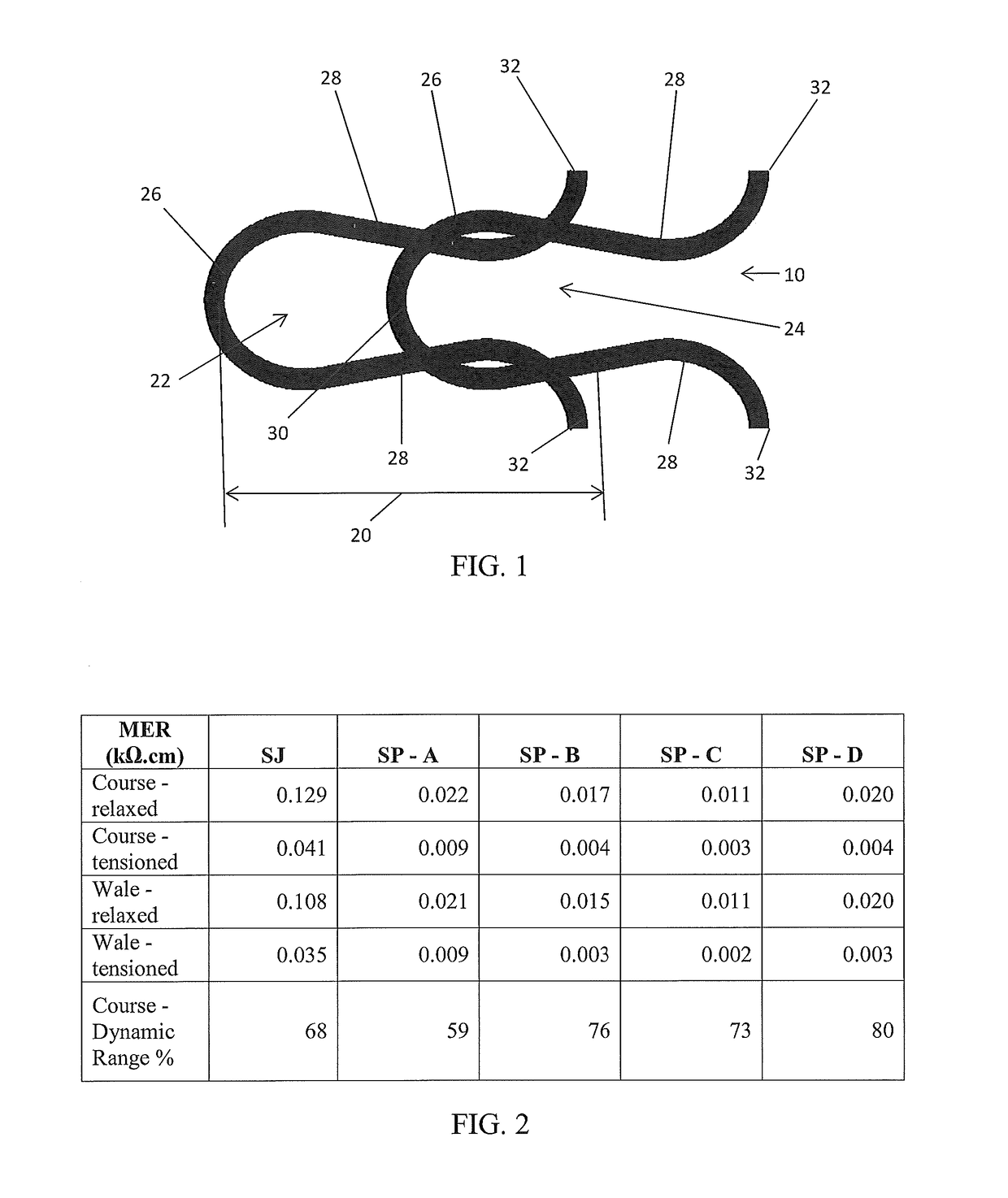

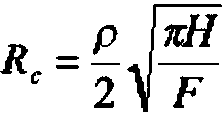

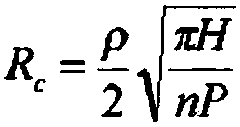

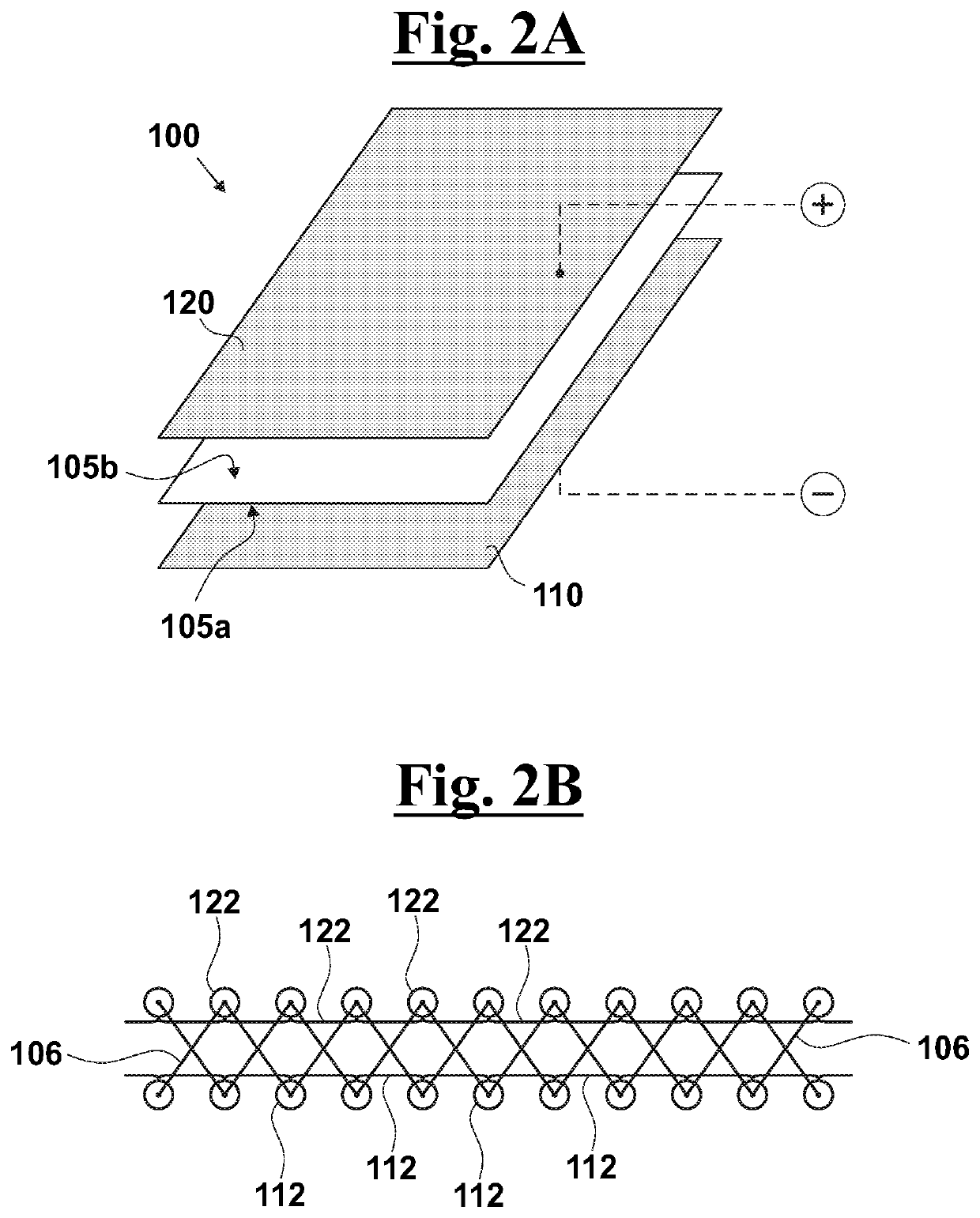

Method for making electrically conductive textiles and textile sensor

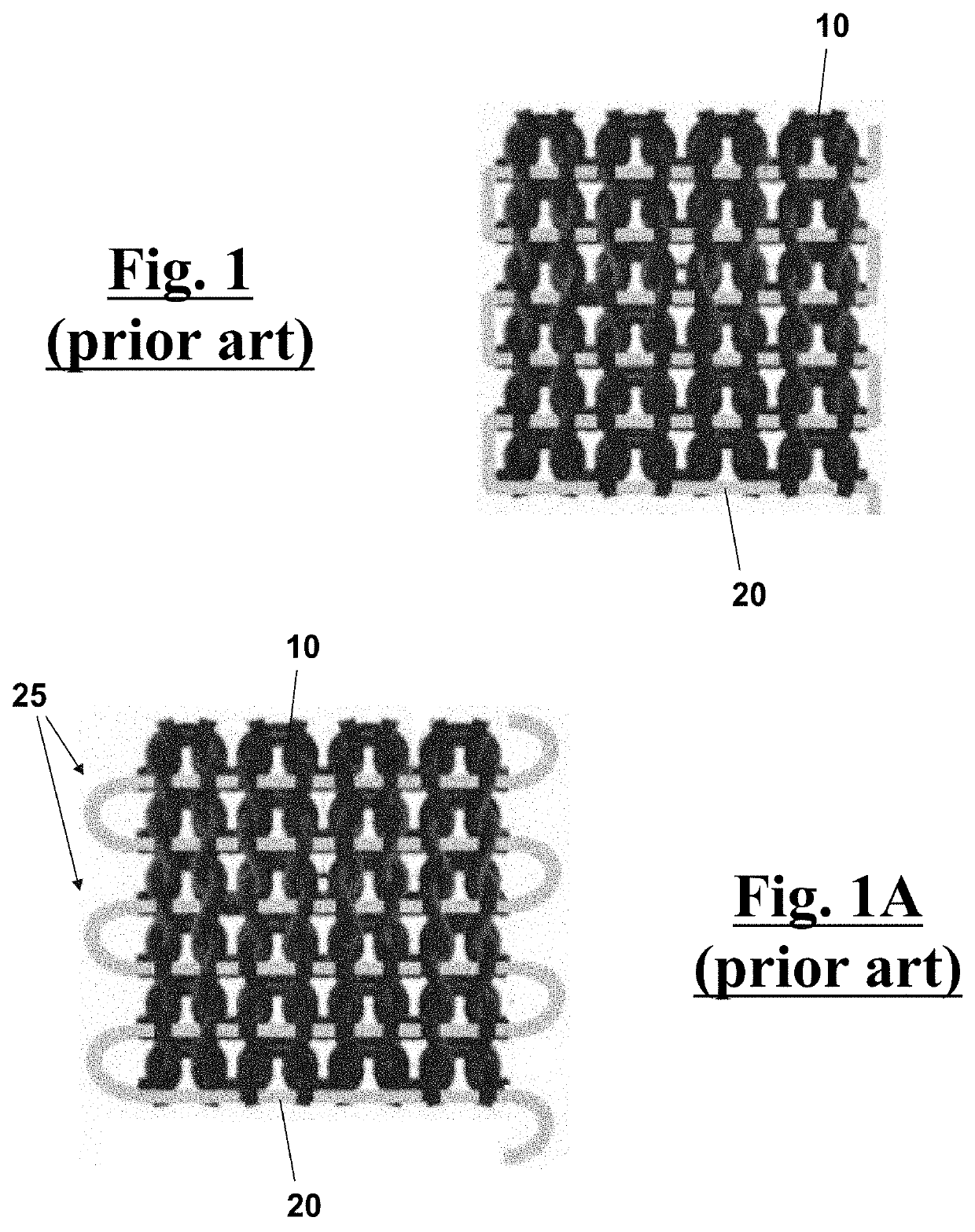

ActiveUS20160186366A1Automatically calibratingIncrease contact resistanceCrochetingOrnamental textile articlesYarnElectrical resistance and conductance

A method for making a textile sensor and a textile sensor can include selecting a combination of variables from the group consisting of yarn variables, stitch variables, and textile variables; and knitting an electrically conductive yarn in the textile sensor in accordance with the selected combination of variables, wherein the combination of variables is selected so as to provide a controlled amount of contact resistance in the textile sensor. The method and textile can further include a capacitive textile-sensor having at least two integrally knit capacitor plate elements and having a configuration adapted for a sensing activity. Resistance in the textile sensor can automatically calibrate to a stable baseline level after the textile sensor is applied to a body.

Owner:FOOTFALLS & HEARTBEATS (UK) LTD

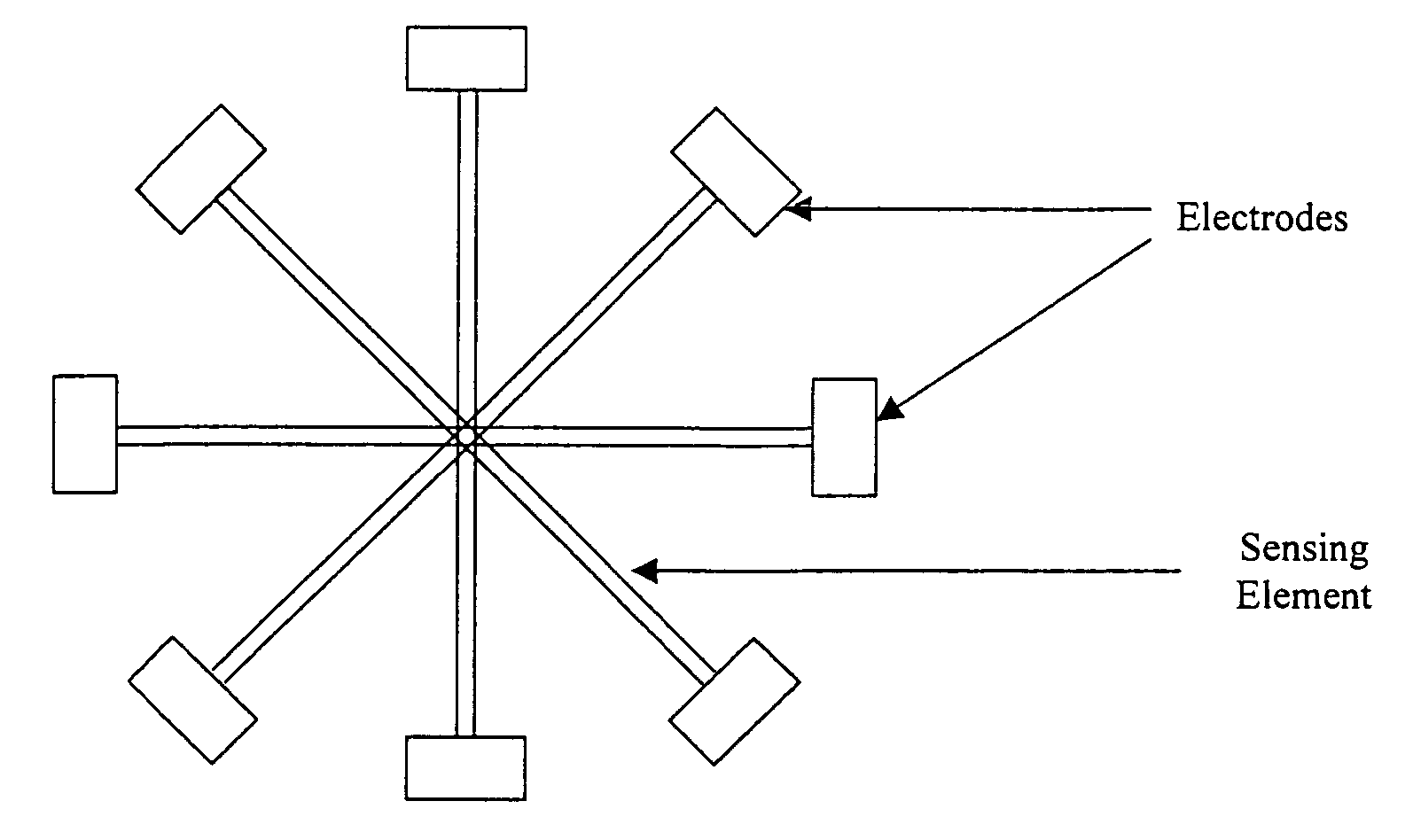

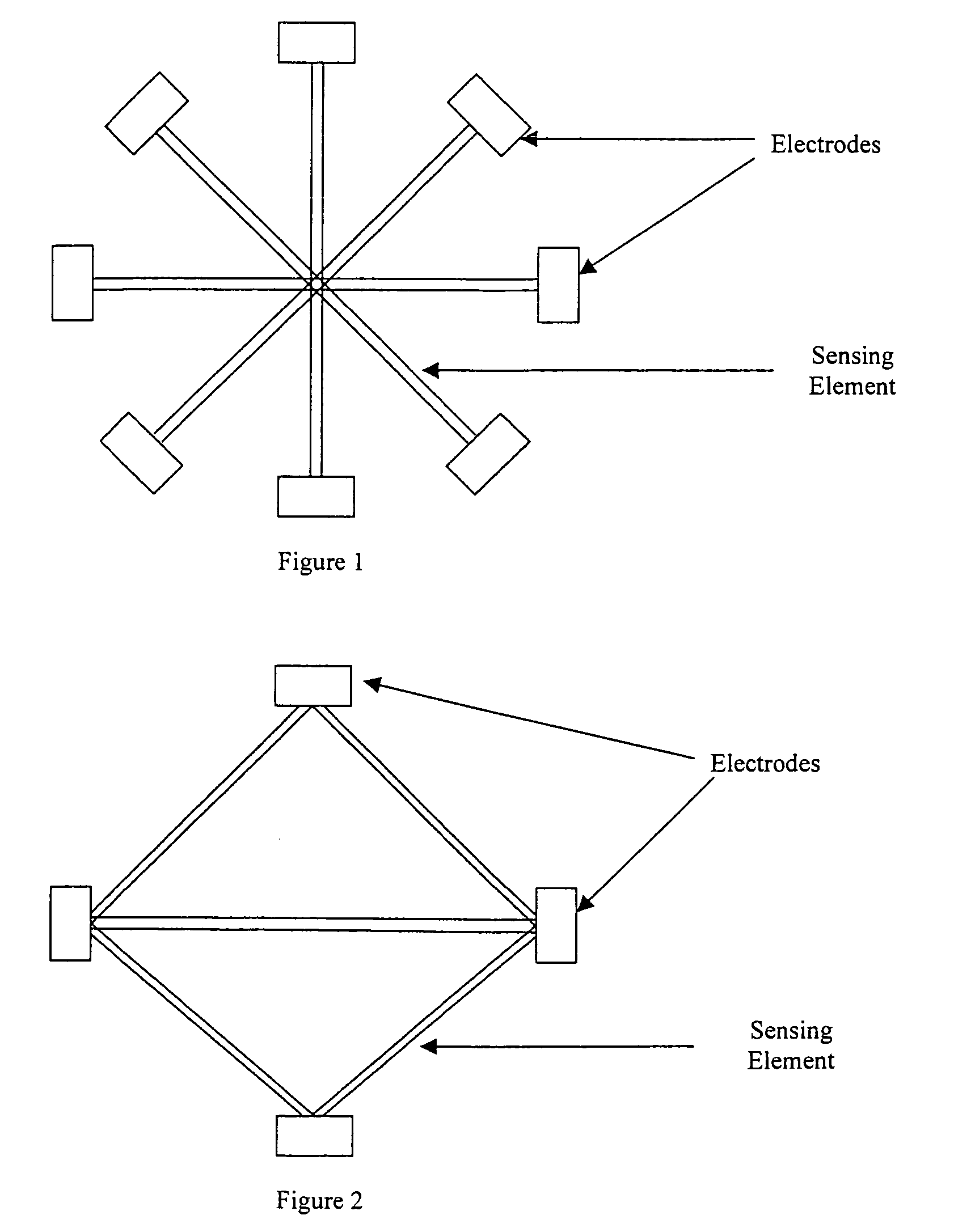

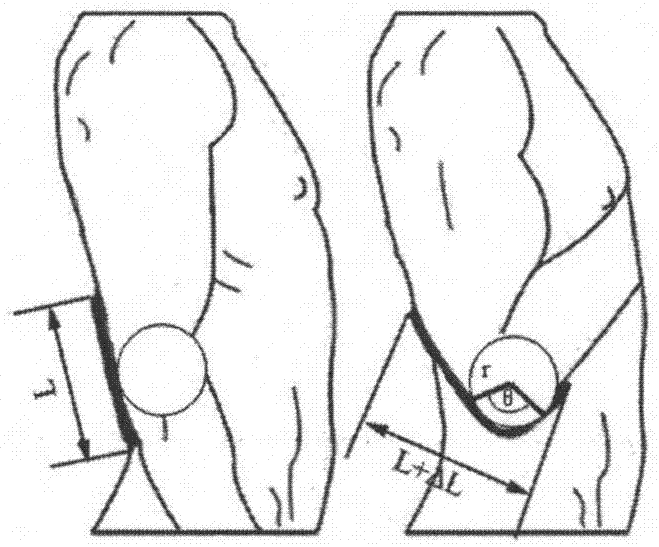

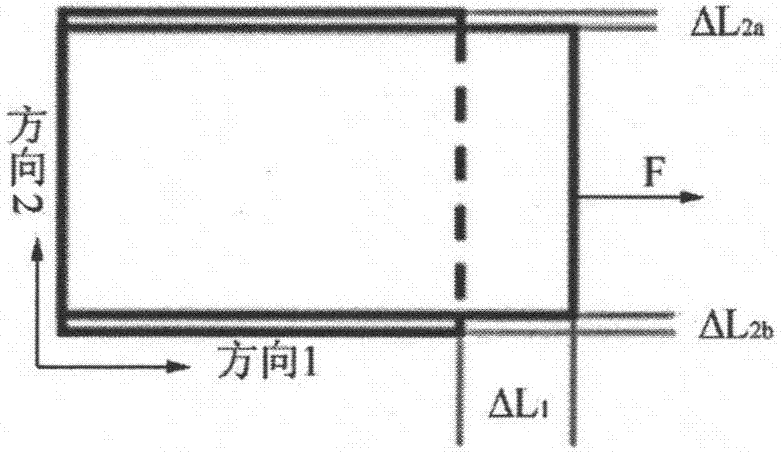

Shear force and pressure measurement in wearable textiles

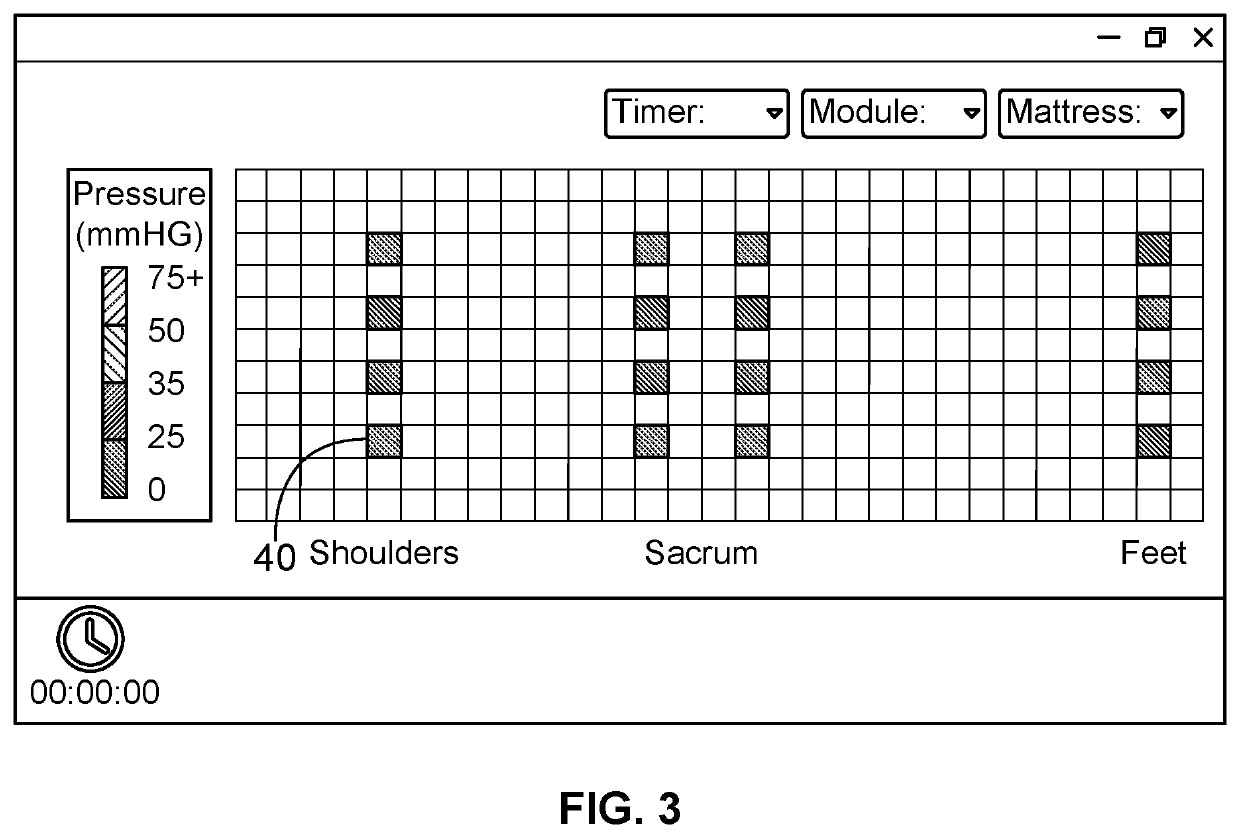

InactiveCN101622518AReduce distanceConstant pressureForce measurementDiagnostic recording/measuringTextile sensorsShear stress

The invention refers to a sensor arrangement comprising at least one capacitance sensor for detecting a pressure and a shear force, wherein the capacitance sensor is integrated into a wearable textile, a method for measuring a shear force and a pressure by such a sensor arrangement, wherein the shear force and pressure is exerted on a skin of a person lying in a bed or sitting in a chair and to combinations and uses of the method. This described textile sensors allow for a simultaneous measurement of shear stress and pressure in anti decubitus textiles. This enhances risk assessment with regard to the development of bedsore ulcer.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

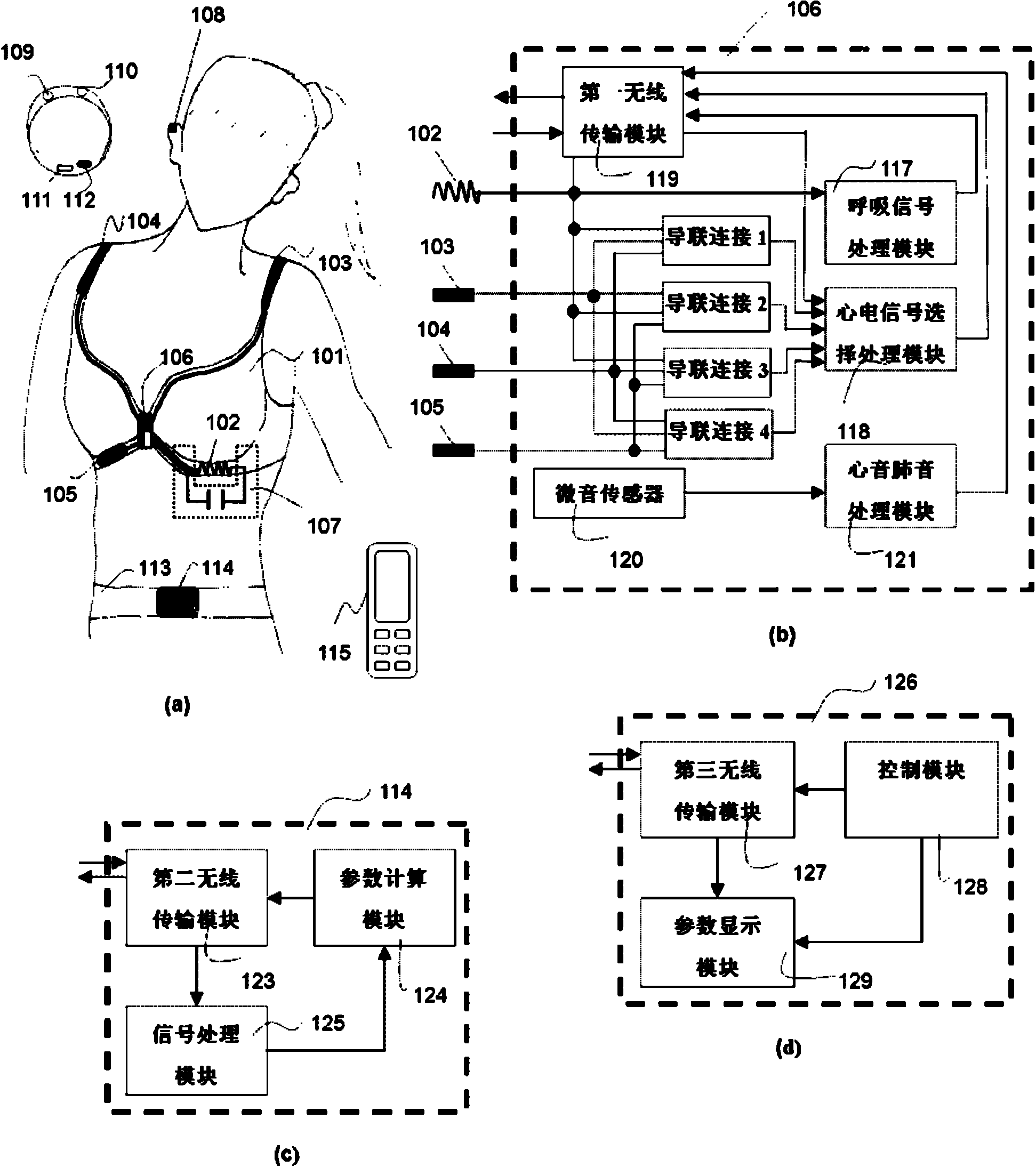

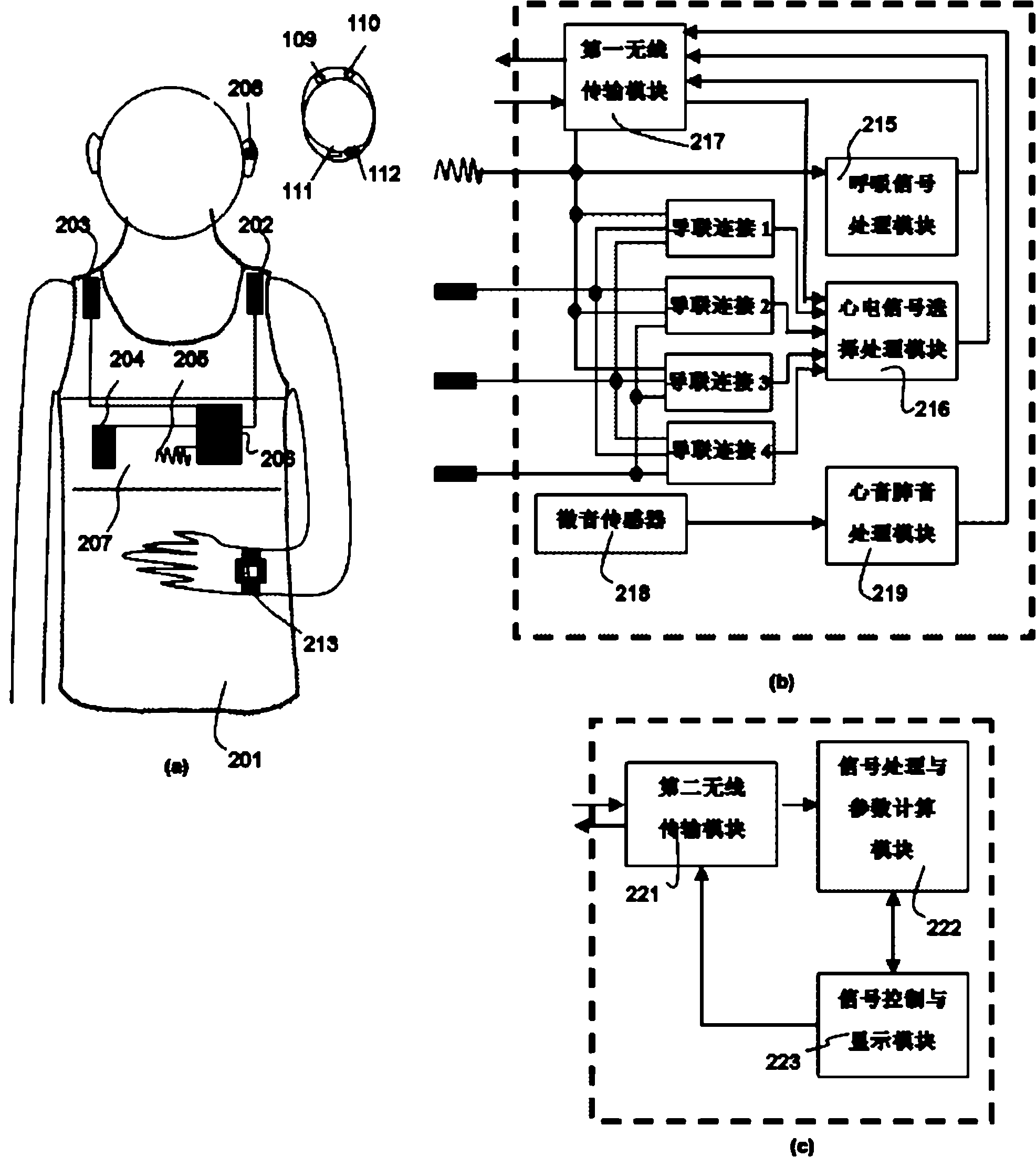

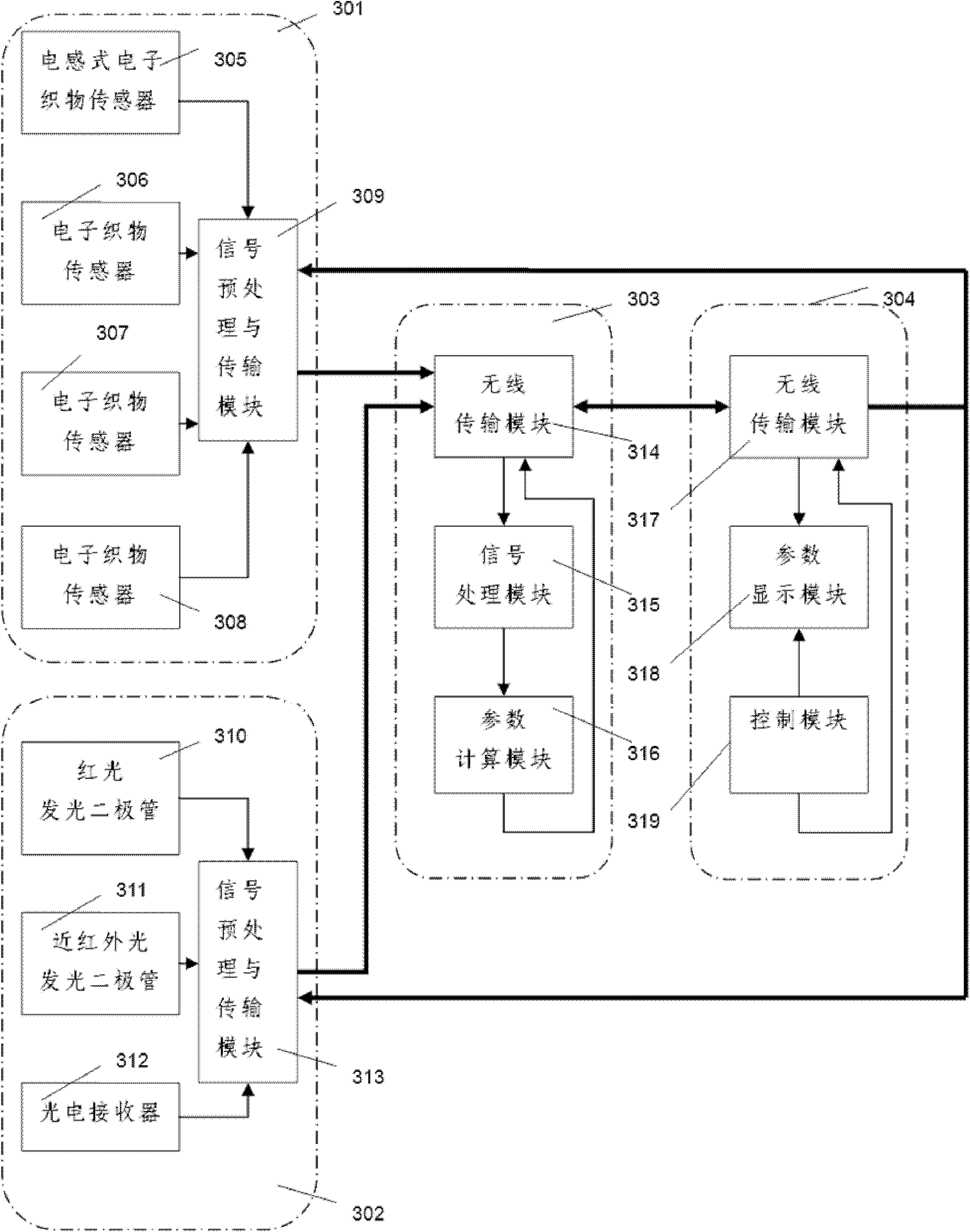

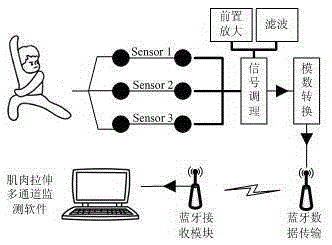

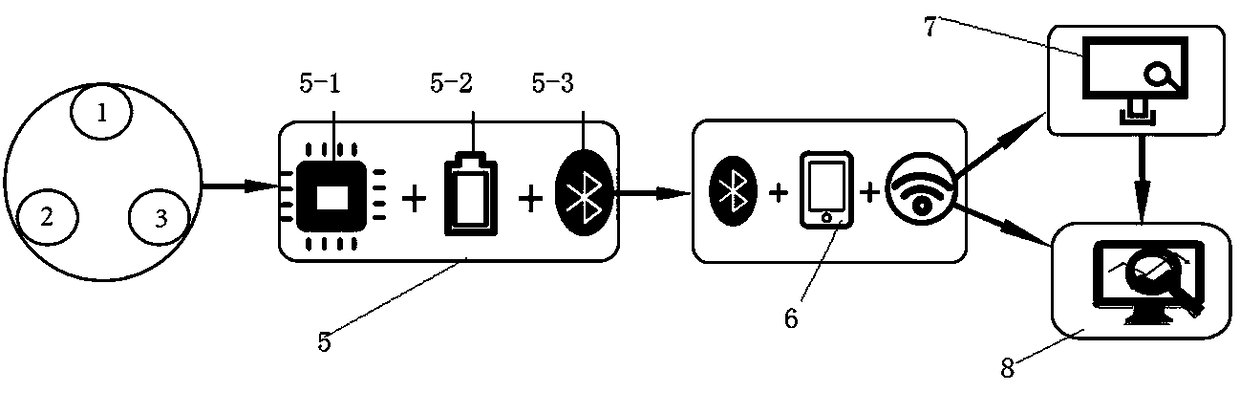

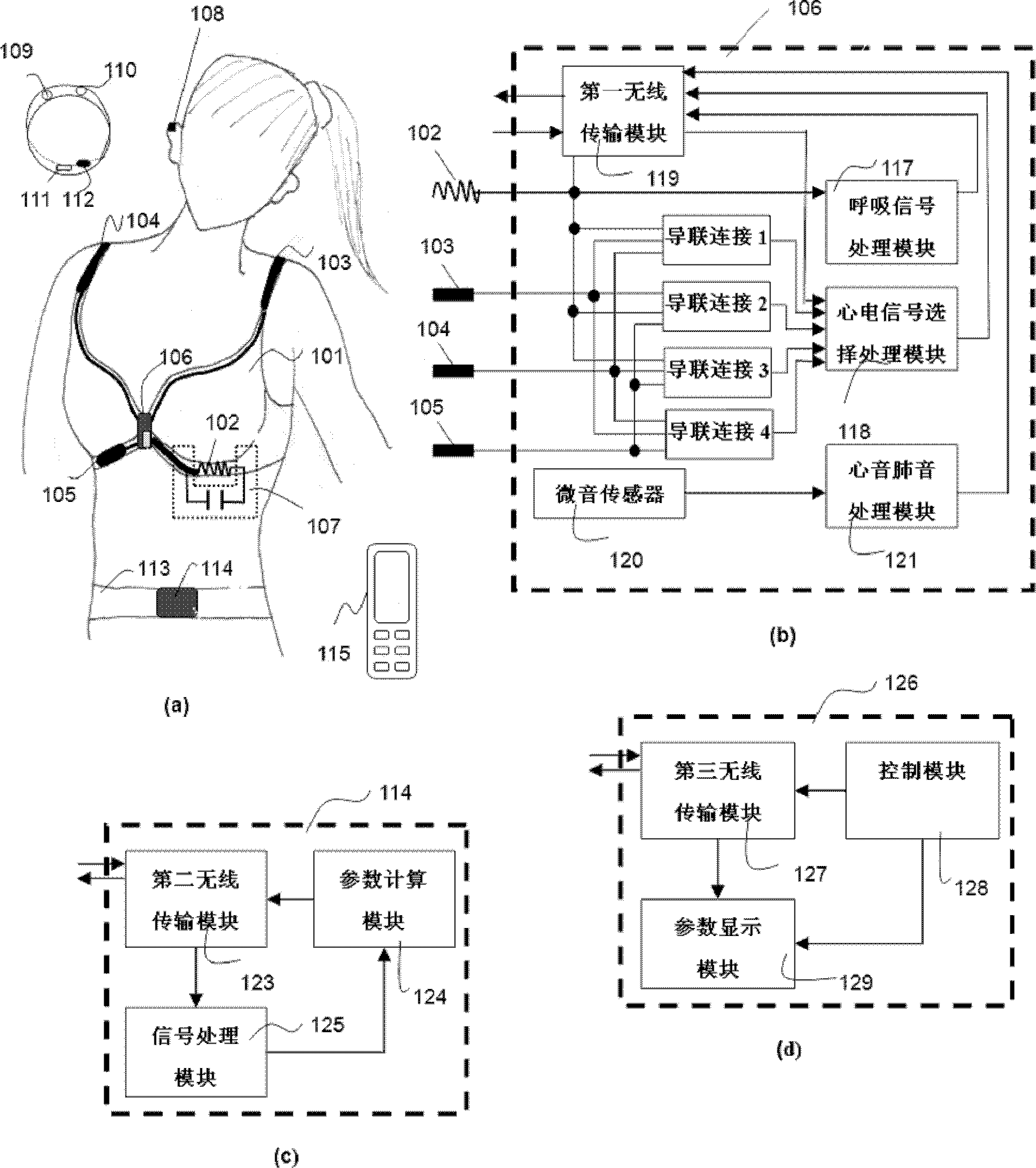

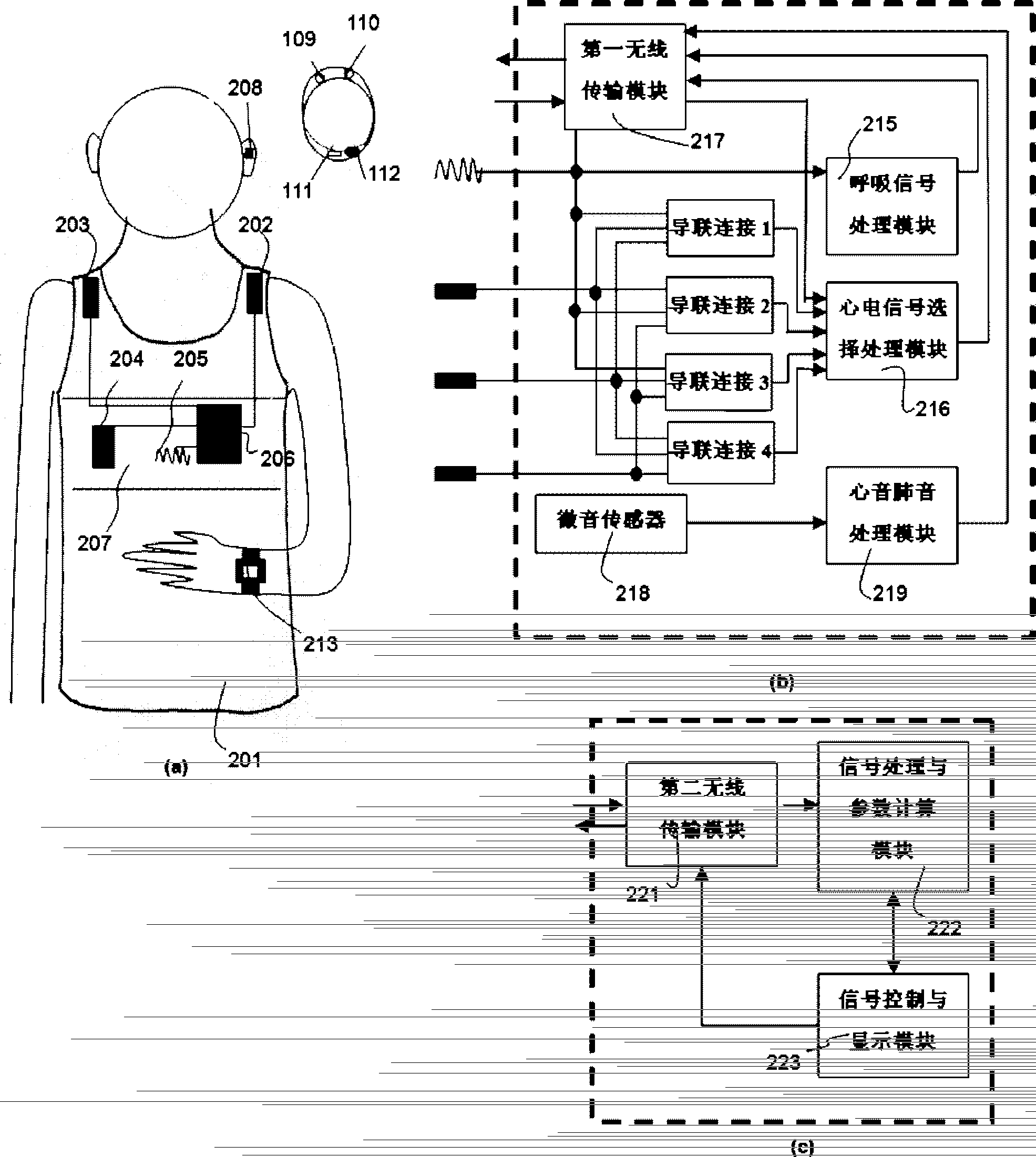

A wearable system that can continuously measure multiple physiological parameters based on body sensory network

ActiveCN102283642AAccurate measurementImprove use comfort performanceEvaluation of blood vesselsAuscultation instrumentsContinuous measurementTextile sensors

The invention relates to a wearable system capable of continuously measuring multiple physiological parameters based on body sensor network. The system comprises at least one physiological signal acquisition module, a signal processing and parameter calculation module, and a signal control and display module, wherein the physiological signal acquisition module is used for acquiring physiological signals; the signal processing and parameter calculation module is used for calculating the physiological parameters according to the physiological signal; the signal control and display module is used for receiving the physiological parameter, displaying the physiological parameter and sending a control signal to control the work of each module; and the sensor adopted by the physiological signal acquisition module is an electronic textile sensor. The physiological parameter measuring system has the advantages of high using comfort and good accuracy.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

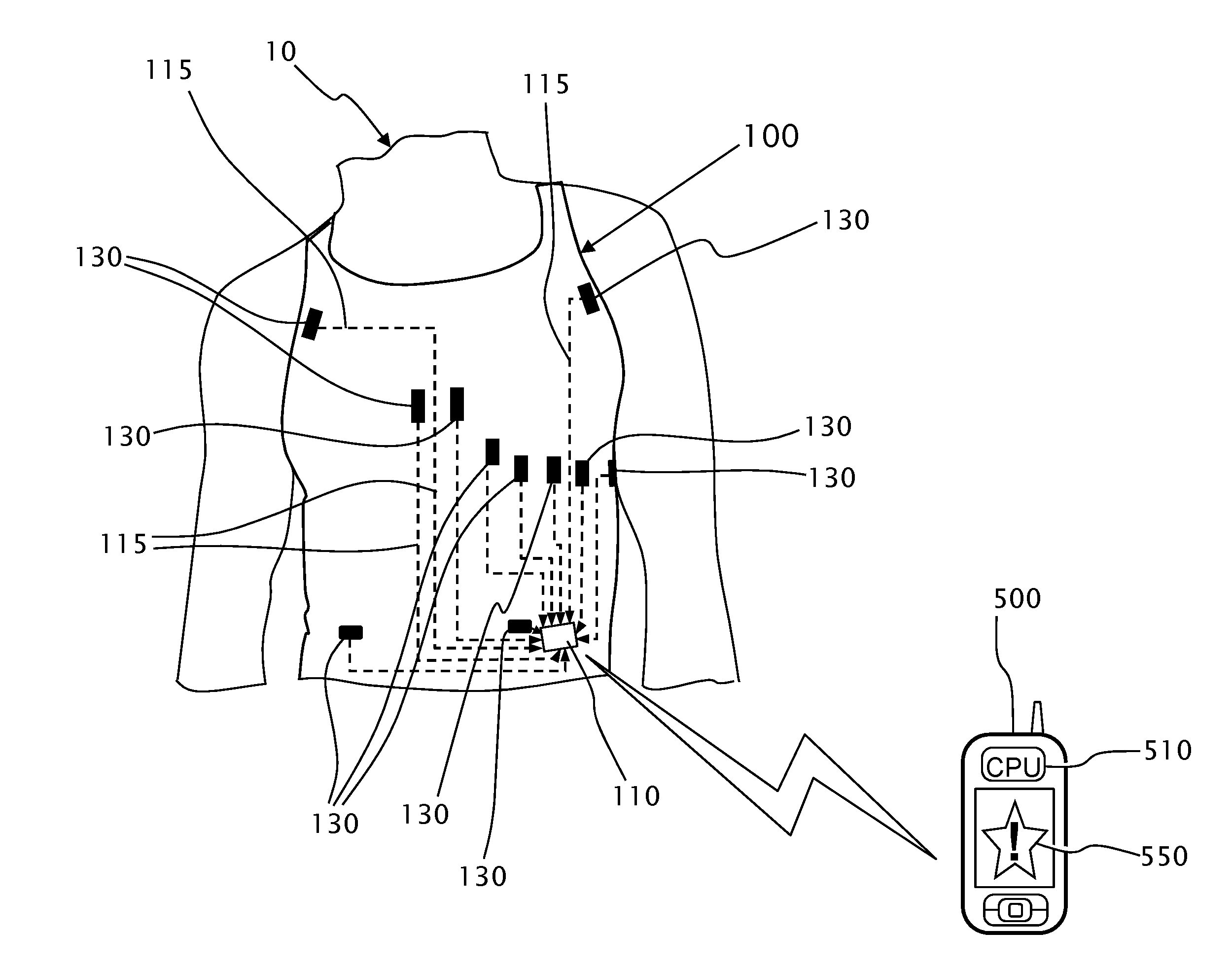

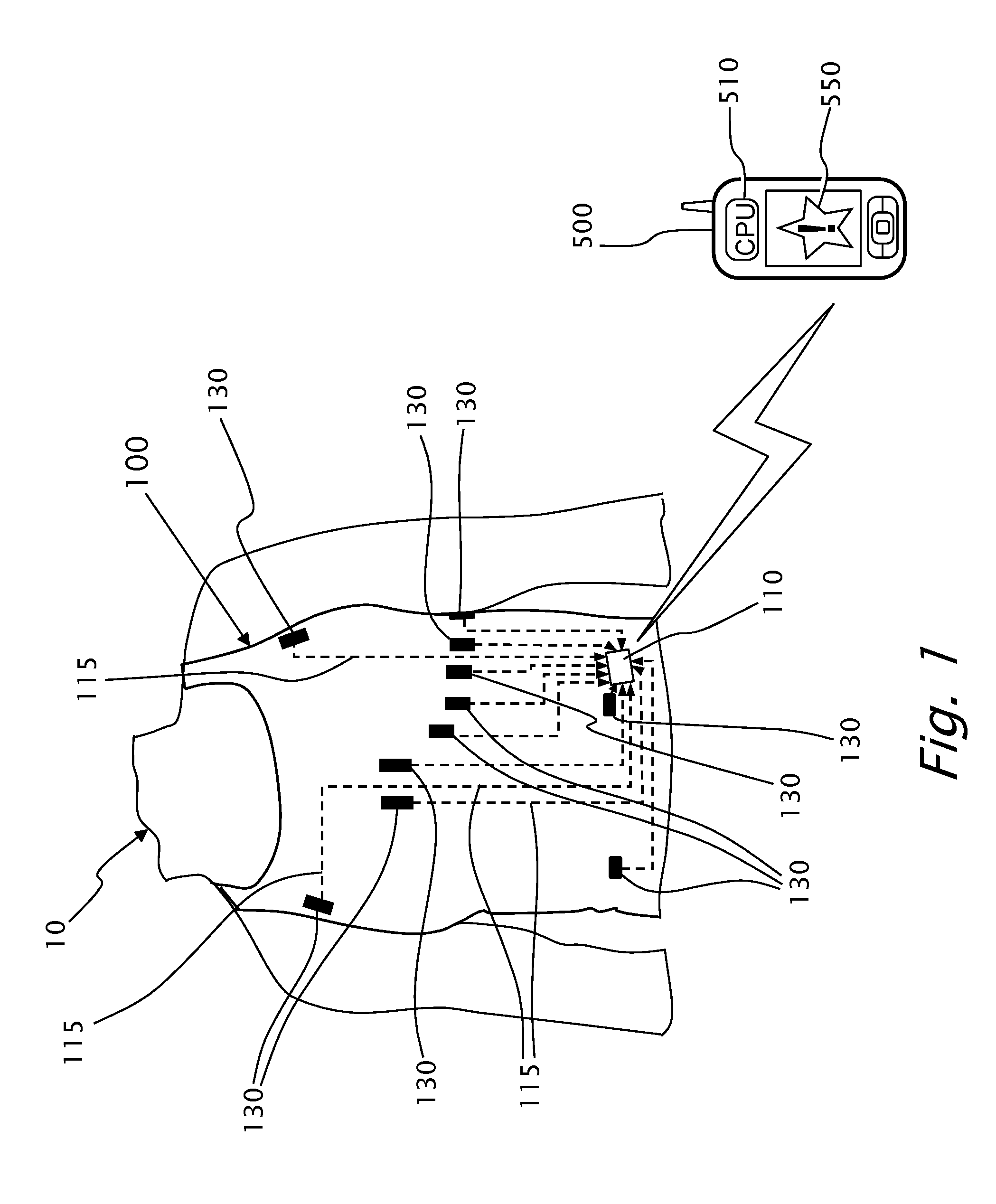

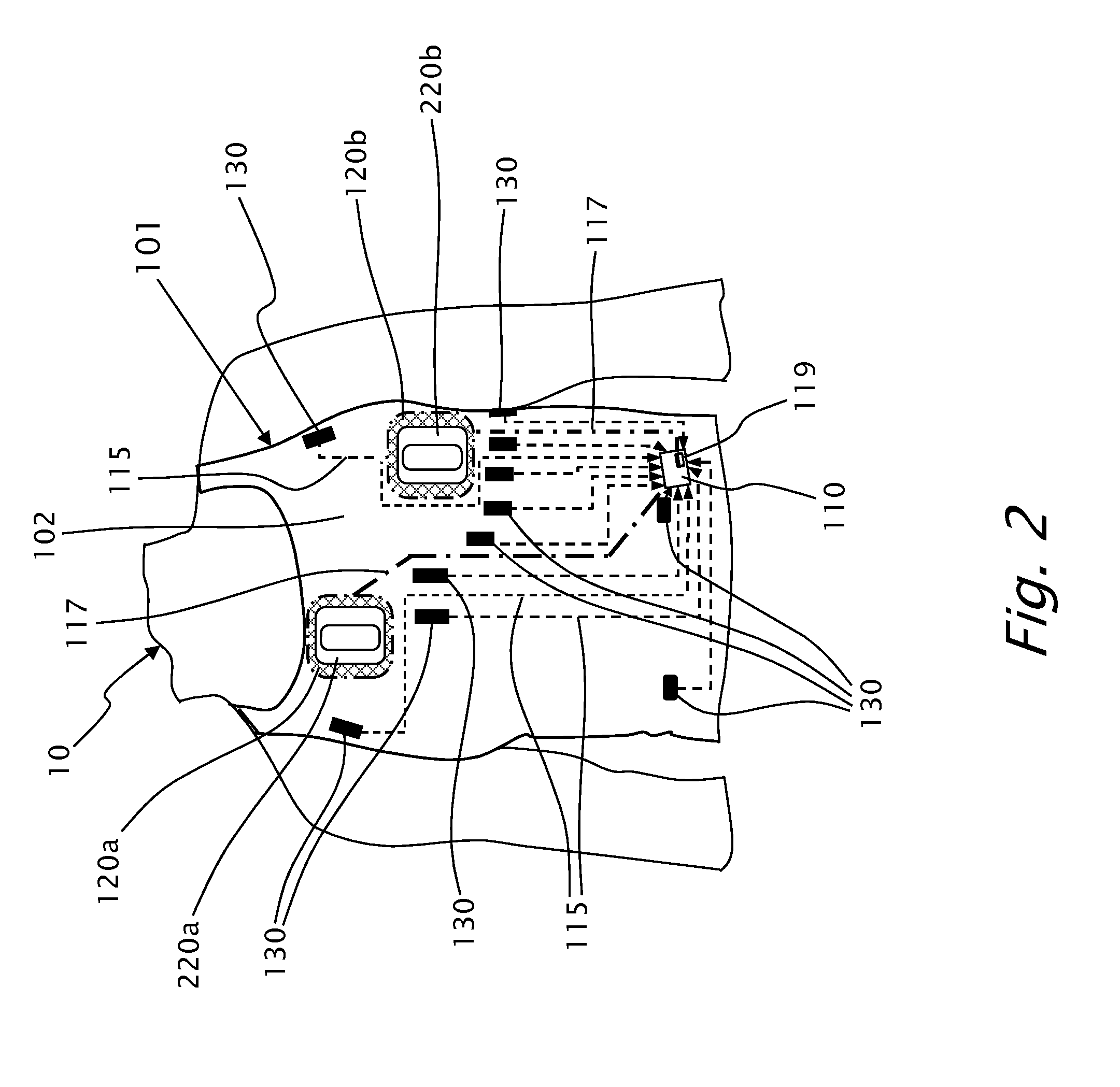

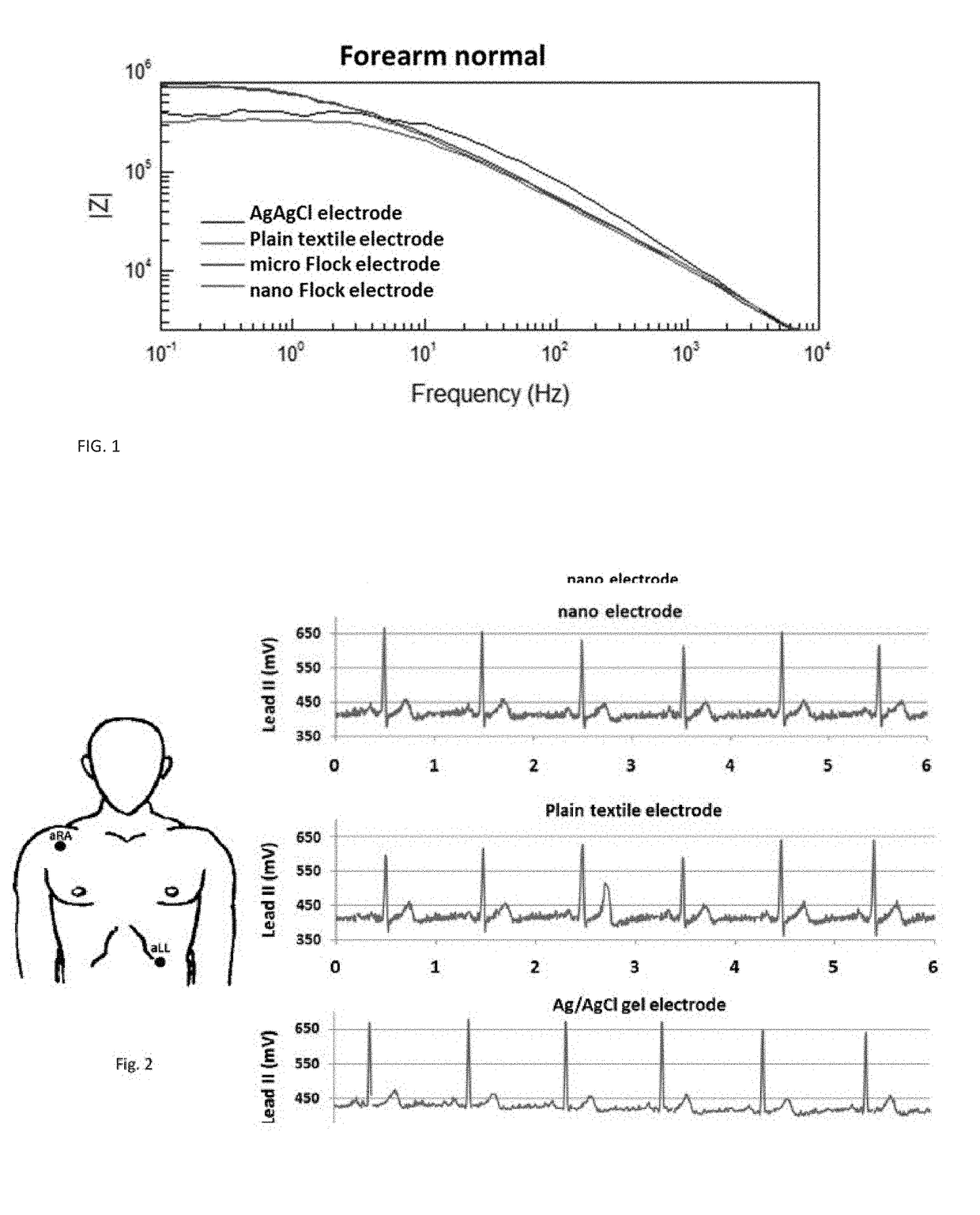

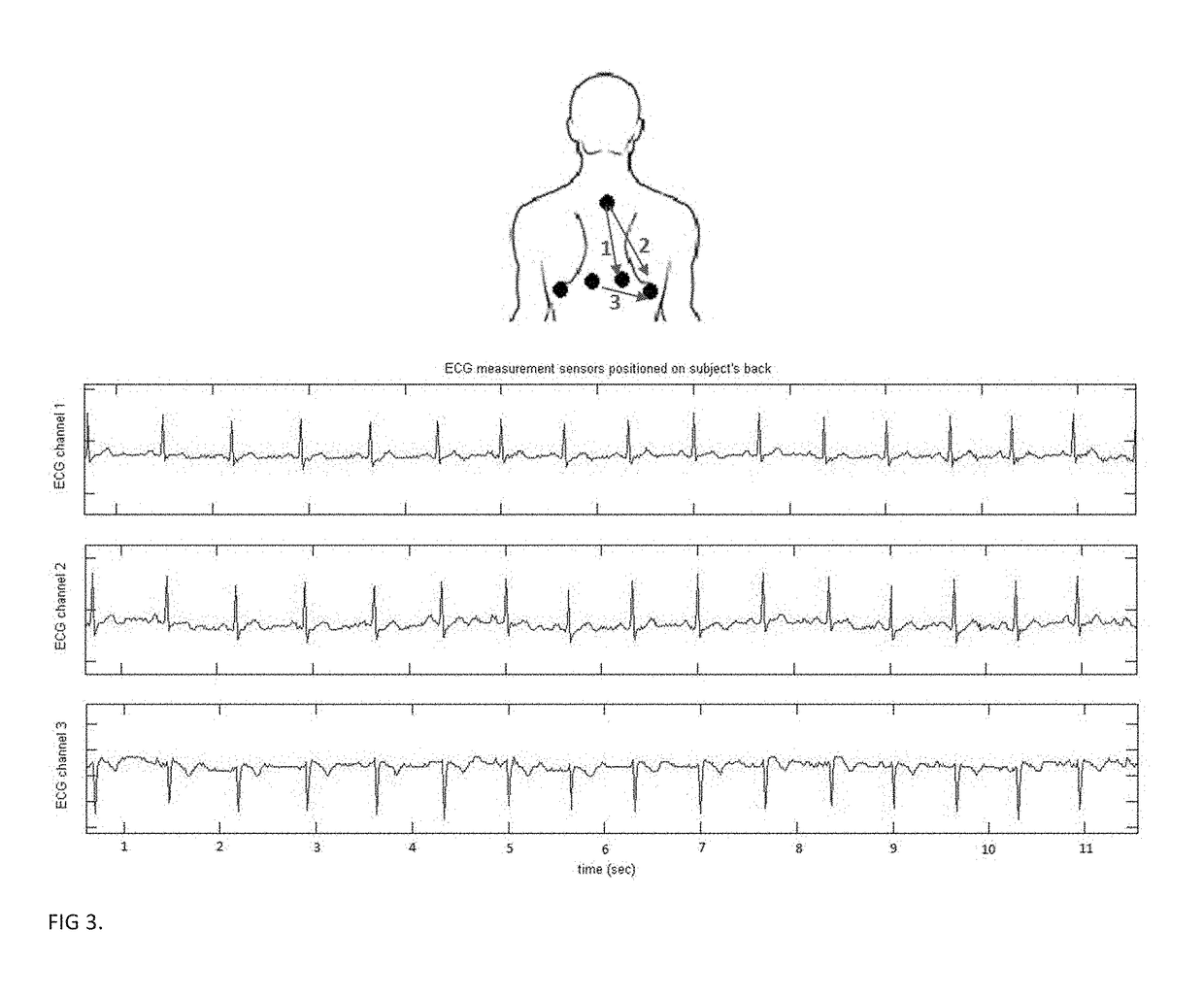

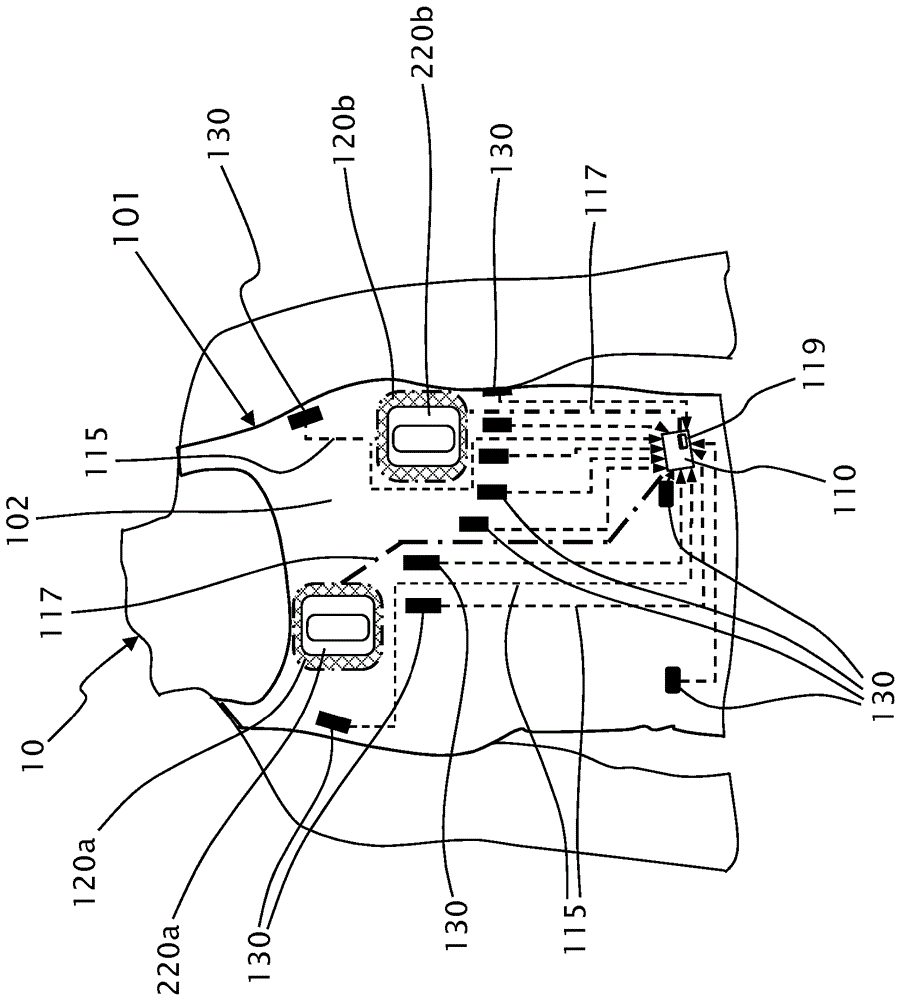

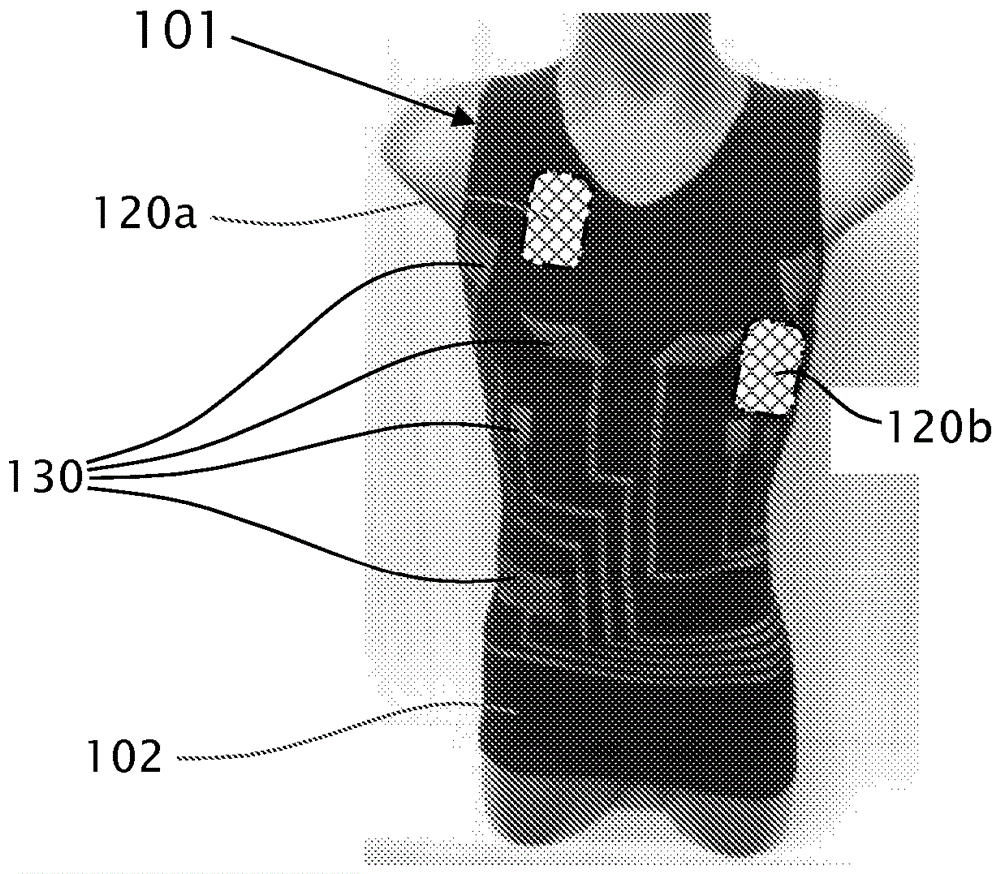

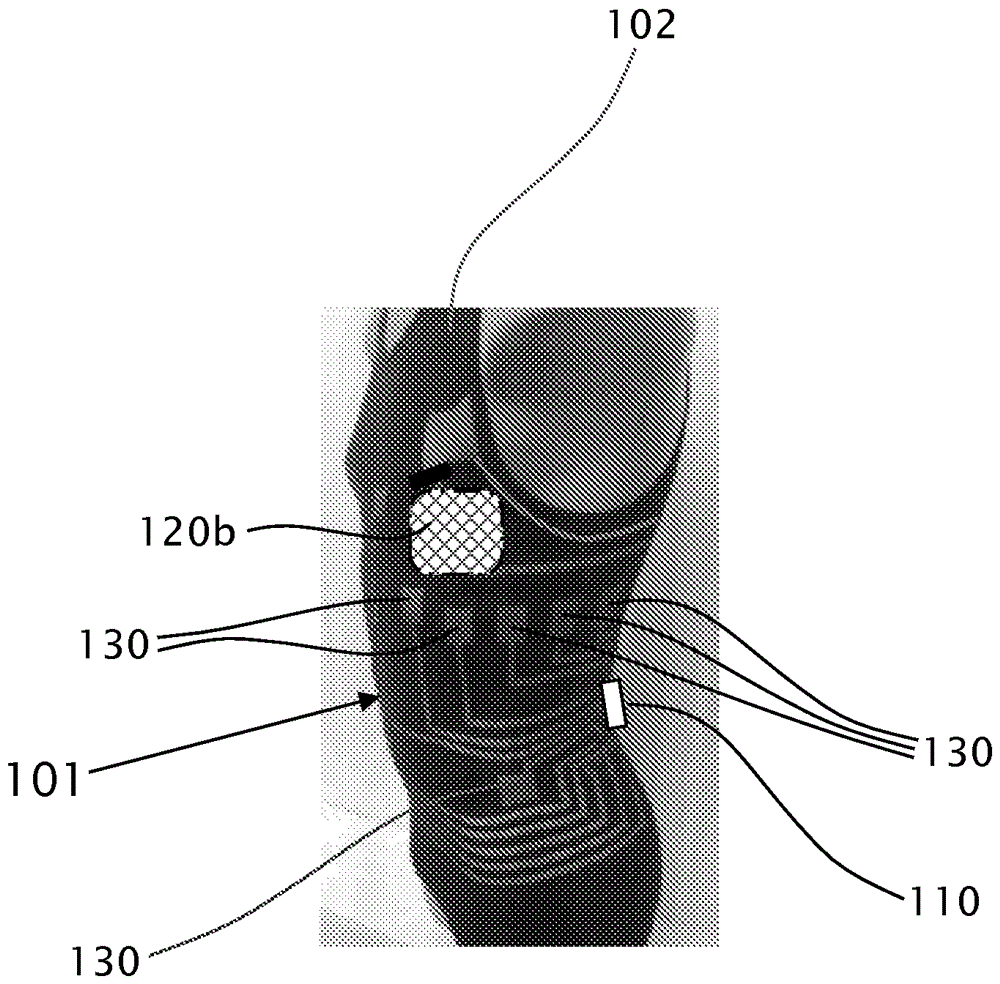

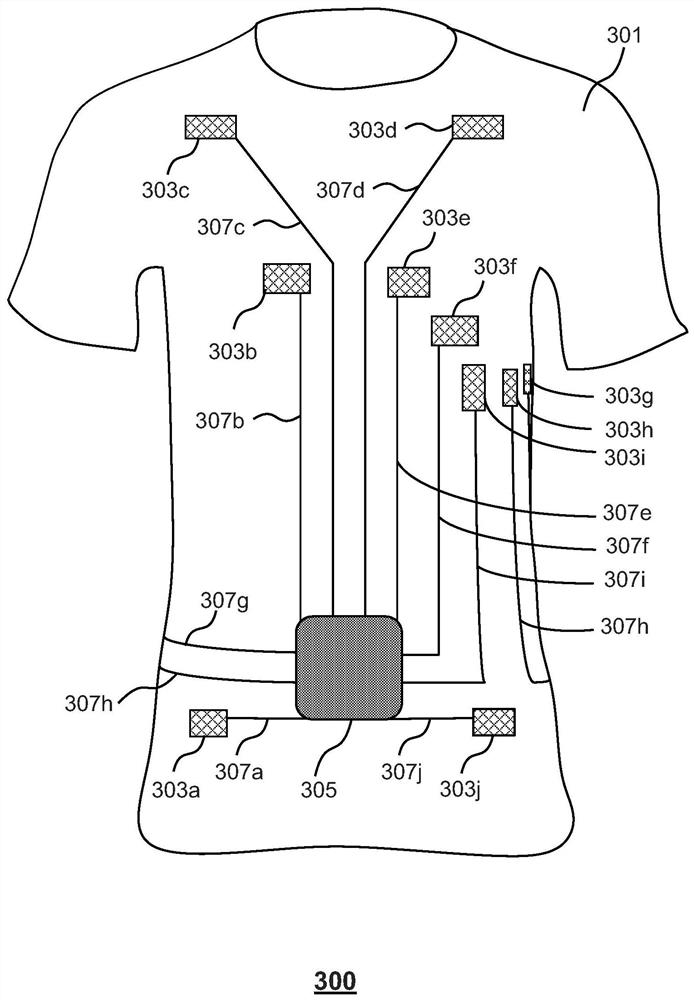

Independent wearable health monitoring system, adapted to interface with a treatment device

InactiveUS20160256104A1ElectrocardiographyEvaluation of blood vesselsTextile sensorsTherapeutic Devices

An independent wearable health monitoring system, configured for use by a living being on a daily basis. The system includes a knitted garment worn by the living being adjacently to preconfigured body locations, a garment-processing device having processor, and a multiplicity of sensors adapted to measure health parameters, wherein at least some sensors are integrally knitted with the knitted garment, and wherein the knitted textile sensors include electrodes adapted to provide ECG data. The system further includes an interface adapted to operatively connect at least one external medical device to the garment-processing device. Preferably, the health monitoring system further includes two conductive, integrally knitted pads operatively disposed tightly adjacently to the skin of the monitored living being, adapted to facilitate placing of a respective defibrillator paddles thereon and applying defibrillator shocks. Preferably, the garment-processing device controls the activation and deactivation of the defibrillator shocks.

Owner:AUTONETWORKS TECH LTD

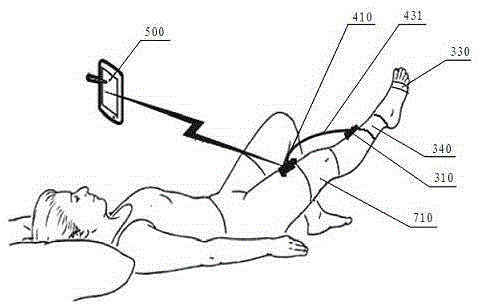

Wearable human achilles tendon information collection and monitoring system

ActiveCN105380602AEasy to collectThe results of the analysis are comprehensiveDiagnostic recording/measuringSensorsAchilles tendonTextile sensors

The invention relates to a wearable human achilles tendon information collection and monitoring system. The wearable human achilles tendon information collection and monitoring system comprises a foot cover, a human achilles tendon information collector, a human physiological parameter collector, a micro vibrator, a data collection and control device, a user manual device, a mobile terminal and an open type cloud processing platform, all the collectors are arranged on the foot cover and each preferably adopts a corresponding soft textile sensor, relative achilles tendon signals and / or physiological parameters obtained through the collectors are subjected to primary process through the mobile terminal and sent to the cloud processing platform, analysis and process are conducted through a data analysis and feature extraction algorithm, a final report containing an analysis result is automatically generated, when a person has discomfort symptoms, the user can manually record the discomfort degree through the user manual device, changes of all indexes at this moment are compared through a timer axis, and a damage alarming waveform graph is set. According to the wearable human achilles tendon information collection and monitoring system, the analysis result is more comprehensive, detailed and accurate, and the wearable human achilles tendon information collection and monitoring system can be used by subjects extremely conveniently.

Owner:汪毅 +3

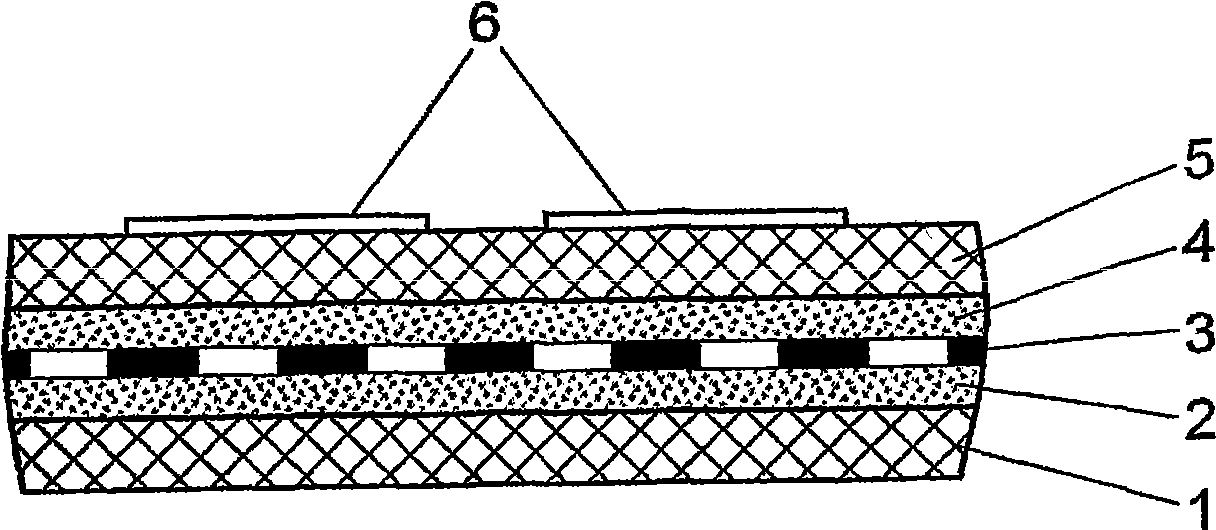

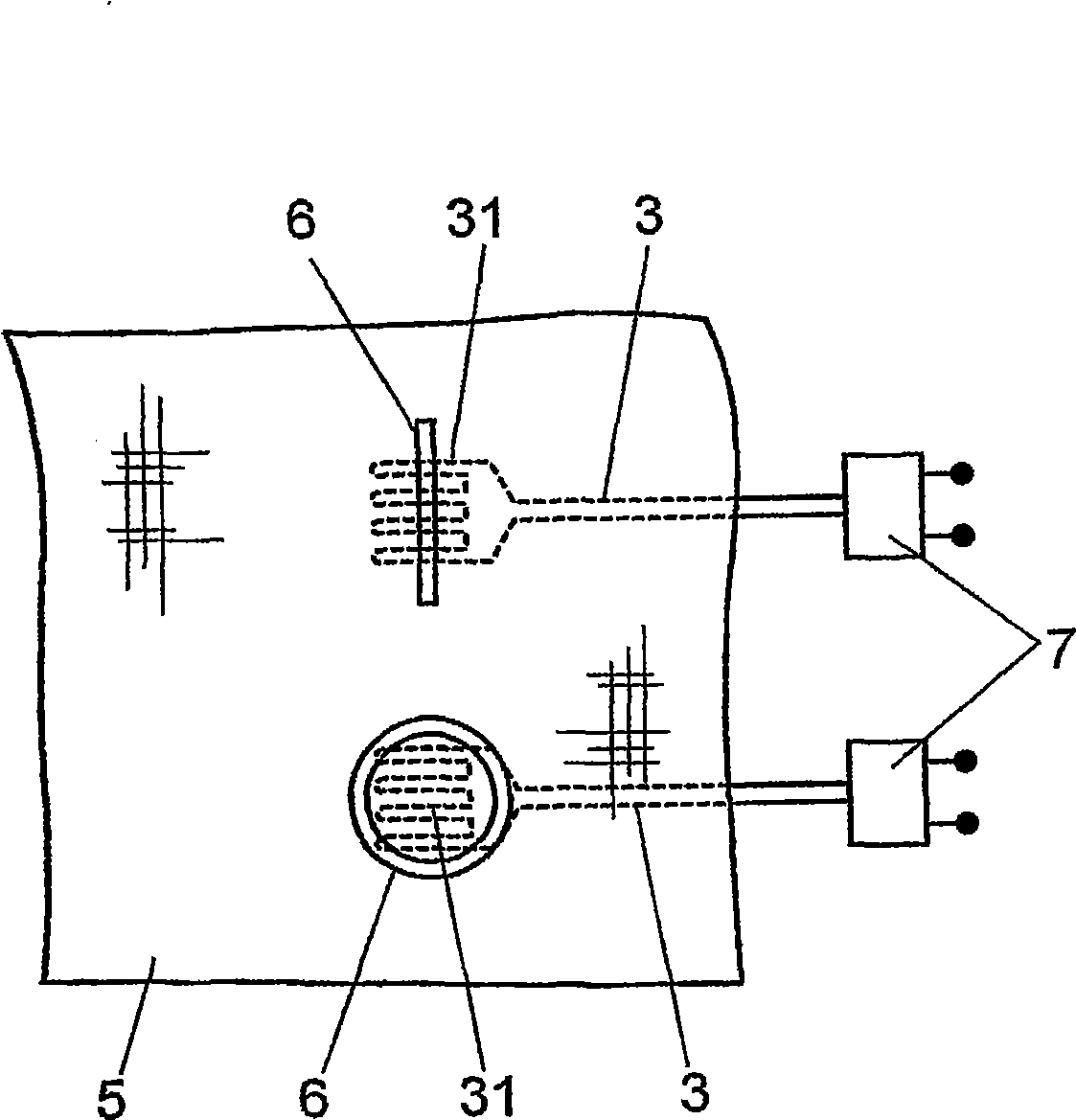

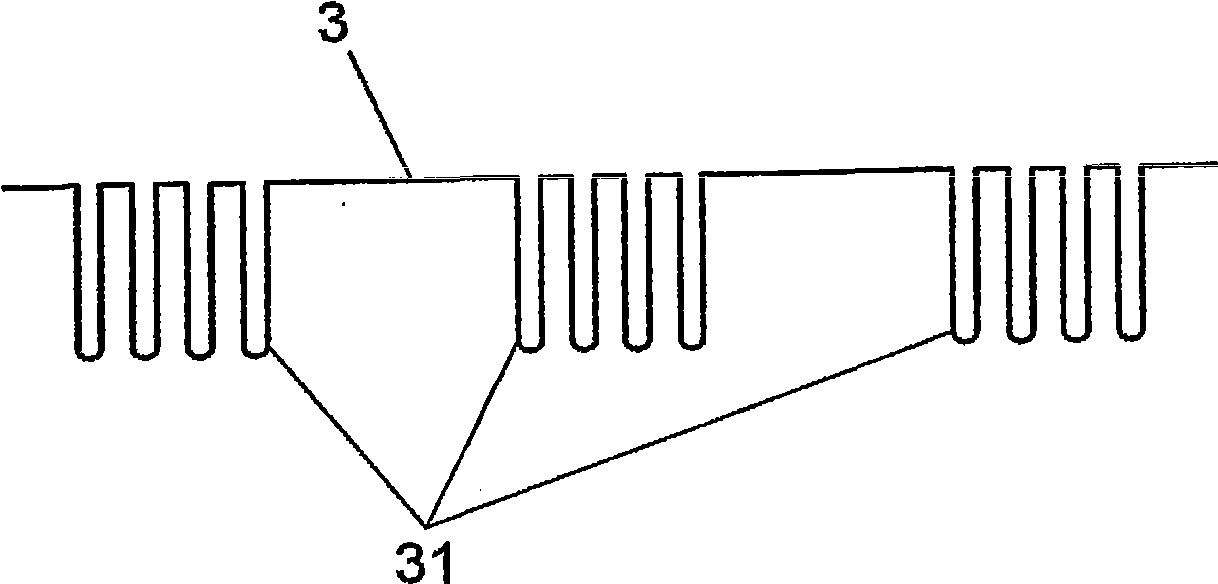

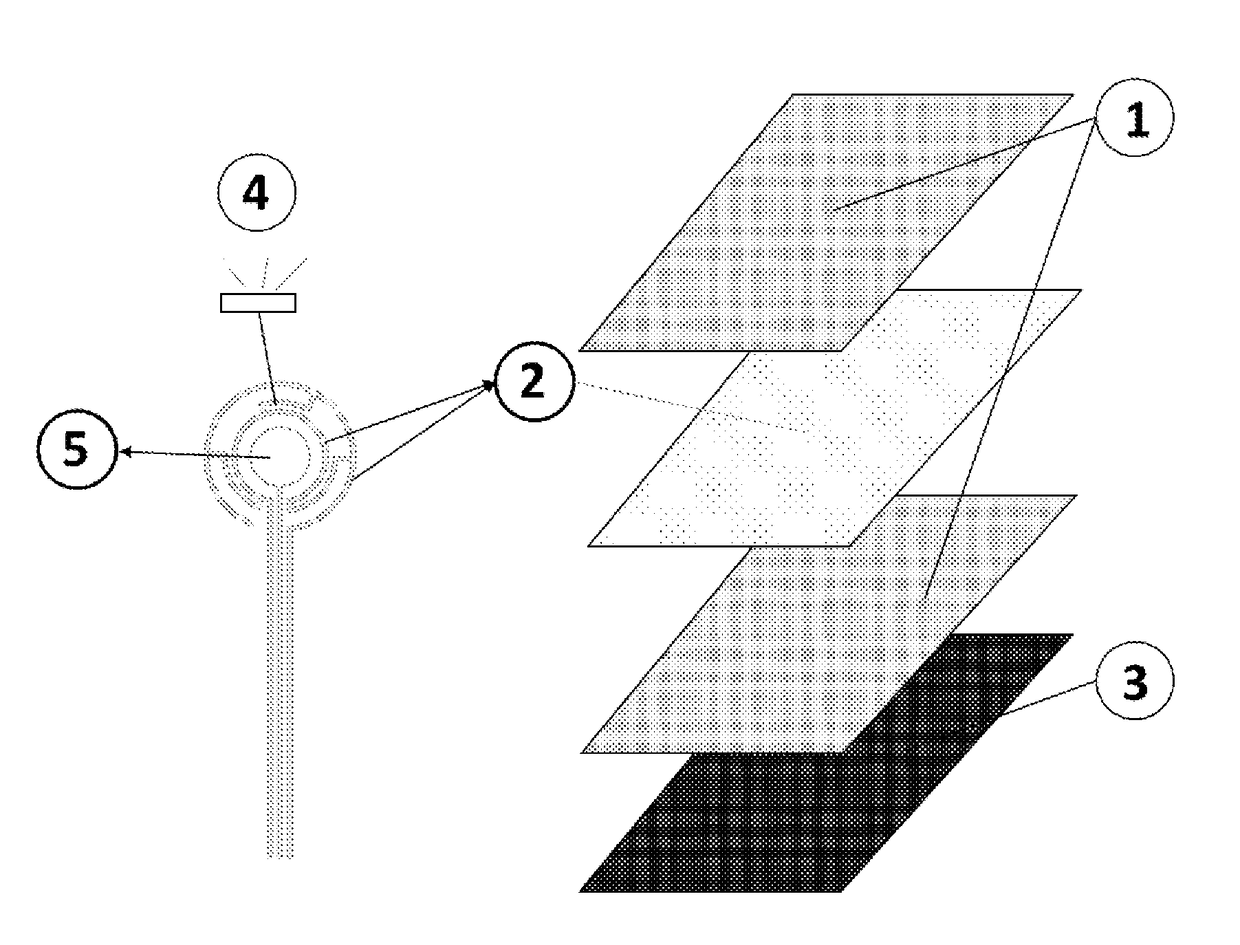

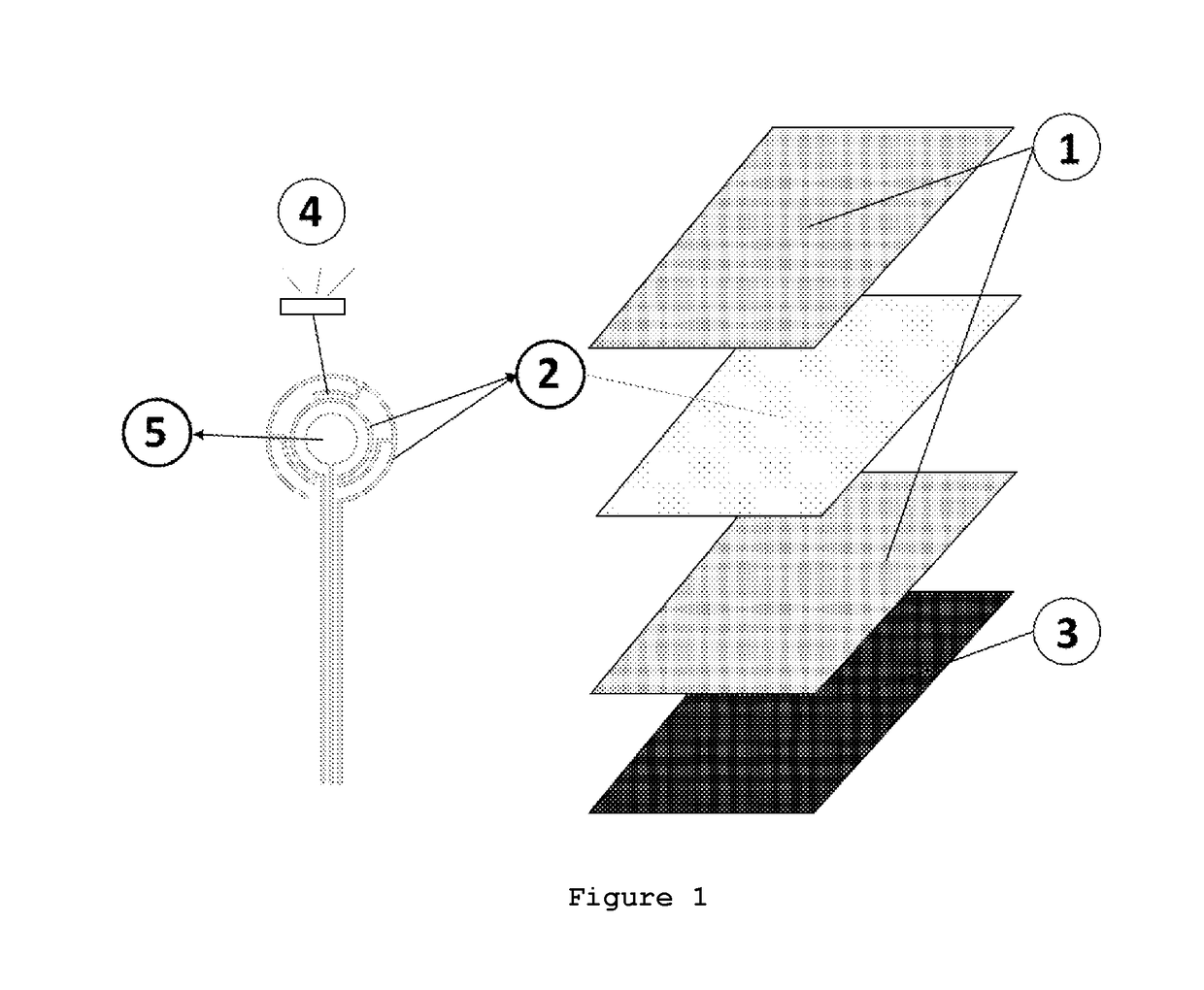

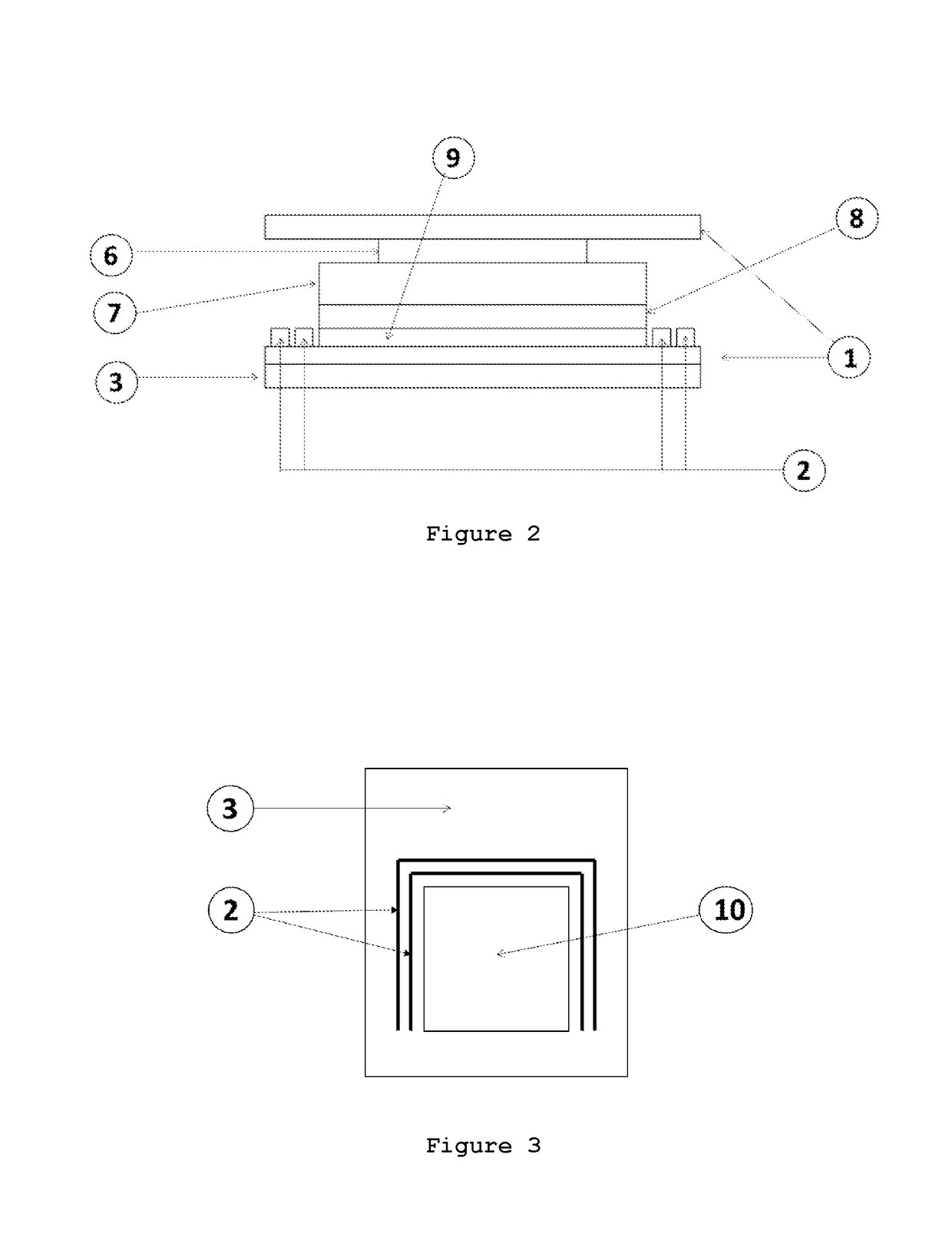

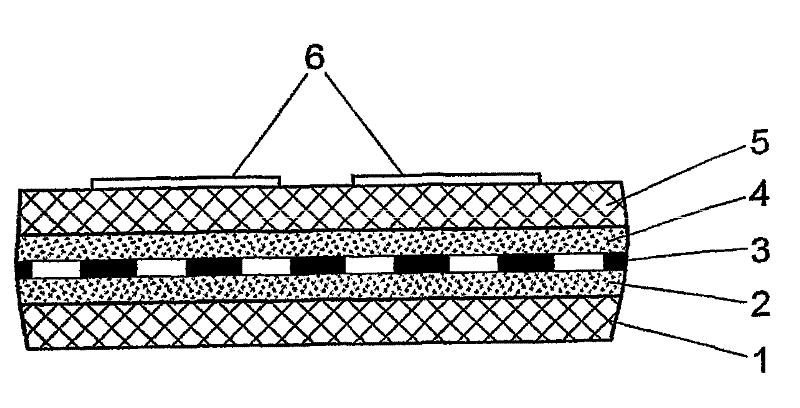

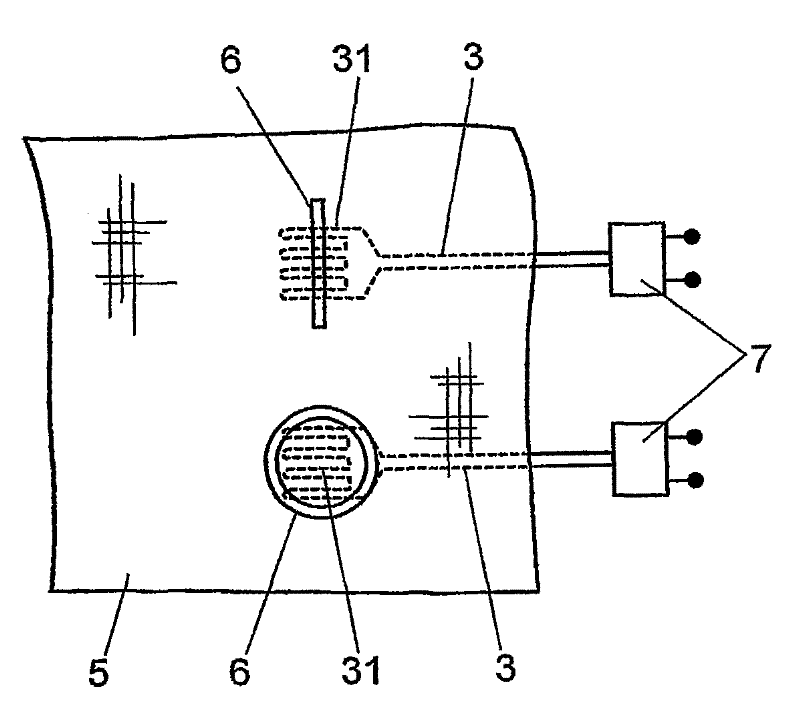

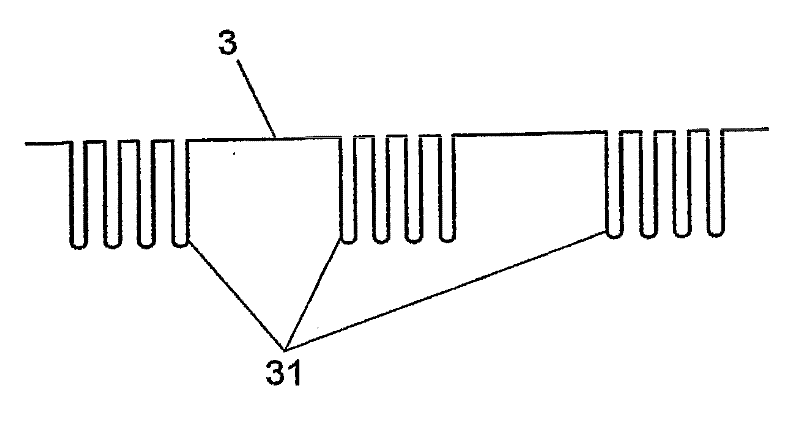

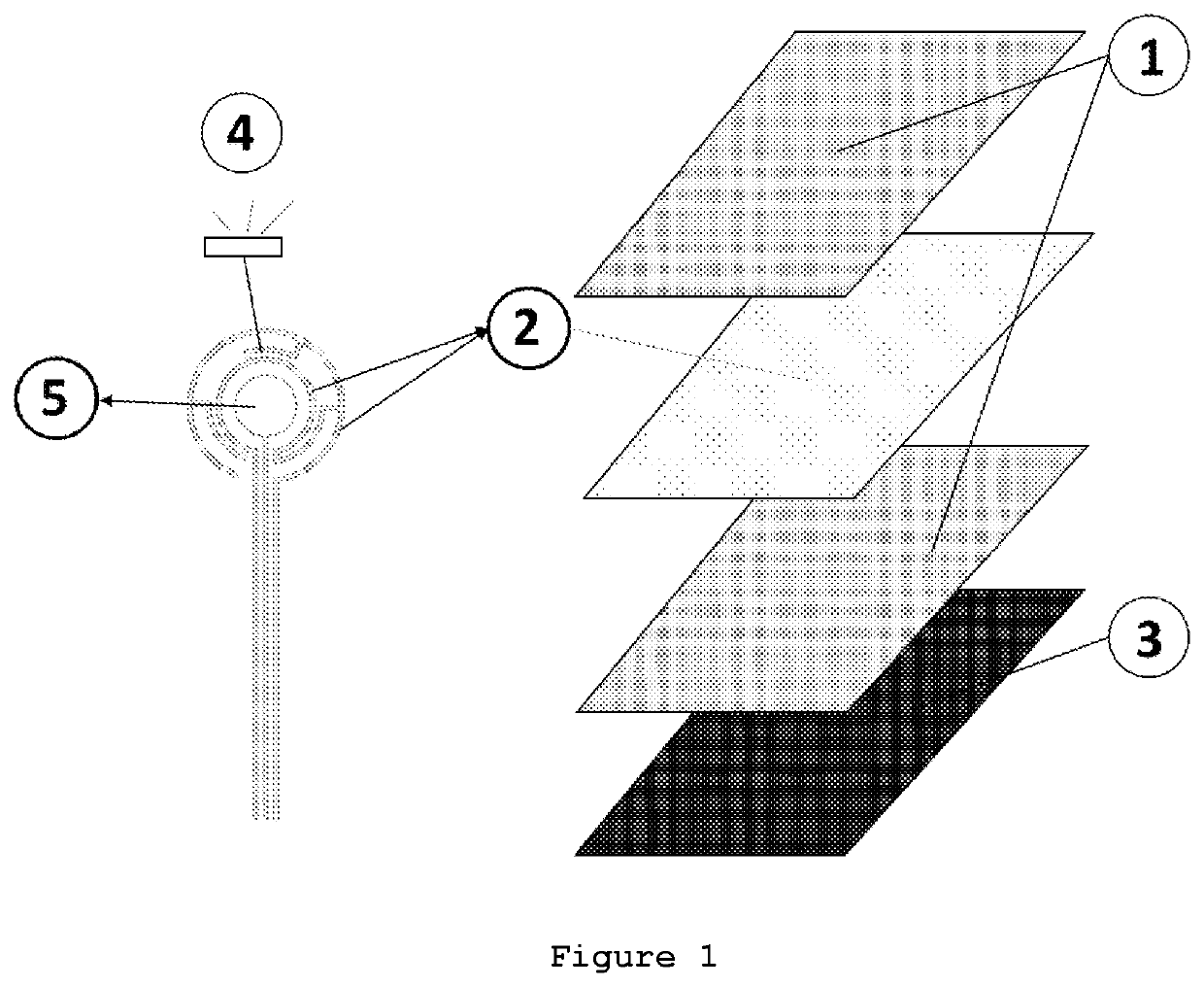

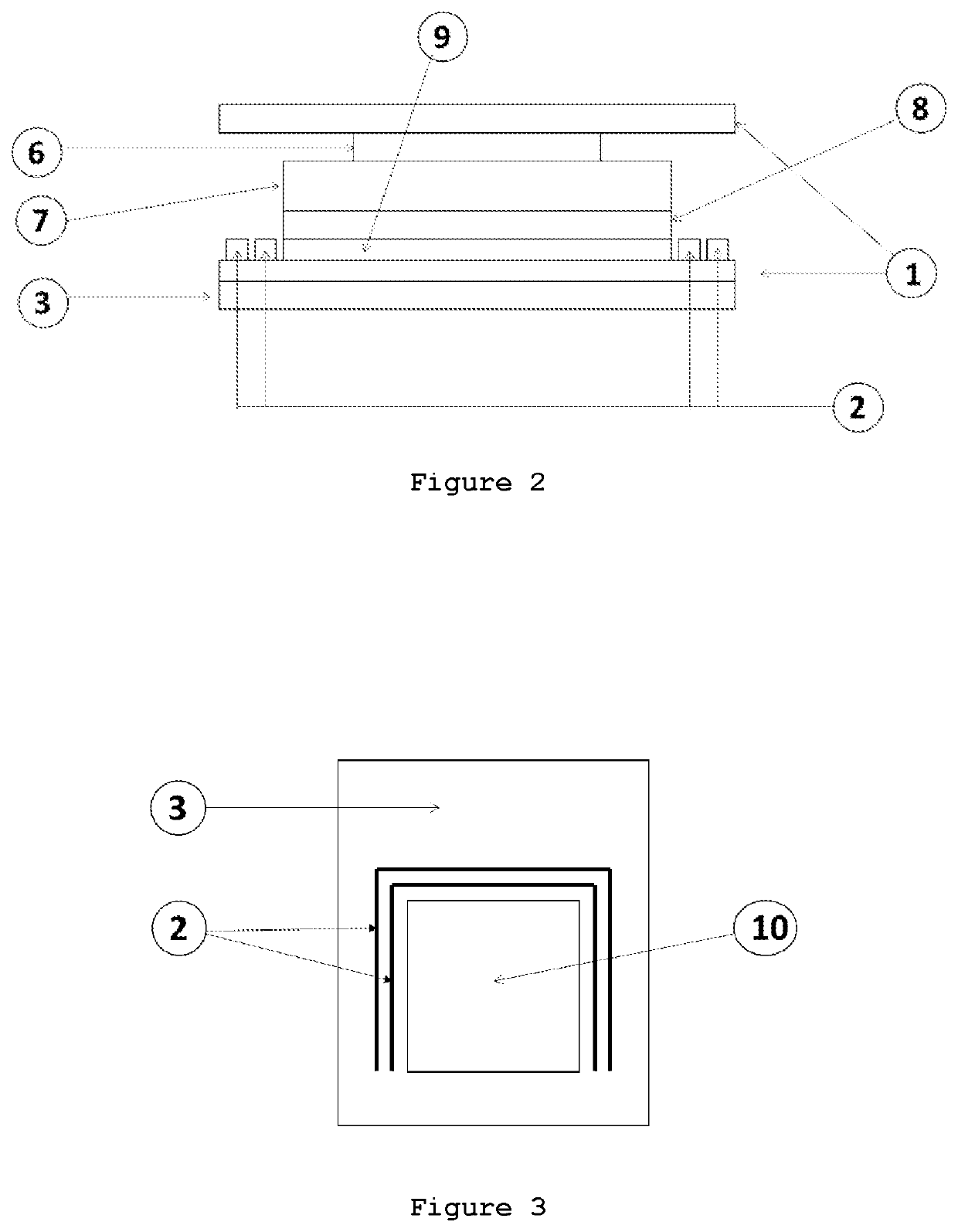

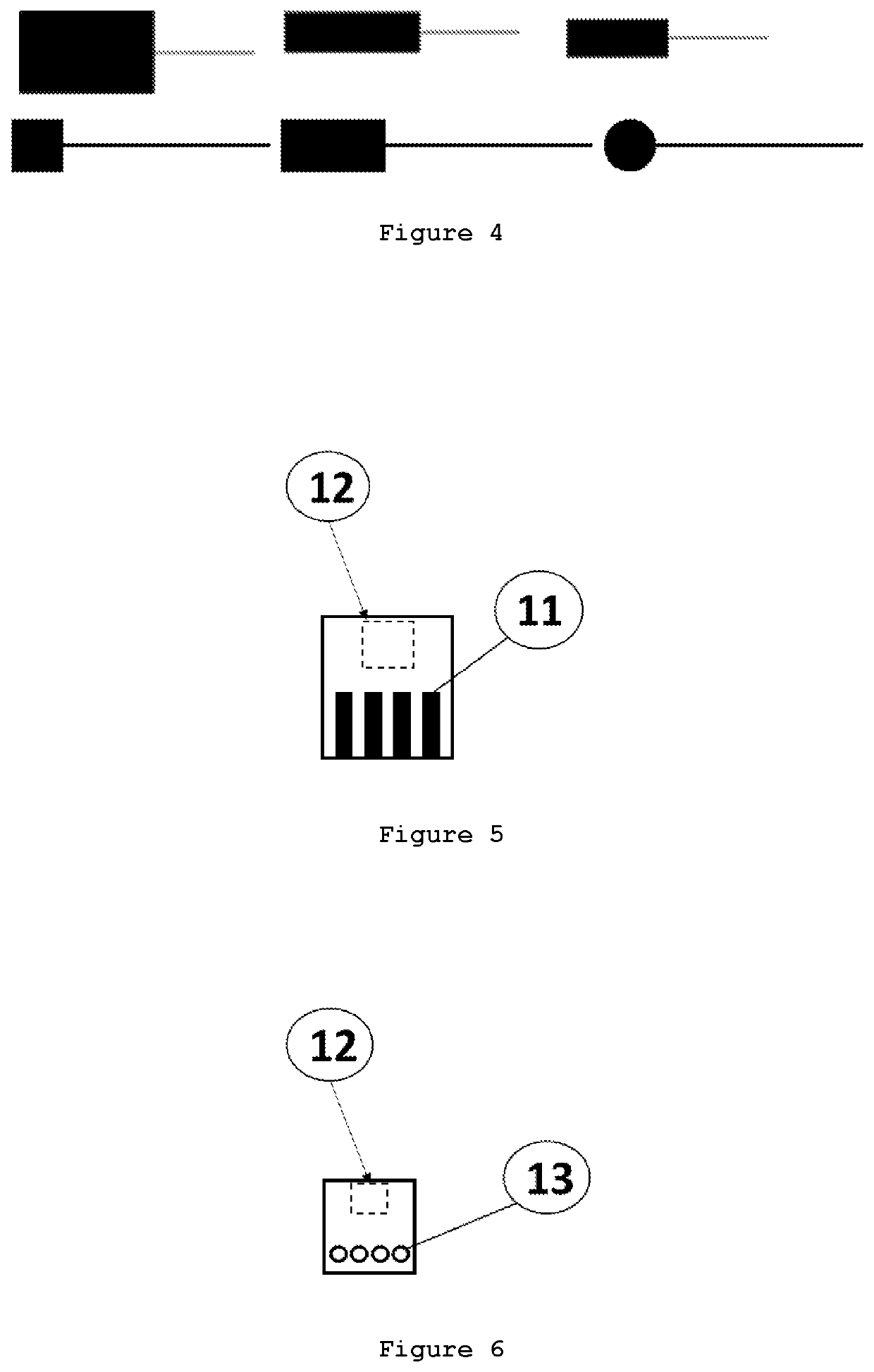

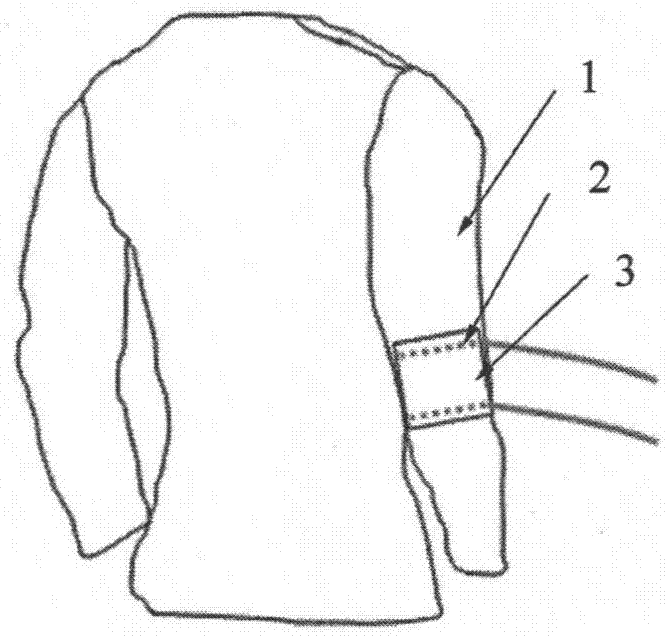

Torsion and/or tension and/or pressure textile sensor

InactiveCN101479582AProcessing speedForce measurementOhmic-resistance heatingTextile sensorsEngineering

The invention relates to a torsion and / or tension and / or pressure textile sensor. The textile sensor is a resistive-type sensor consisting of: at least one base layer of fabric (1) comprising any composition and / or mixture and produced using any technique; optionally a surface treatment (2) in order to render the surface of the fabric (1) more uniform; a single conductive layer (3) having tracks distributed geometrically such as to define areas (31) sensitive to stresses from conductive fluids and an encapsulation and protection layer (4) on the conductive layer (3); optionally an upper fabric layer (5); and a least one signal converter (7) which is connected to the tracks, such that when one of the above-mentioned areas (31) is subjected to pressure, tension or torsion a large variation in the resistance of said track is produced, which can be detected by the converter (7). The sensor optionally includes an imprint (6) defining the aforementioned areas (31) on the outer face of either of the fabric layers (1,5).

Owner:FUNDACIO PRIVADA PER A LA INNOVACIO TEXTIL DIGUALADA

Method for the production of conductive flexible textile arrays

ActiveUS7531203B2Stable levelHigh sensitivityMolten spray coatingRadiation applicationsCapacitanceTextile sensors

A method for the production of a conductive flexible textile array. The method includes the application of an oxidizing agent to selected areas of the textile; coating the textile with pyrrole by vapor deposition to form a conductive coated textile having a polypyrrole network; stabilizing the conductive coated textile; and forming the conductive flexible textile arrays as a sensor. With this method of production, the degree of polymerization of the conjugated polymer, the morphology and the rate of the capacitance delay is carefully controlled. As such, stable flexible textile sensors are produced with various levels of sensitivities and conductivities which are particularly useful for designed applications.

Owner:THE HONG KONG POLYTECHNIC UNIV

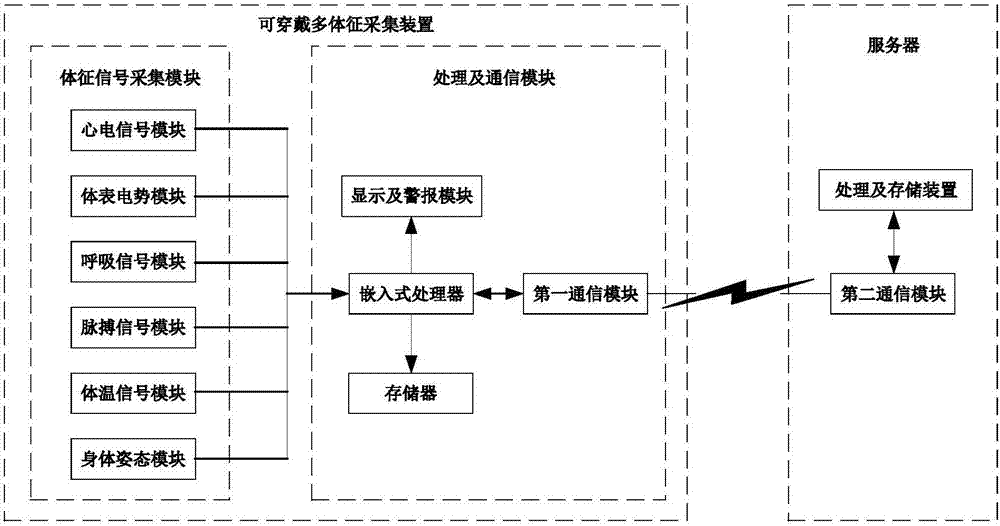

Wearable vital sign monitoring device and mental status monitoring method

ActiveCN107080527AReal-timeRealize early warningDiagnostic signal processingSensorsMental stateTextile sensors

The invention provides a wearable vital sign monitoring device and a mental status monitoring method. The wearable vital sign monitoring device comprises two parts, namely a wearable multi-sign acquiring device and a server, wherein the wearable multi-sign acquiring device consists of a vital sign acquiring module and a processing and communicating module; acquisition of different physiological signals is realized by the vital sign acquiring module; the physiological signals are processed and integrated by an embedded lower-power-consumption processor, then are transmitted to a server side by the communicating module in a wireless mode and are stored and processed in the server; the mental status monitoring method provides a method for evaluating a mental status on the basis of sign signal data. According to the wearable vital sign monitoring device and the mental status monitoring method provided by the invention, by combining with a flexible processing technique and using a textile electrode, leads and various textile sensors embedded into clothes, lightness and comfortableness of the device are ensured while multiple physiological parameters are acquired; further analysis, exploitation and utilization of the acquired sign parameters are realized, and real-time judgment and early warning of a body and the mental status are realized.

Owner:SOUTHEAST UNIV

Textile conveyor

InactiveCN105540203APrevent fallingPrevent deviationConveyorsControl devices for conveyorsTextile sensorsEngineering

The invention primarily discloses a textile conveyor. According to the technical scheme, the textile conveyor comprises a rack, a driver, a roller bracket and a conveyor belt, wherein supporting bases are arranged on the left side and right side of the rack; a portal frame is arranged on the supporting bases; sensor plates are arranged on the left side and right side of the conveyor belt; each sensor plate is internally provided with a first controller; each sensor plate is provided with a regulating mechanism; each regulating mechanism comprises a regulating rod and an air cylinder; each first controller is electrically connected with the corresponding air cylinder; each sensor plate is further provided with a textile sensor; each textile sensor comprises an infrared emitter, an infrared receiver and a counter; a mobile device is arranged on the top of the portal frame and provided with a drier. The textile conveyor is simple in structure, reasonable in design and capable of preventing textiles from deflecting, measuring the quantity of the conveyed textiles and drying the textiles.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

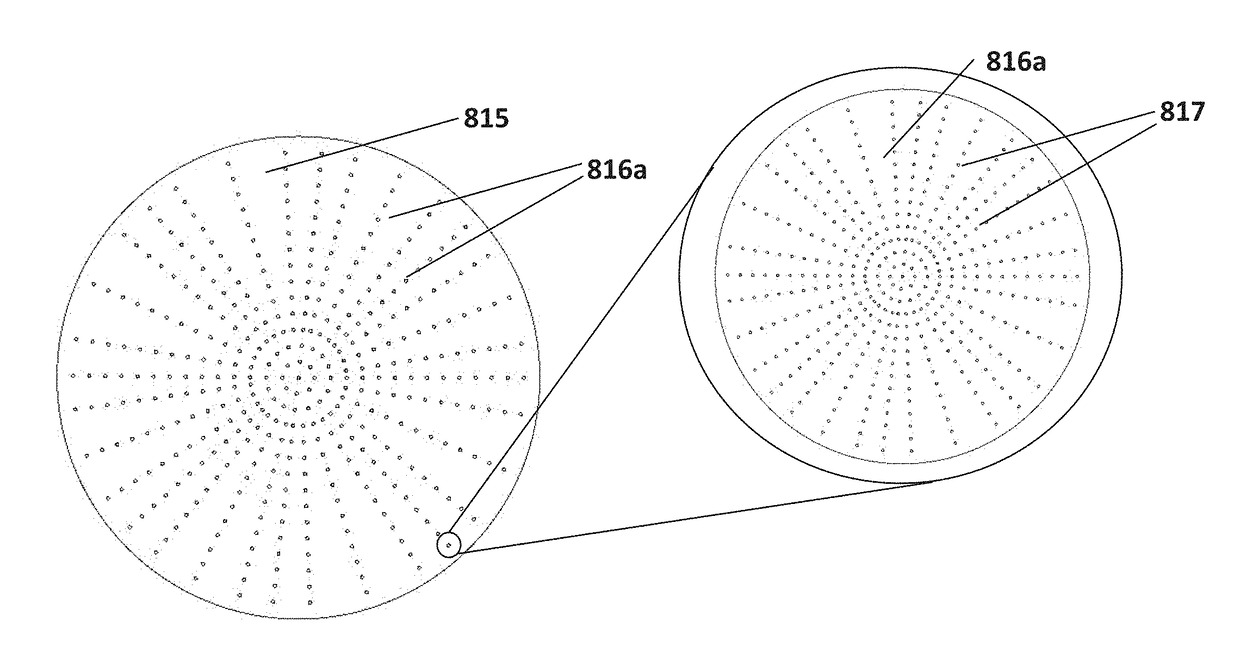

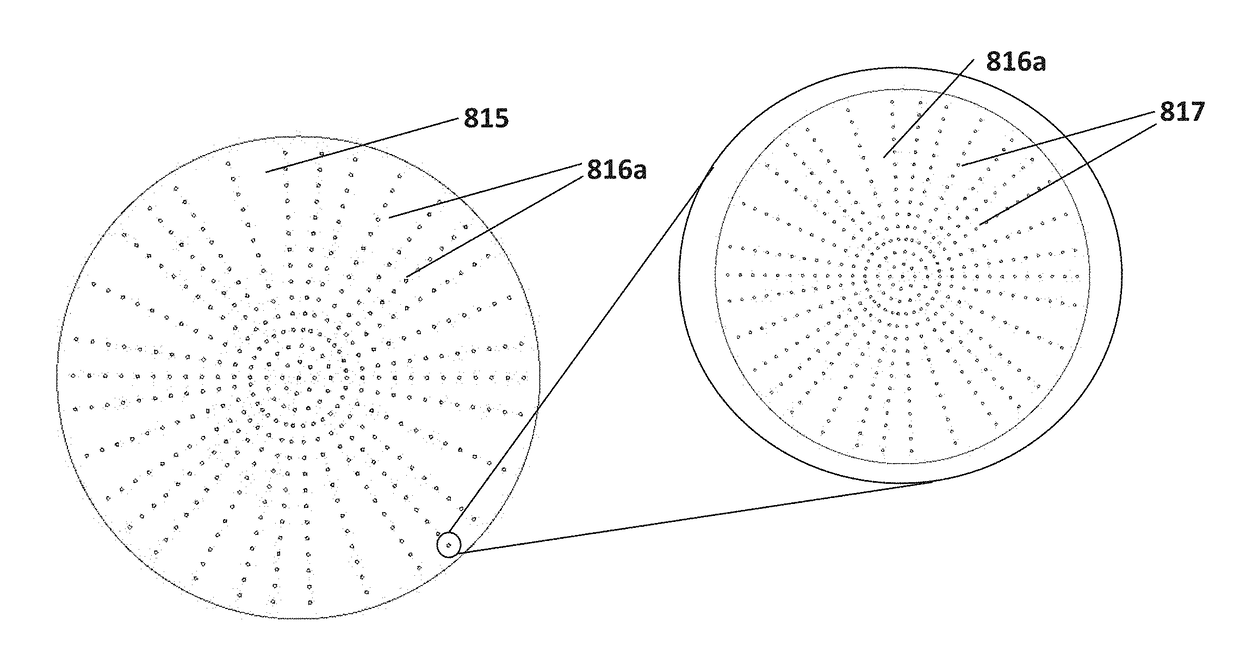

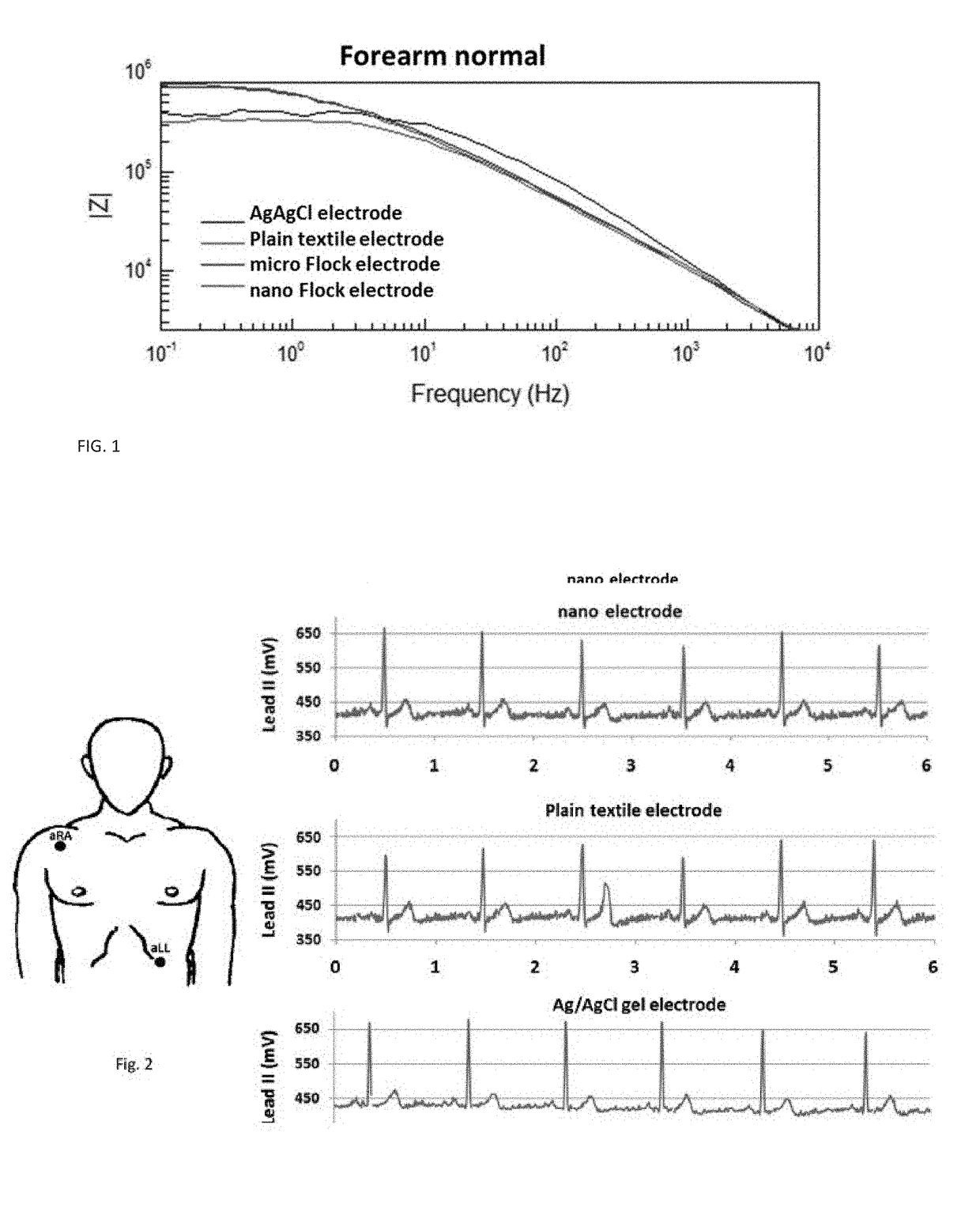

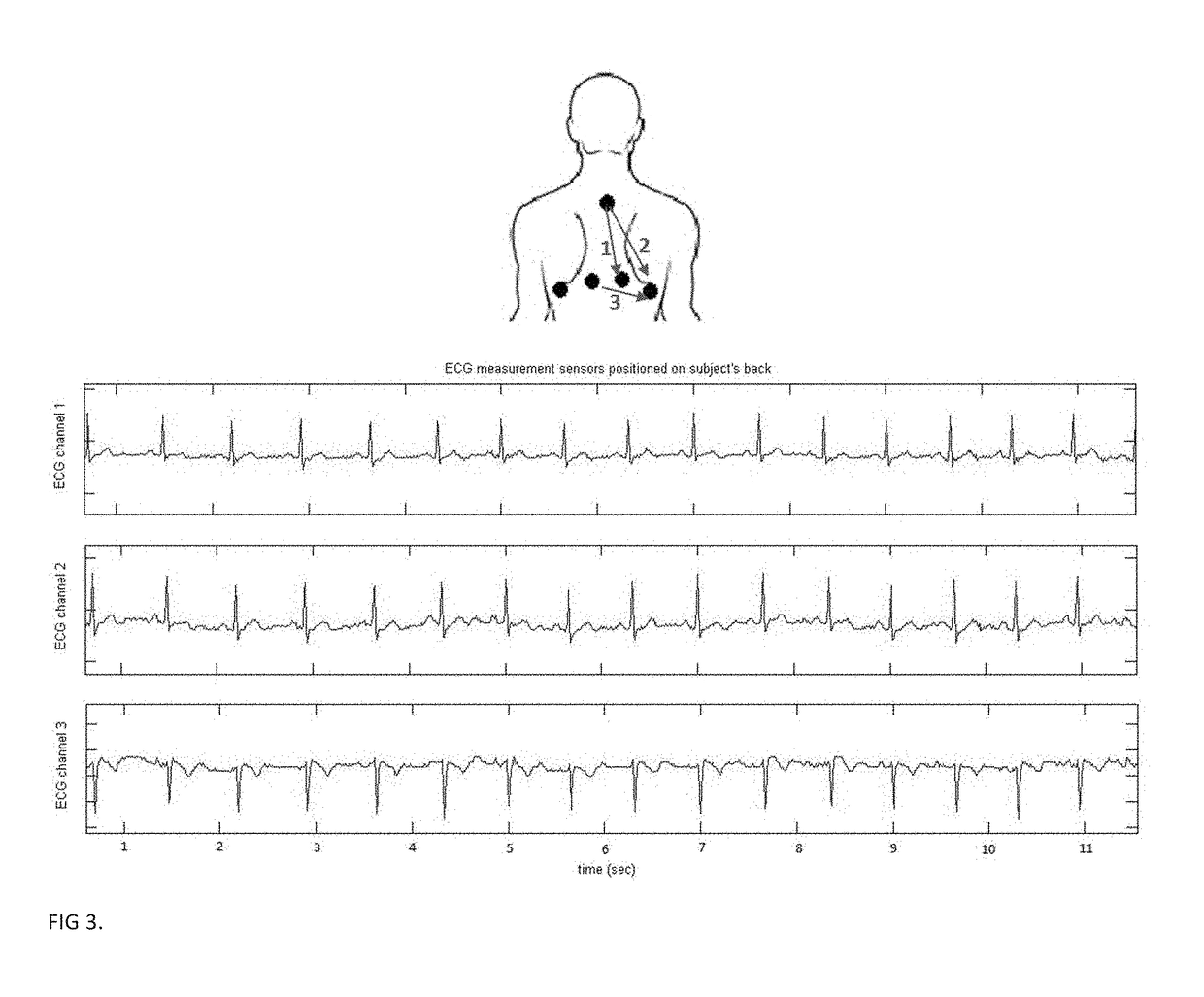

Large scale manufacturing of hybrid nanostructured textile sensors

ActiveUS20170226643A1Material nanotechnologyLiquid surface applicatorsMicro structureTextile sensors

A process for the large-scale manufacturing vertically standing hybrid nanometer scale structures of different geometries including fractal architecture of nanostructure within a nano / micro structures made of flexible materials, on a flexible substrate including textiles is disclosed. The structures increase the surface area of the substrate. The structures maybe coated with materials that are sensitive to various physical parameters or chemicals such as but not limited to humidity, pressure, atmospheric pressure, and electromagnetic signals originating from biological or non-biological sources, volatile gases and pH. The increased surface area achieved through the disclosed process is intended to improve the sensitivity of the sensors formed by coating of the structure and substrate with a material which can be used to sense physical parameters and chemicals as listed previously. An embodiment with the structures on a textile substrate coated with a conductive, malleable and bio-compatible sensing material for use as a biopotential measurement electrode is provided.

Owner:NANOWEAR

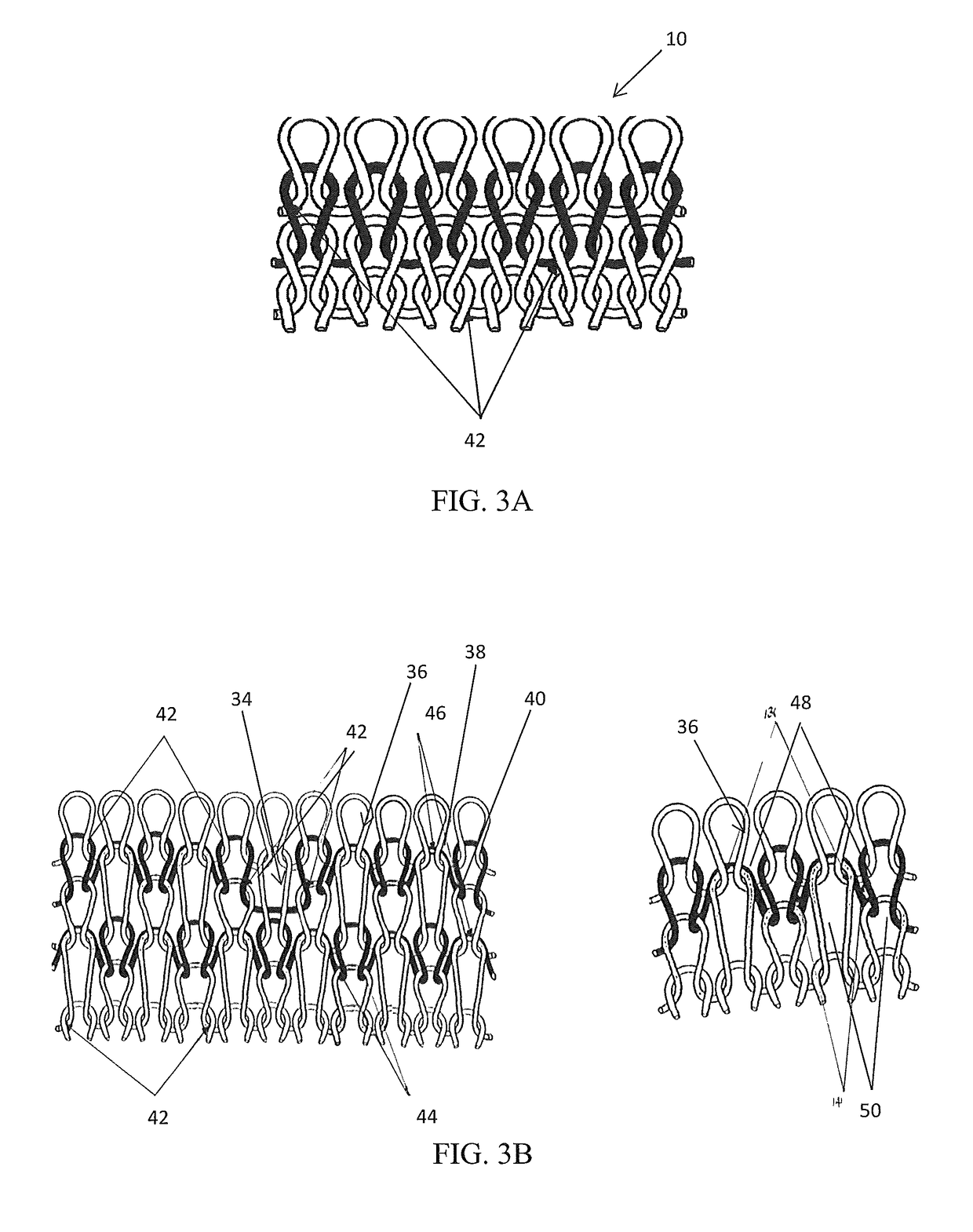

Method for making electrically conductive textiles and textile sensor

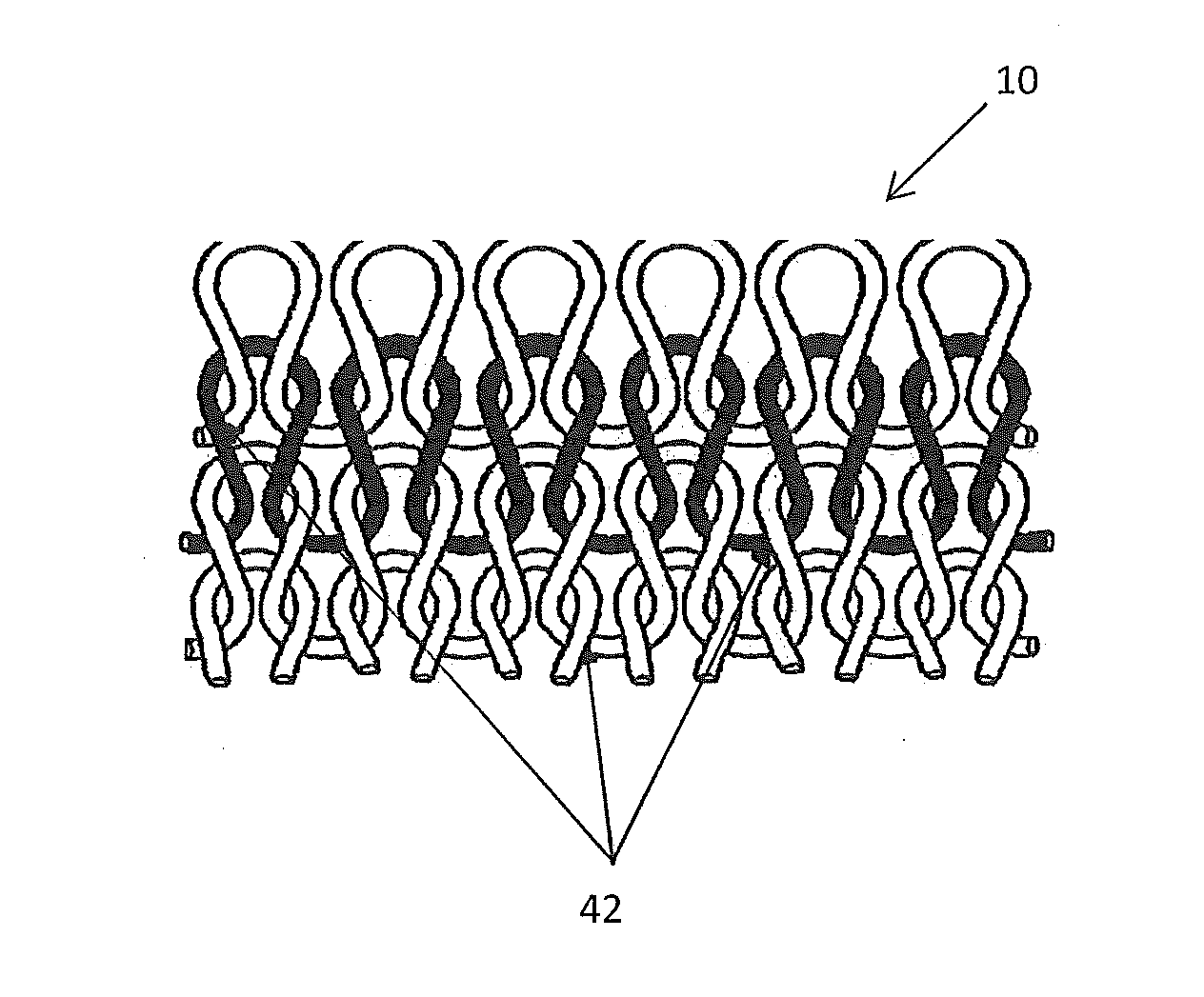

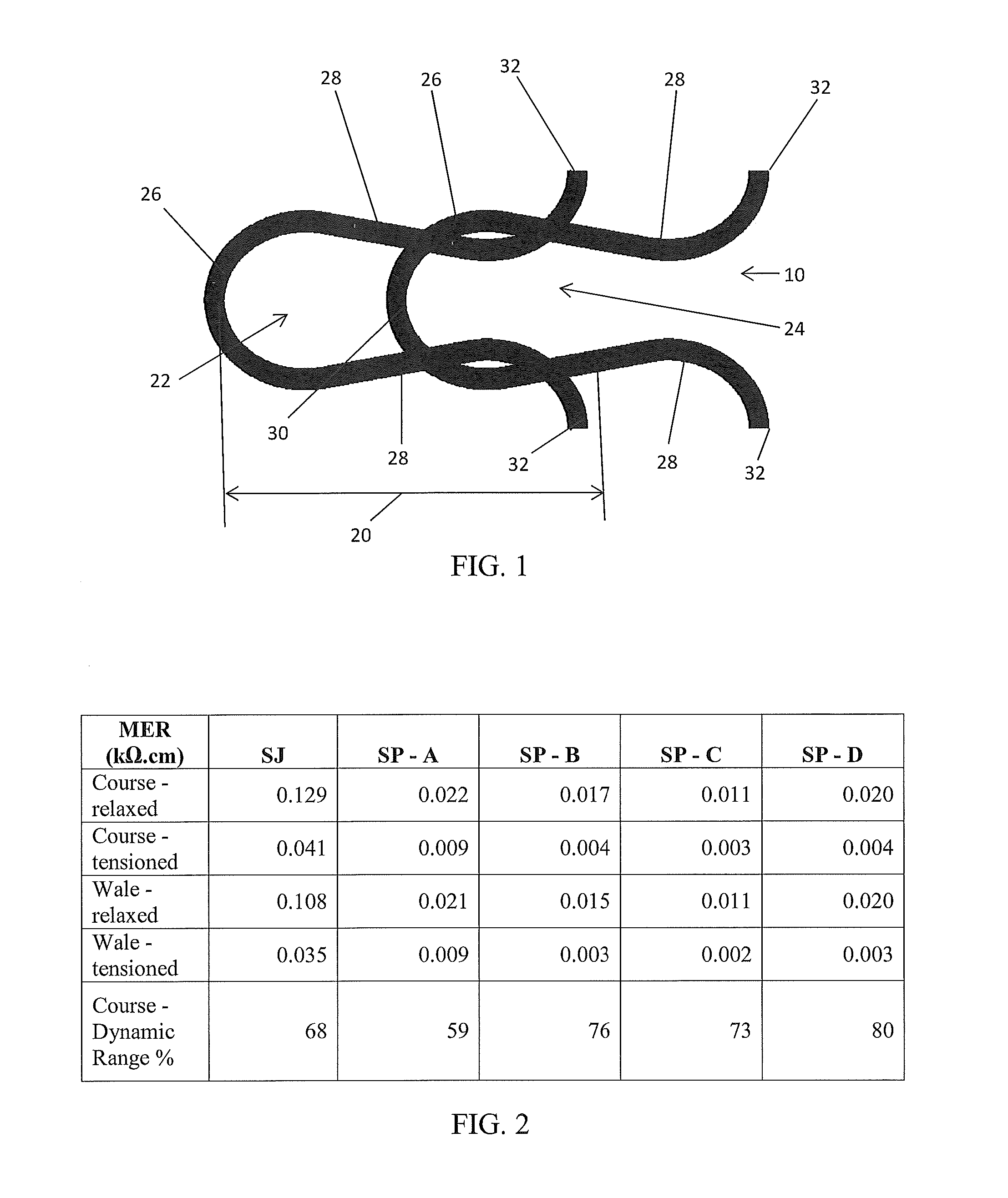

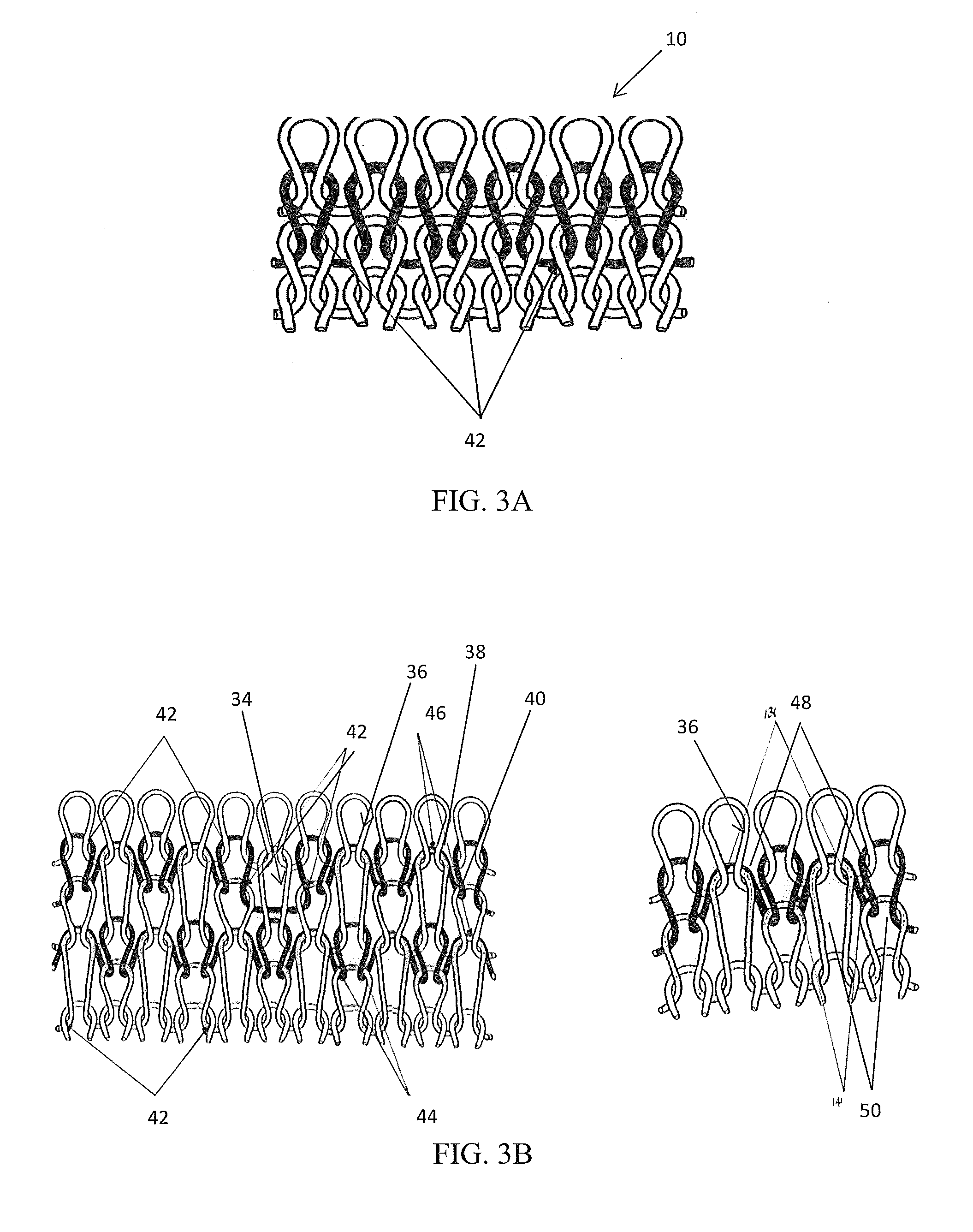

ActiveUS10119208B2Increase contact resistanceReduce sensitivityWeft knittingOrnamental textile articlesYarnElectrical resistance and conductance

A method for making a textile sensor and a textile sensor can include selecting a combination of variables from the group consisting of yarn variables, stitch variables, and textile variables; and knitting an electrically conductive yarn in the textile sensor in accordance with the selected combination of variables, wherein the combination of variables is selected so as to provide a controlled amount of contact resistance in the textile sensor. The method and textile can further include a capacitive textile-sensor having at least two integrally knit capacitor plate elements and having a configuration adapted for a sensing activity. Resistance in the textile sensor can automatically calibrate to a stable baseline level after the textile sensor is applied to a body.

Owner:FOOTFALLS & HEARTBEATS (UK) LTD

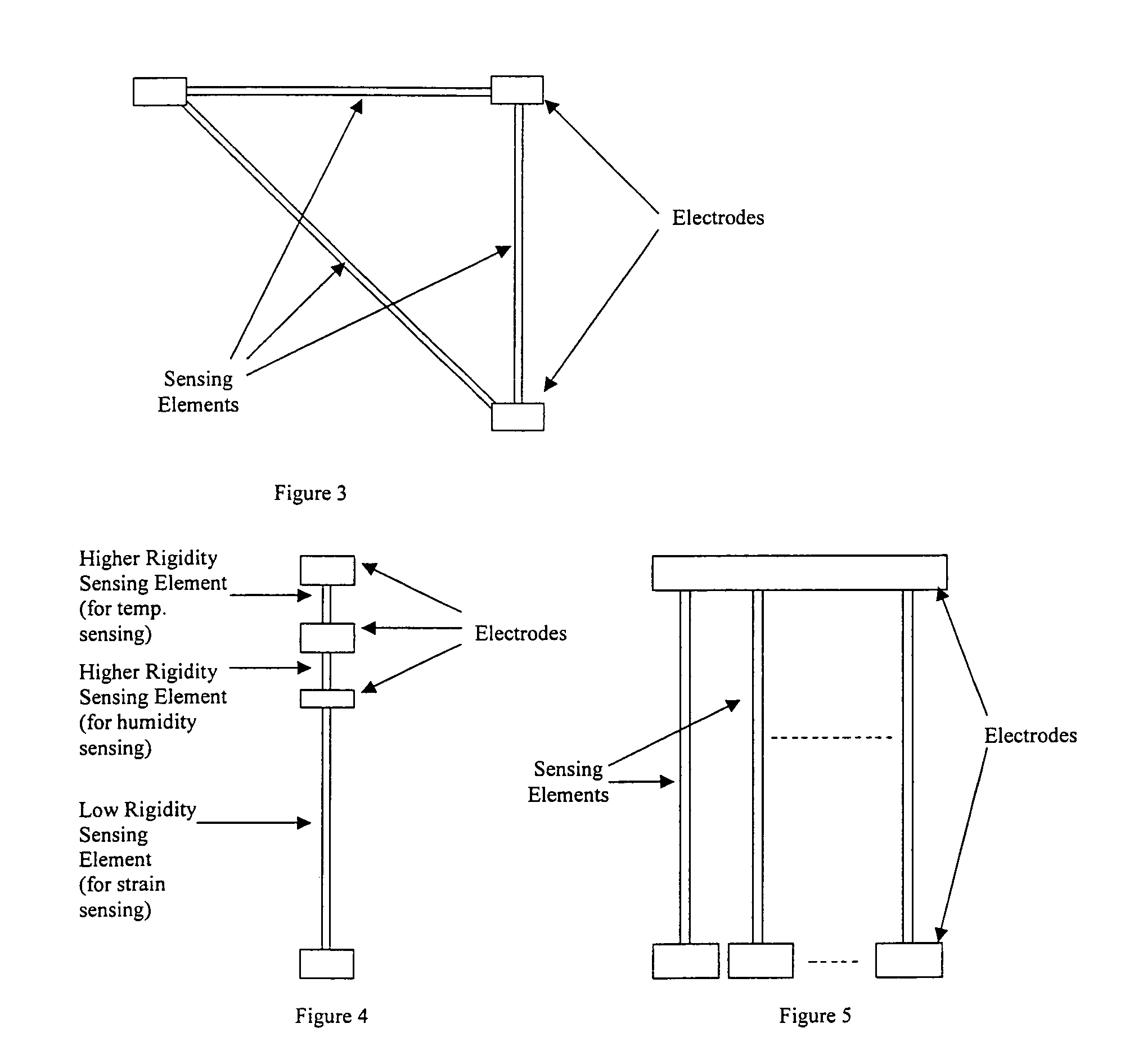

Multifunctional textile sensor

ActiveUS20180302983A1Small sizeAvoid the needPrinted circuit assemblingPrinted circuit aspectsElectricityTextile sensors

The present application describes the creation of a flexible textile structure with sensing and lighting capabilities without the loss of important features of a typical textile, for instance, comfort, seamless and mechanical flexibility. As sensing applications are described three different approaches that may or may not work together in the same system: a directly printed self-capacitive sensor, a knitted textile sensor and the integration of temperature / humidity bulk capacitive sensors directly on the textile. As lighting applications for decorative and signage purposes are used two different approaches that could work individually or together: an electroluminescent sensing device and the use of a hybrid sensor that includes the use of SMD LEDs and a printed self-capacitive sensor. The sensing and lighting applications previously described can be used, as an example, inside an automobile passenger compartment since they are easily integrated on seats with different geometries, armrests and central panels to substitute common mechanical buttons and sensing devices, and create a cleaner and seamless environment, following current tendencies in car interiors.

Owner:CONTINENTAL IND TEXTIL DO AVE SA

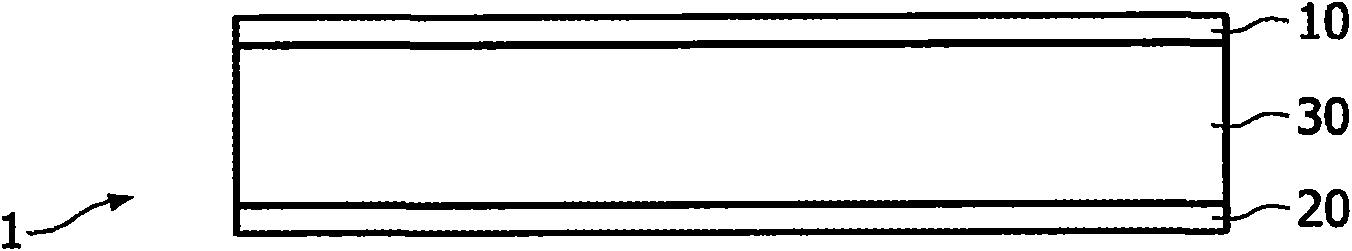

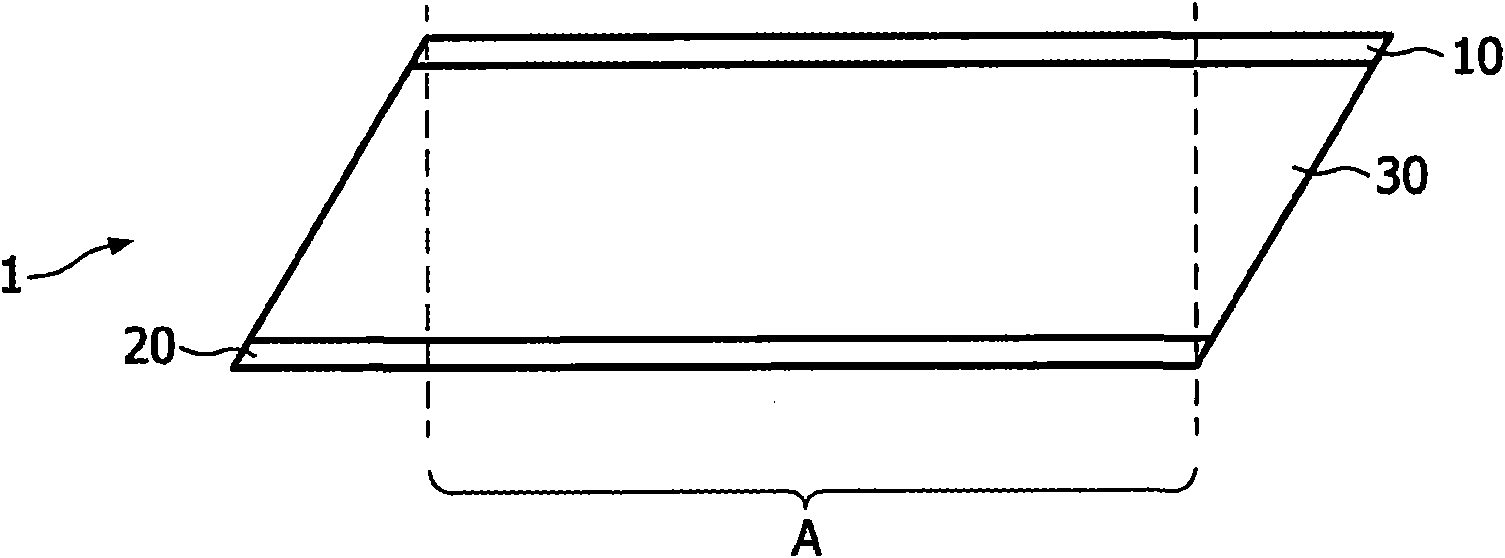

Torsion and/or tension and/or pressure textile sensor

InactiveCN101479582BProcessing speedForce measurementOhmic-resistance heatingTextile sensorsEngineering

The invention relates to a torsion and / or tension and / or pressure textile sensor. The textile sensor is a resistive-type sensor consisting of: at least one base layer of fabric (1) comprising any composition and / or mixture and produced using any technique; optionally a surface treatment (2) in order to render the surface of the fabric (1) more uniform; a single conductive layer (3) having tracks distributed geometrically such as to define areas (31) sensitive to stresses from conductive fluids and an encapsulation and protection layer (4) on the conductive layer (3); optionally an upper fabric layer (5); and a least one signal converter (7) which is connected to the tracks, such that when one of the above-mentioned areas (31) is subjected to pressure, tension or torsion a large variation in the resistance of said track is produced, which can be detected by the converter (7). The sensor optionally includes an imprint (6) defining the aforementioned areas (31) on the outer face of either of the fabric layers (1,5).

Owner:FUNDACIO PRIVADA PER A LA INNOVACIO TEXTIL DIGUALADA

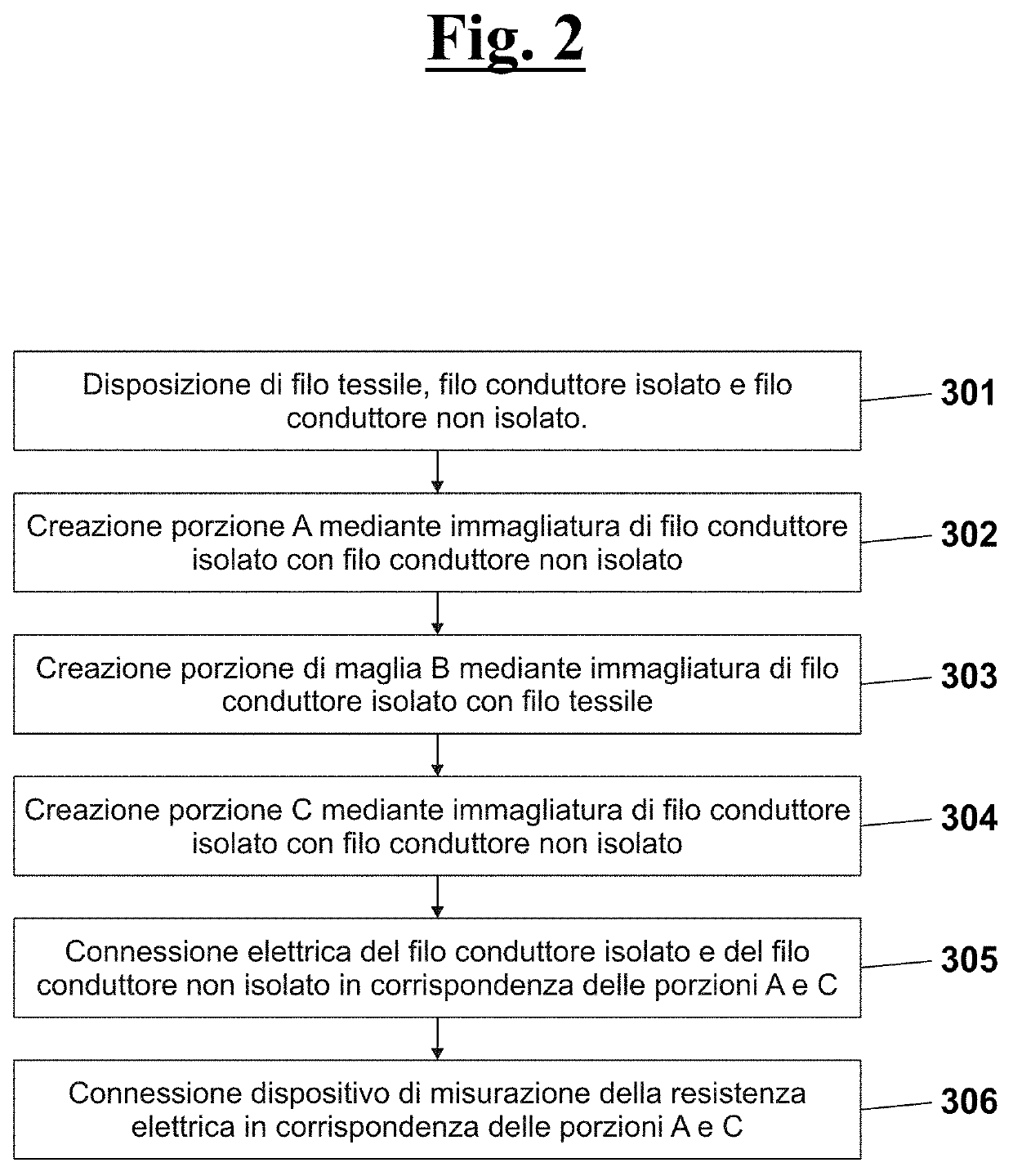

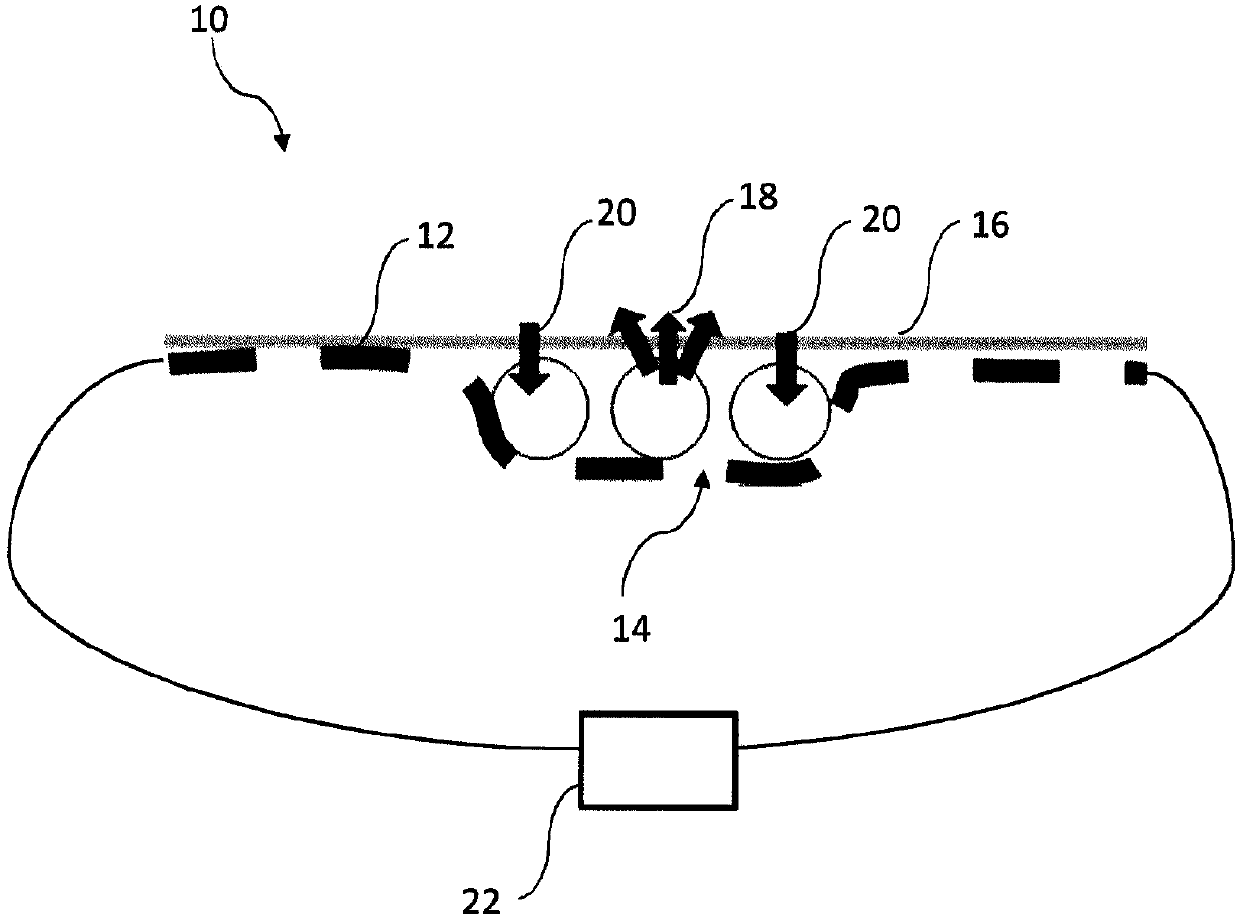

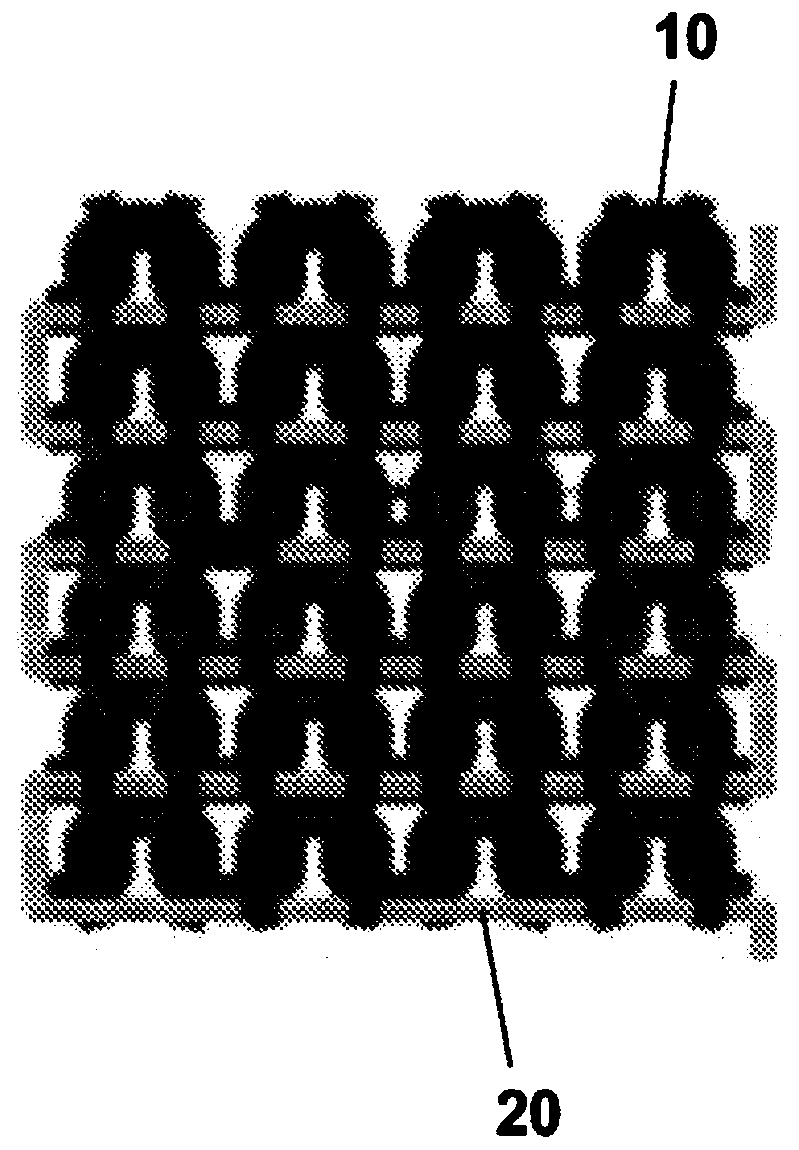

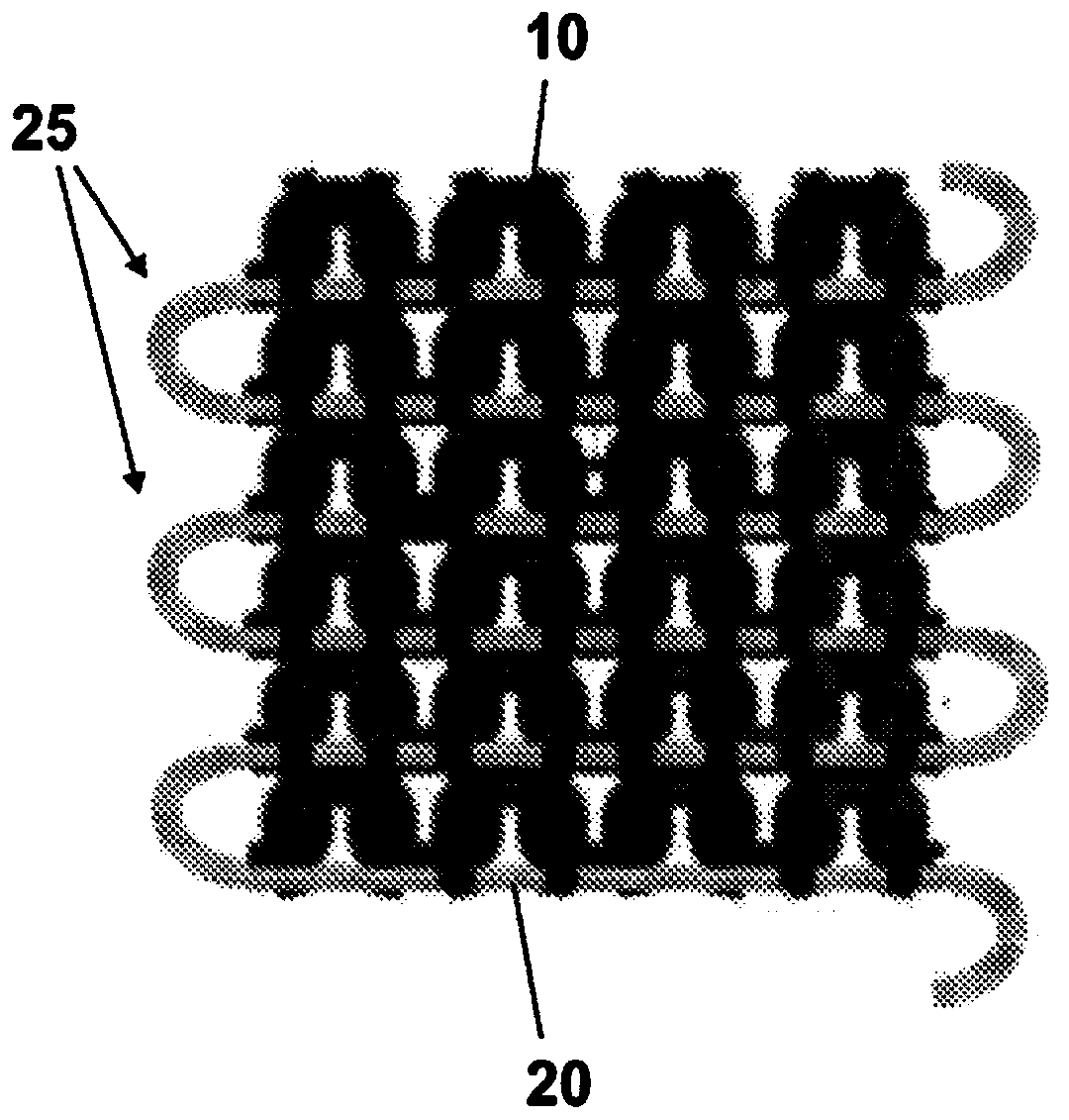

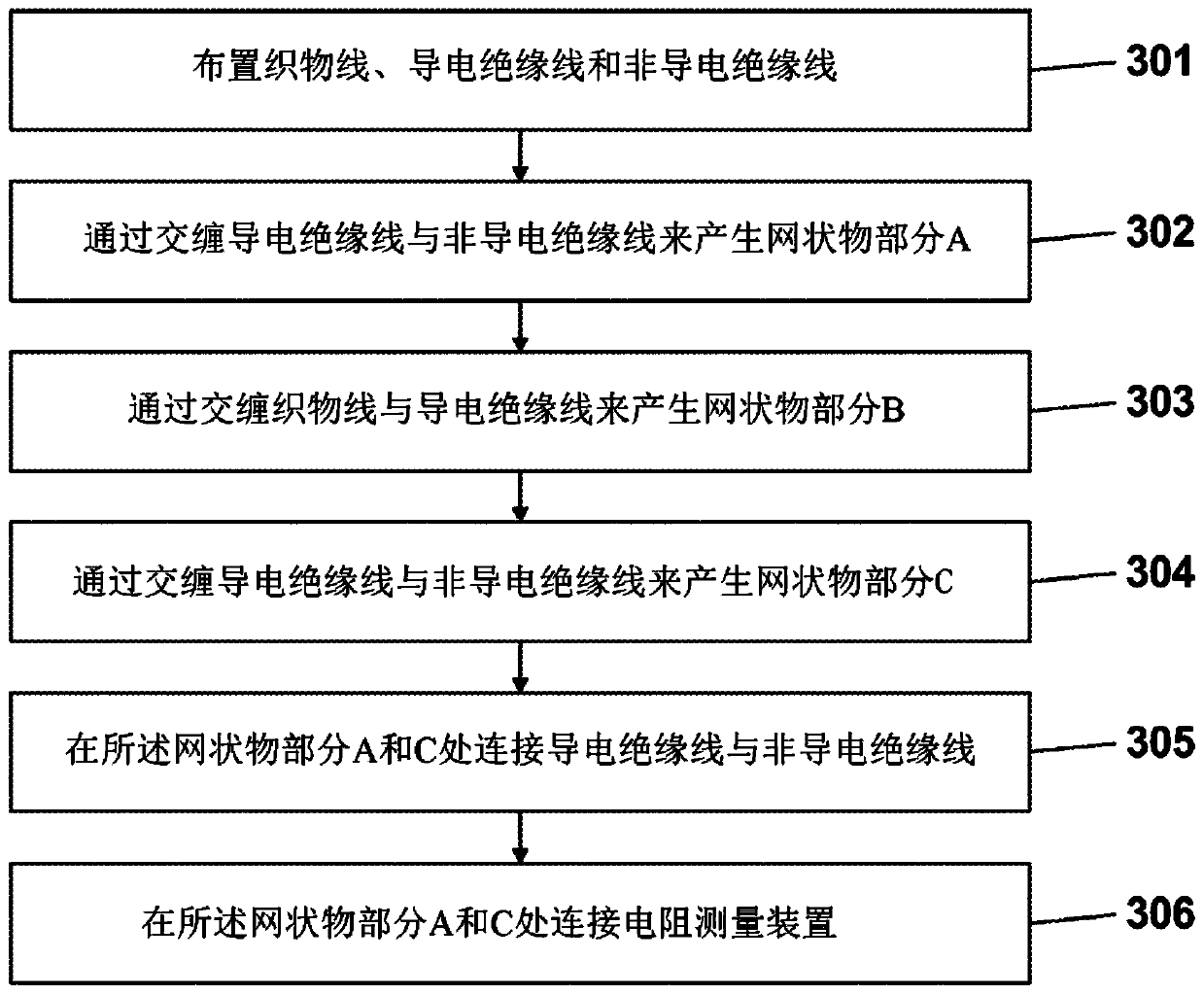

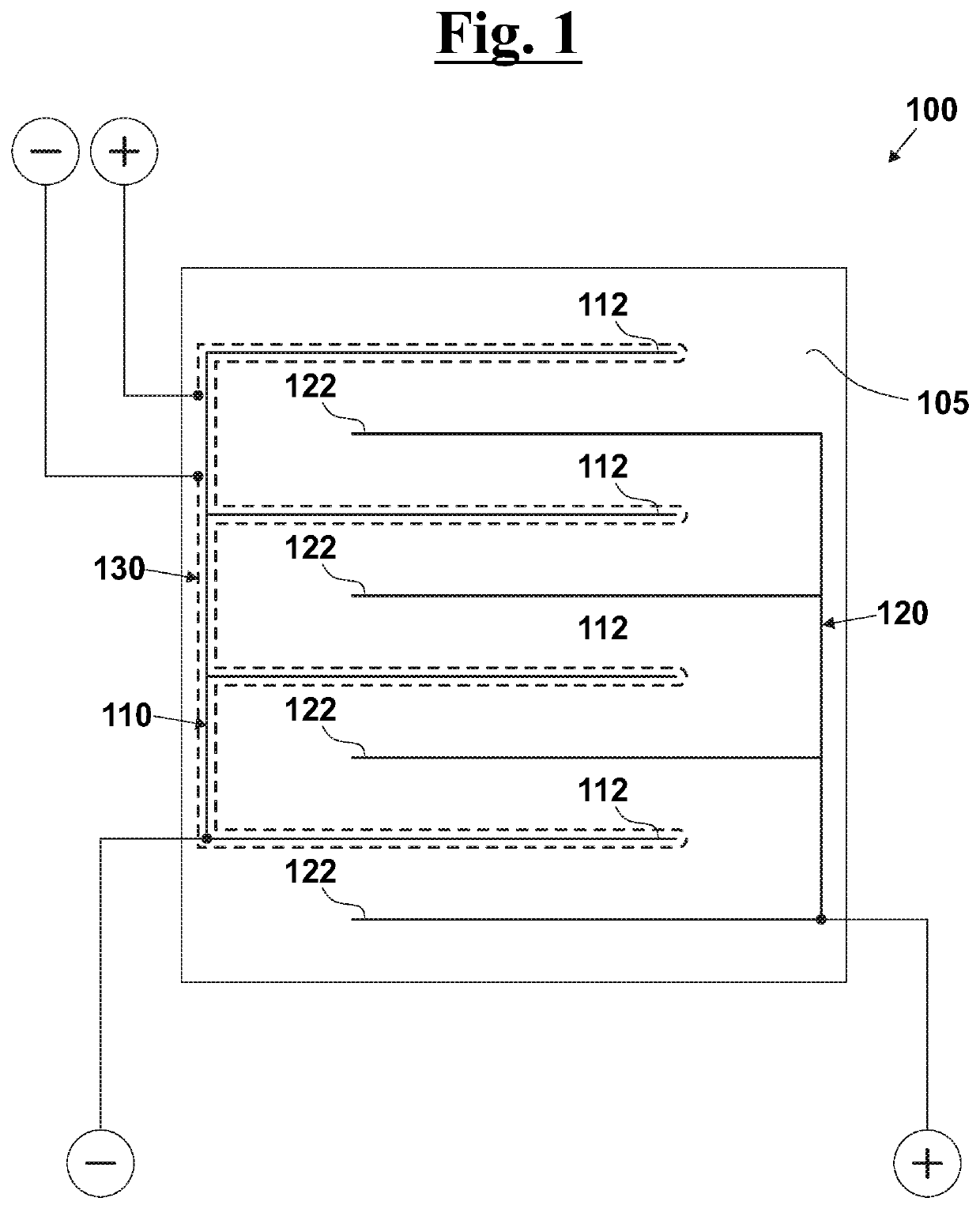

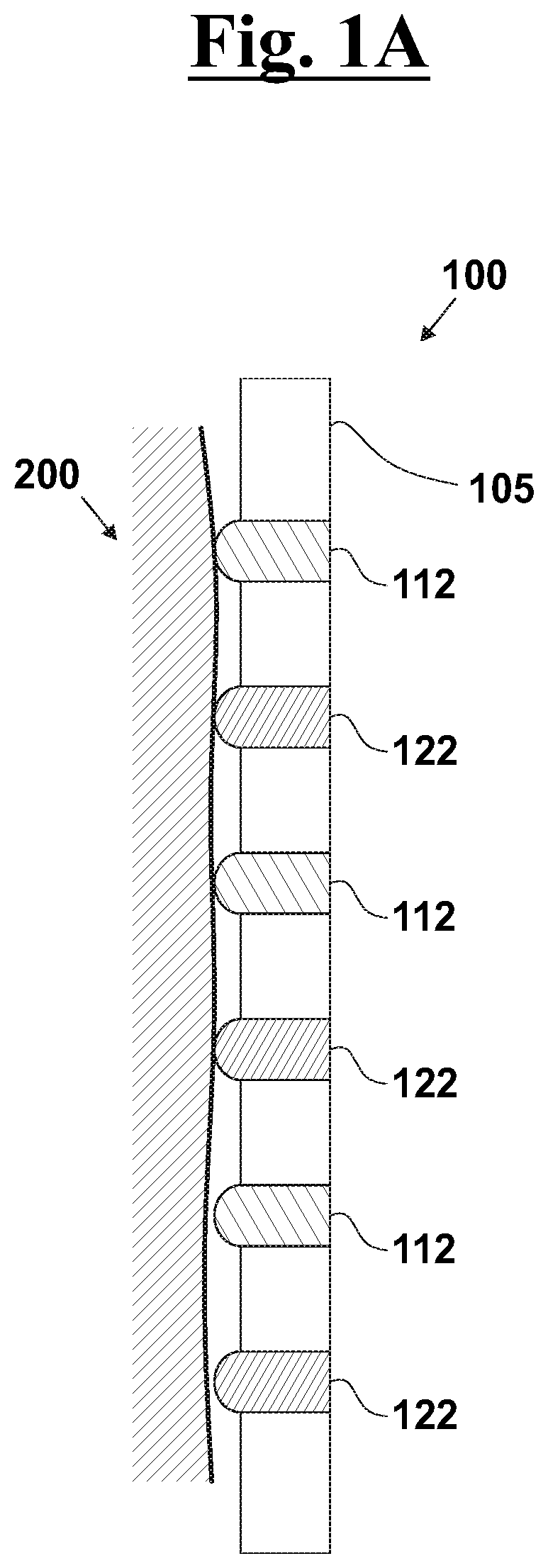

Method for producing a textile sensor

ActiveUS20190353533A1Increase the lengthLow sectionThermometer detailsOrnamental textile articlesElectricityElectrical resistance and conductance

A method for manufacturing a textile temperature sensor, including arranging a linear knitting machine having a first thread-guide and a second thread-guide; arranging a conductive insulated wire on the first thread-guide; meshing the conductive insulated wire for making a mesh portion B having a nonconductive surface; arranging an electric resistance measuring device configured to measure a variation of electric resistance, the electric resistance being a function of the temperature; the measuring device phase of the electric resistance including a first electric cable and a second electric cable; electric connection of the first electric cable to the first end and of the second electric cable to the second end; and arranging a control unit arranged to receive from the device the variation of electric resistance in order to calculate excursions of the temperature at the lead wire.

Owner:KNITRONIX SRL

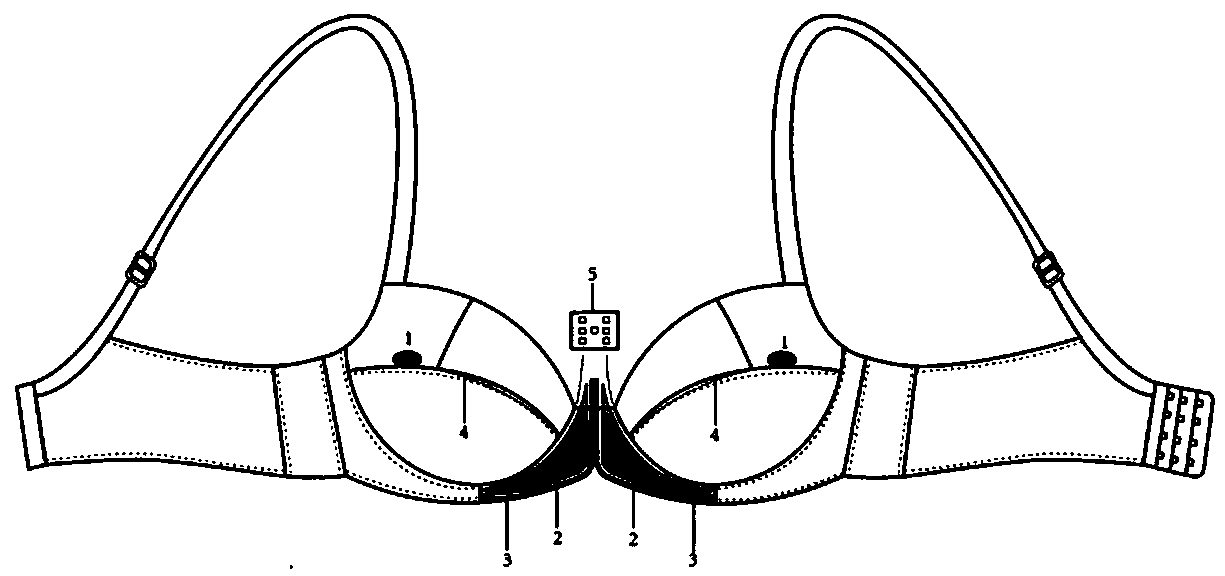

Multi-physiological-parameter monitoring intelligent bras integrated with textile sensor and manufacturing method of multi-physiological-parameter monitoring intelligent bras

InactiveCN108652093ASensorless performanceWith sensor performanceBrassieresRespiratory organ evaluationTextile sensorsEngineering

The invention provides a pair of multi-physiological-parameter monitoring intelligent bras integrated with a textile sensor and a manufacturing method of the multi-physiological-parameter monitoring intelligent bras. The bras comprise bra bodies, a micro data processing device, textile structure flexible electrocardio-electrodes, a textile structure flexible breathing electrode and a textile structure temperature sensor which are connected, wherein the micro data processing device is separately connected with the textile structure flexible electrocardio-electrodes, the textile structure flexible breathing electrode and the textile structure temperature sensor; the micro data processing device is detachably mounted on a heart position of the bra bodies; the textile structure flexible electrocardio-electrodes are arranged on cotton cloth at the inner side of cups of the bra bodies; the textile structure flexible breathing electrode is arranged on a rubber band of lower parts of the bra bodies; and the textile structure temperature sensor is arranged on shaped gauze of the inner layer of the heart of the bra bodies, and is in direct contact with wearer skin. According to the bras provided by the invention, conductive yarns are directly woven or ambroidered into fabric, does not need conductive treatment, so that the bras have the advantages of no coatings, softness, skin friendliness and the like.

Owner:MINJIANG UNIV

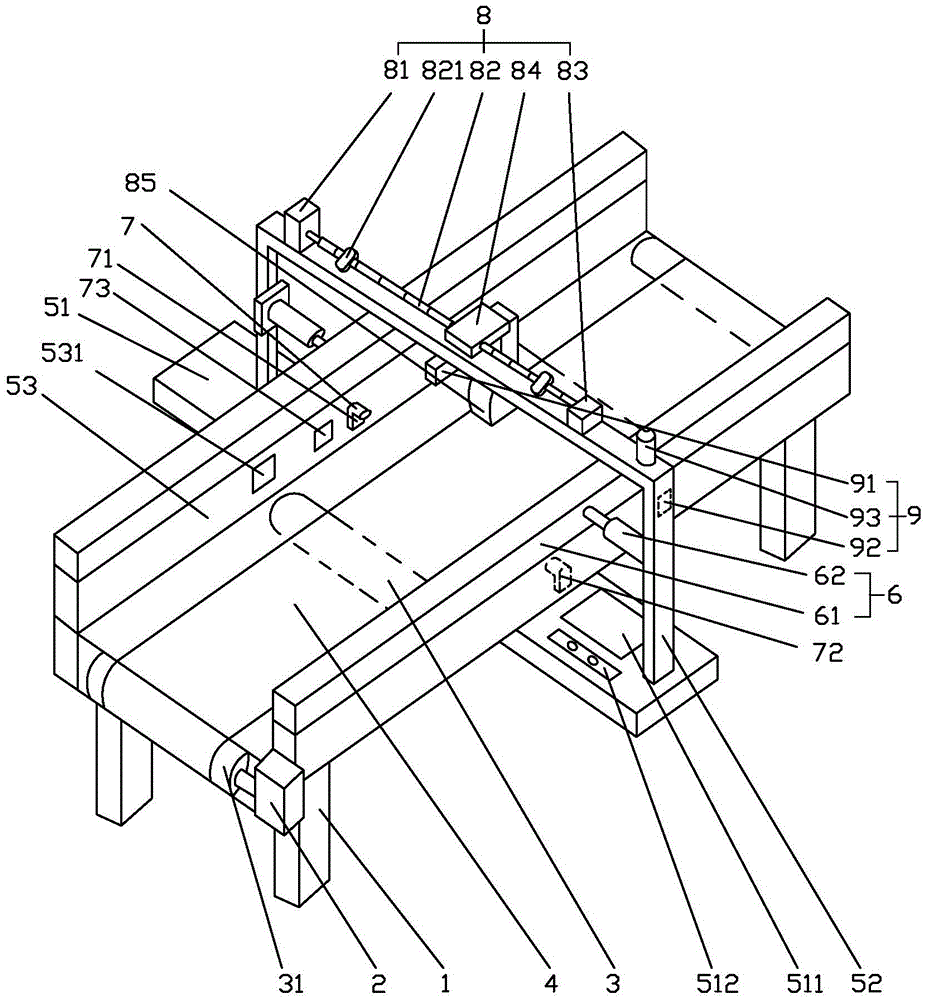

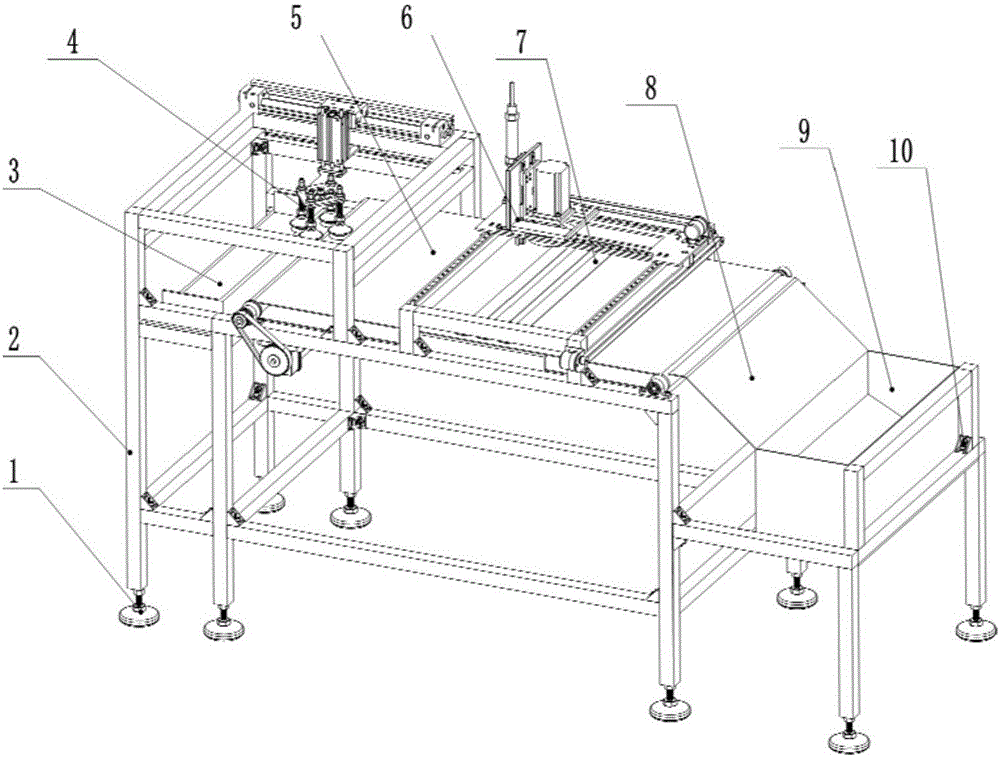

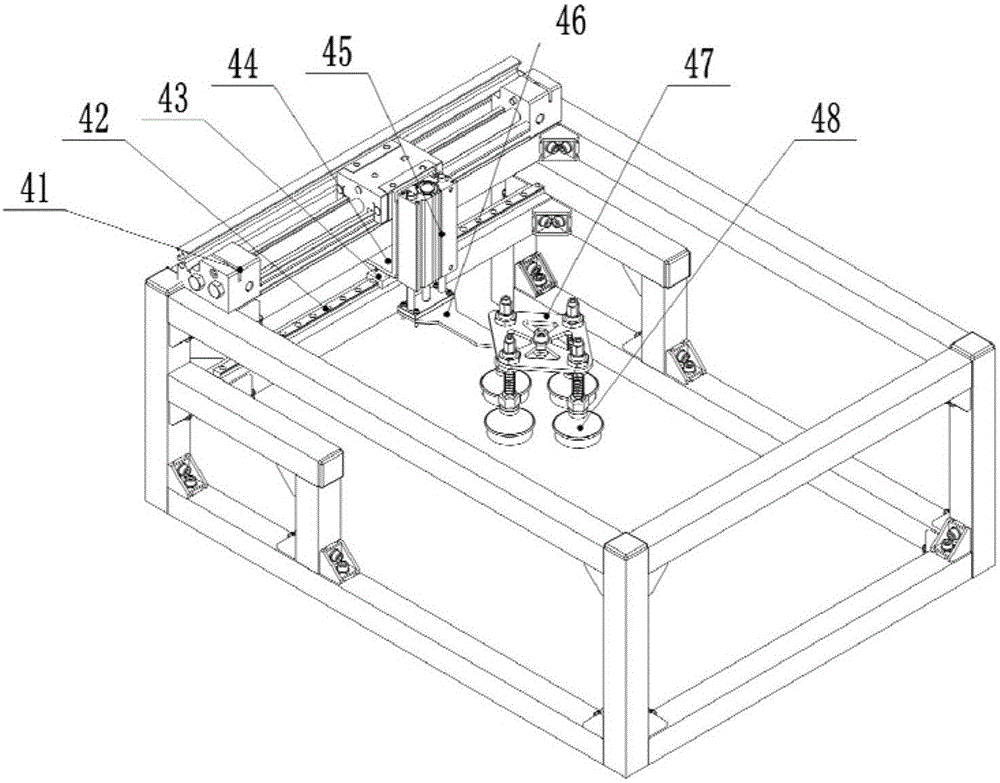

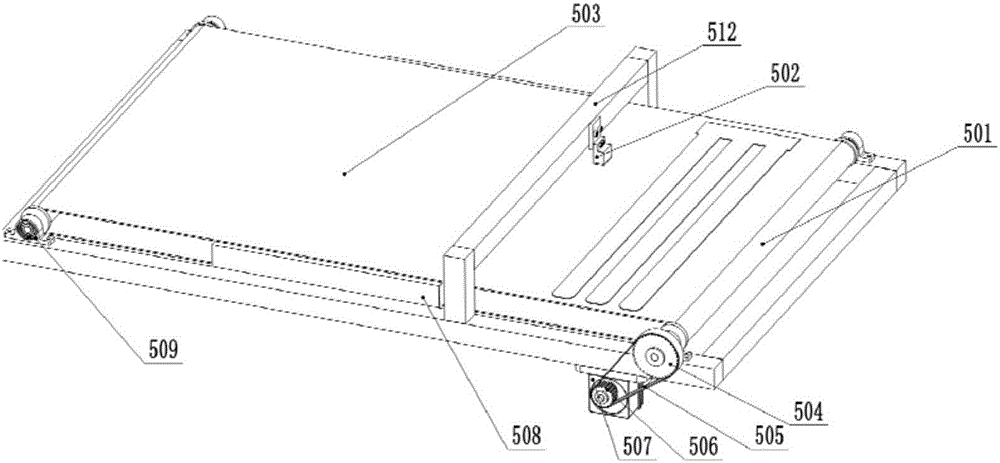

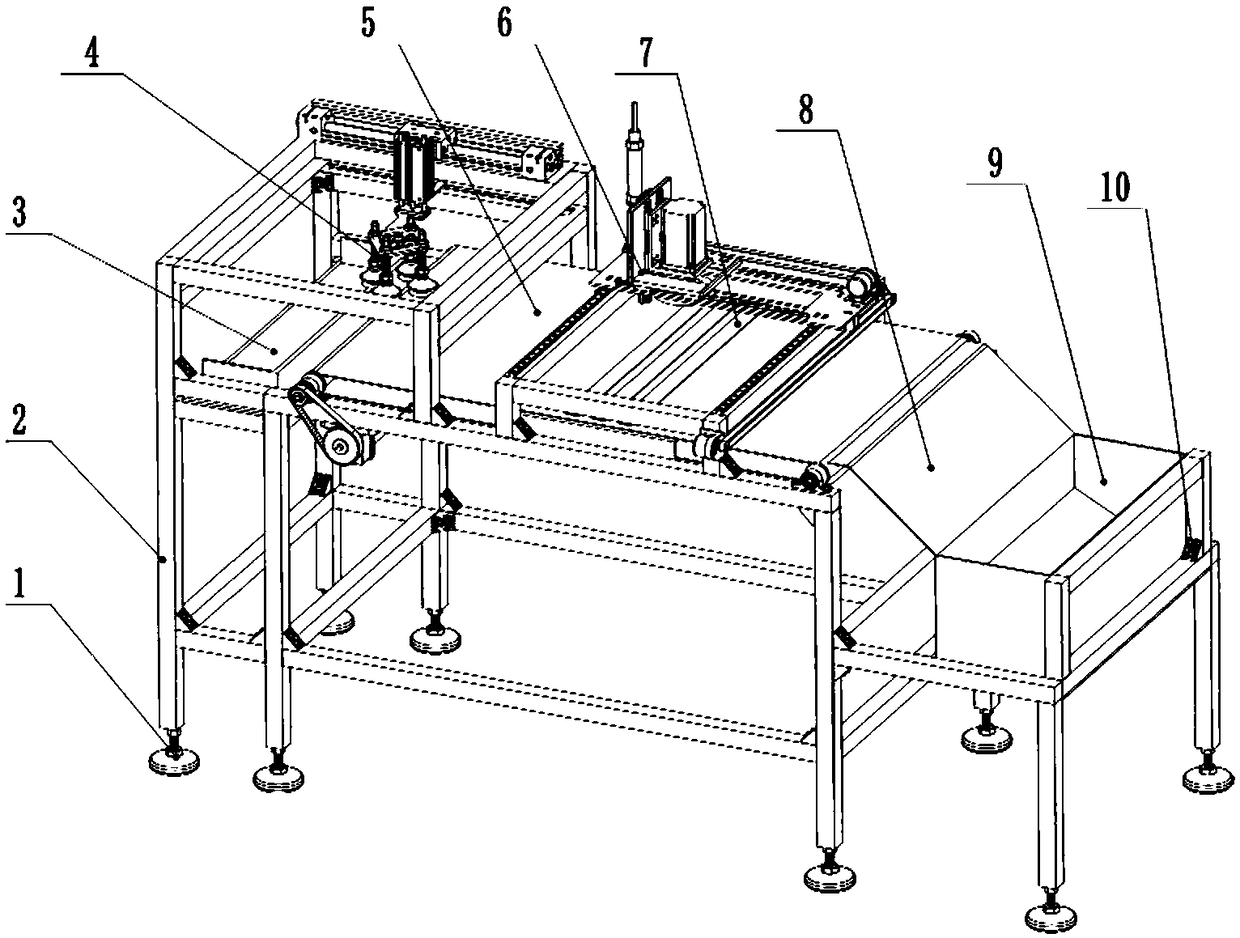

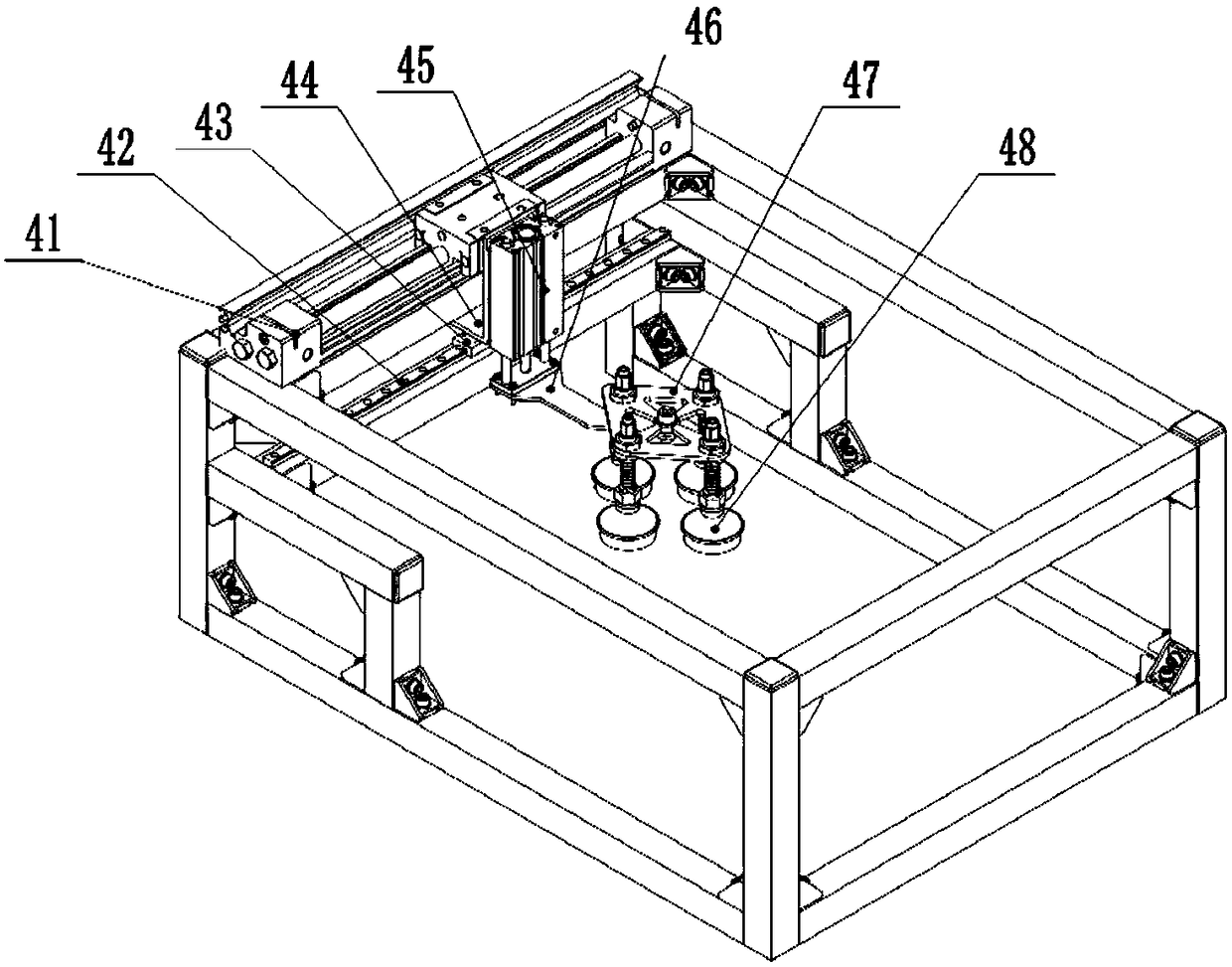

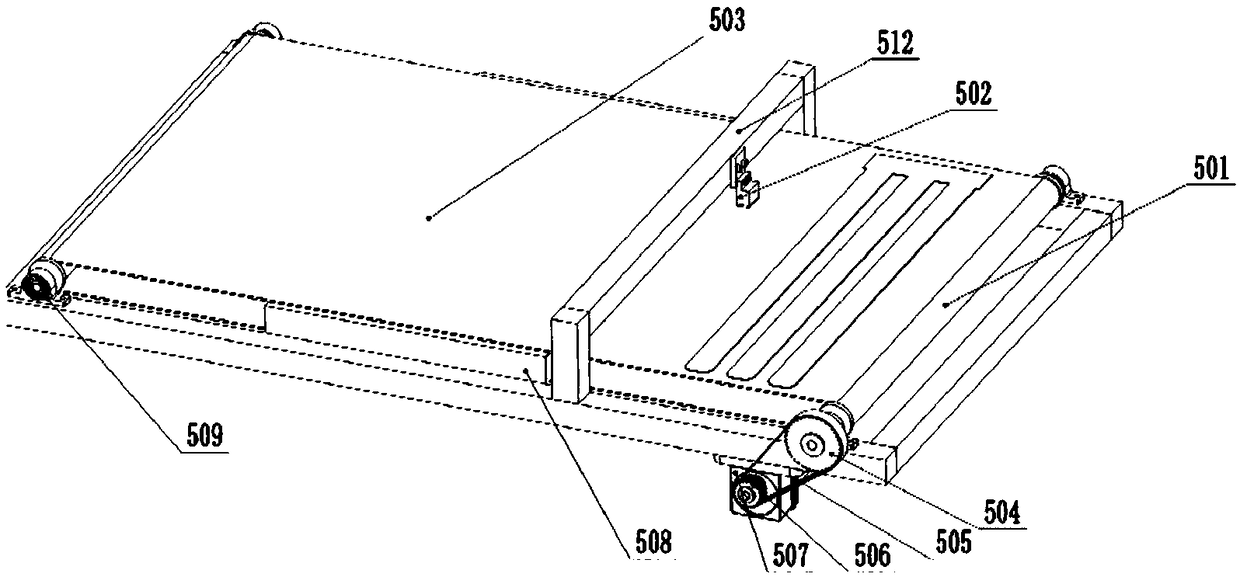

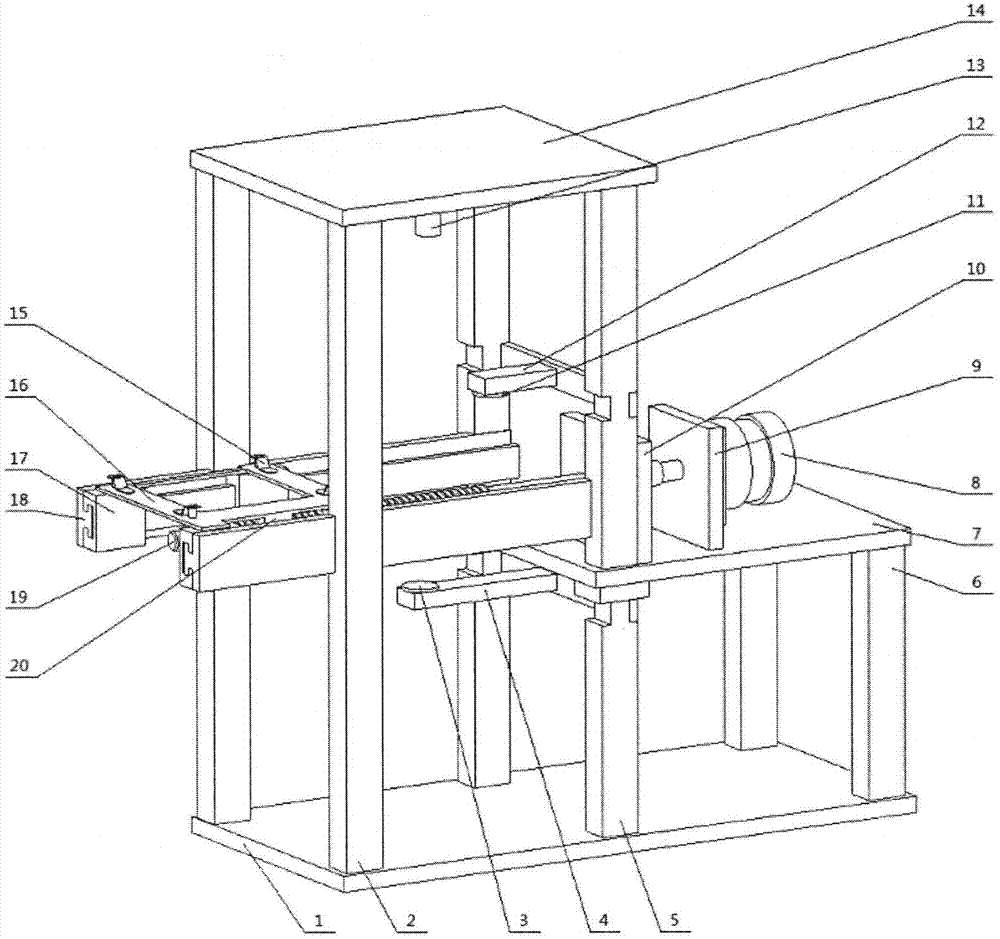

Automatic cleaning machine and method for textile sensor metal comb

ActiveCN106695501AImprove cleaning efficiencyEasy to cleanGrinding machinesGrinding feedersTextile sensorsModular design

The invention discloses an automatic cleaning machine and method for a textile sensor metal comb. The automatic cleaning machine comprises a feeding box, a feeding system, a conveying system, a cleaning and polishing system, a discharging box, a bracket, fixing corner pieces and adjusting feet. The automatic cleaning machine and method are suitable for polishing and cleaning of the textile sensor knitted belt laser cutting fixture metal comb. Modular design is adopted. The cleaning machine is mainly divided into the feeding system, the conveying system and the cleaning and polishing system. The main body of the cleaning machine for the metal comb is fixed to the bracket. The to-be-cleaned metal comb is placed in the feeding box, carried onto a conveying belt through the feeding system and ensured to be single; the metal comb is conveyed to the designated position through the conveying belt and fixed through an electromagnet; polishing and cleaning are started; and after cleaning is completed, the metal comb is conveyed to the metal comb discharging box through the conveying belt. The metal comb automatic cleaning method provided by the invention replaces an existing worker manual cleaning working mode, the working environment of metal comb cleaning workers is improved, and the cleaning efficiency is improved.

Owner:ZHEJIANG UNIV

Independent wearable health monitoring system adapted to interface with a treatment device

Owner:HEALTHWATCH LTD

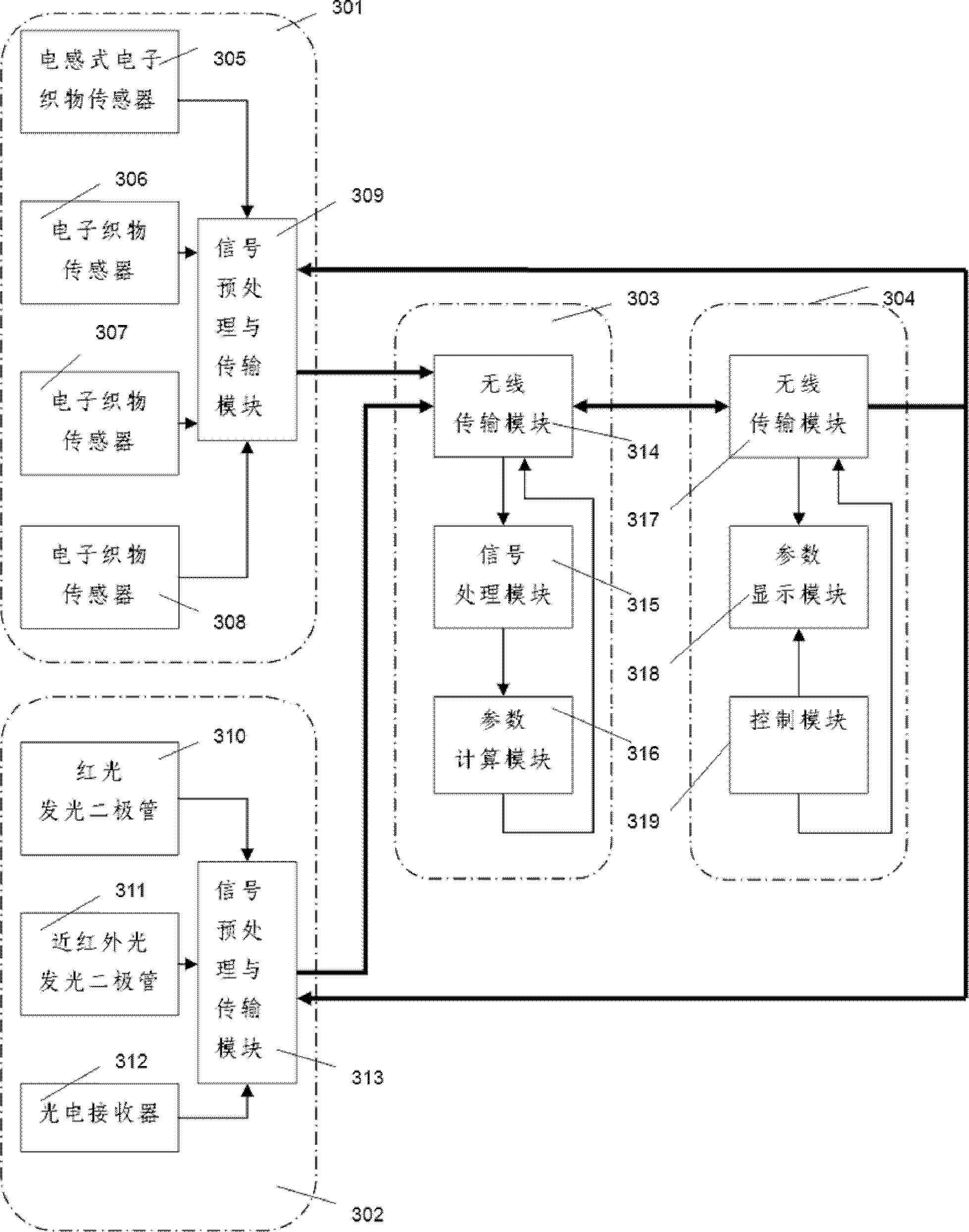

Combined textile pressure and optic sensor

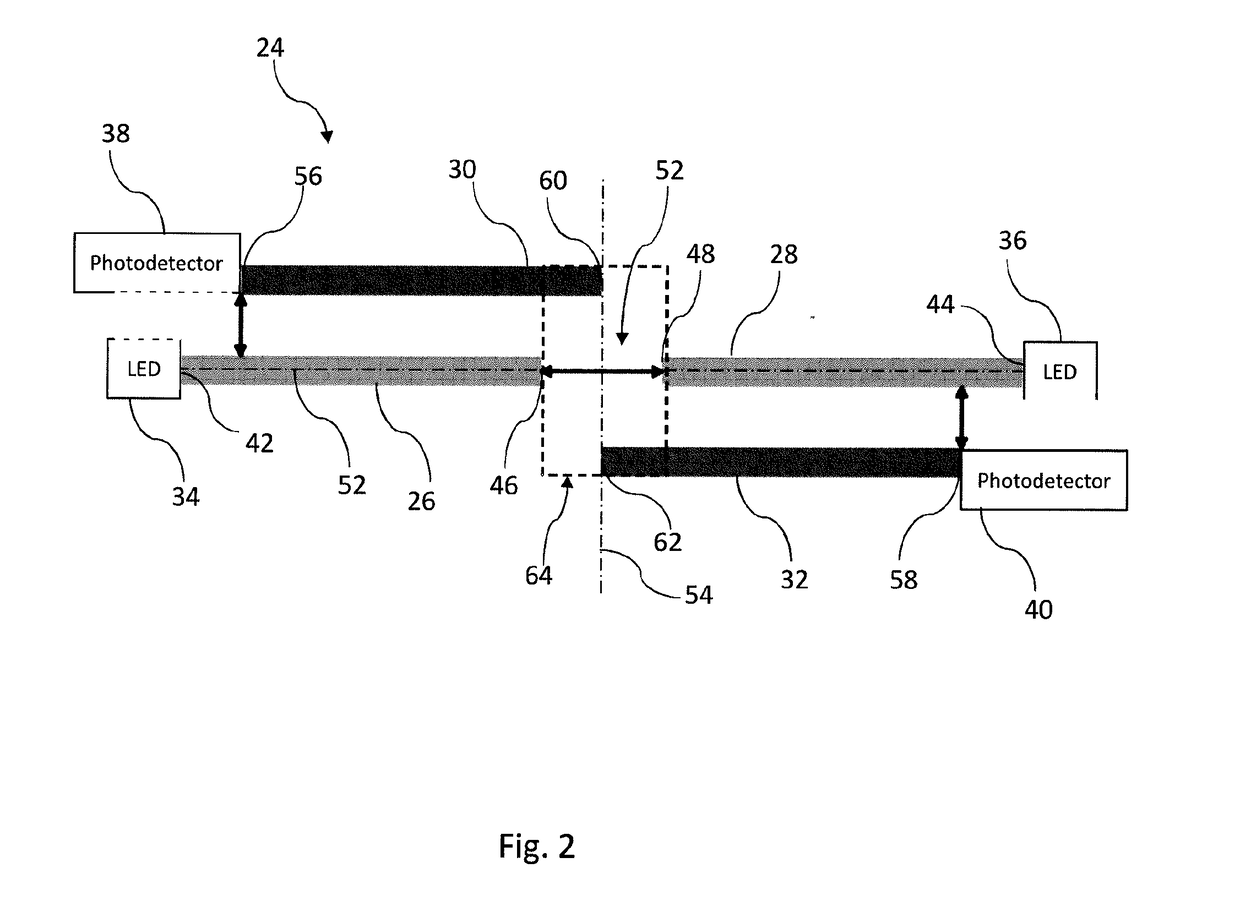

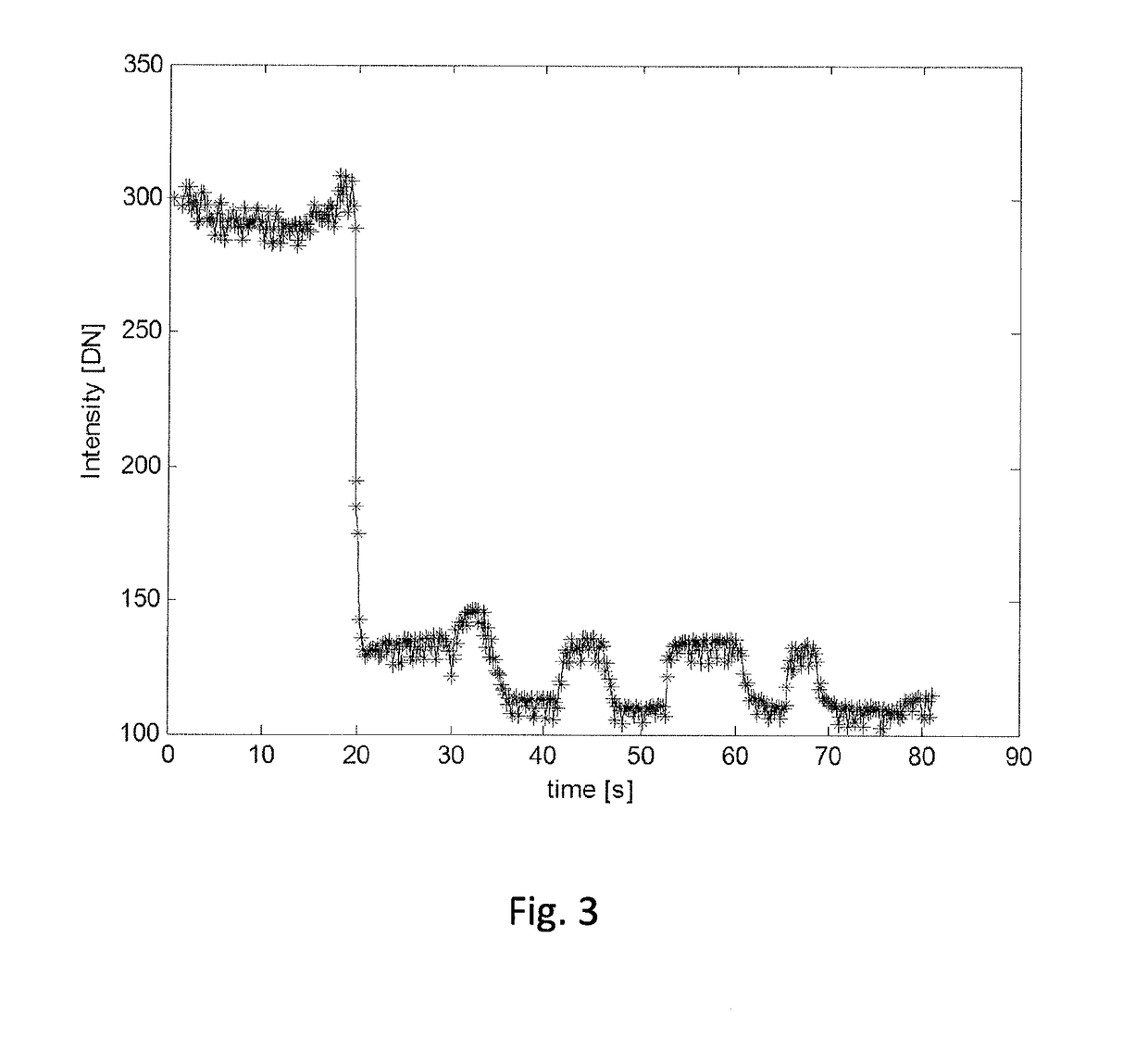

InactiveUS20190069785A1Remove Motion ArtifactsEliminate relative motionWeft knittingOrnamental textile articlesTextile sensorsEngineering

A combined sensor adapted to measure at least one medical or clinical sign is provided. The combined sensor comprises a textile sensor configured so as to determine pressure applied to the combined sensor; and an optical sensor. The optical sensor typically comprises at least one fibre-optic sensor (FOS) and may function as a photoplethysmography (PPG) sensor, optionally a reflectance mode photoplethysmography (PPG) sensor. The combined sensor is able to eliminate motion artefacts caused by movement of a subject wearing the sensor thereby facilitating long-term ambulatory monitoring of subjects.

Owner:FOOTFALLS & HEARTBEATS (UK) LTD +1

Combined textile pressure and optic sensor

A combined sensor adapted to measure at least one medical or clinical sign is provided. The combined sensor comprises a textile sensor configured so as to determine pressure applied to the combined sensor; and an optical sensor. The optical sensor typically comprises at least one fibre- optic sensor (FOS) and may function as a photoplethysmography (PPG) sensor, optionally a reflectance mode photoplethysmography (PPG) sensor. The combined sensor is able to eliminate motion artefacts caused by movement of a subject wearing the sensor thereby facilitating long-term ambulatory monitoring of subjects.

Owner:FOOTFALLS & HEARTBEATS (UK) LTD +1

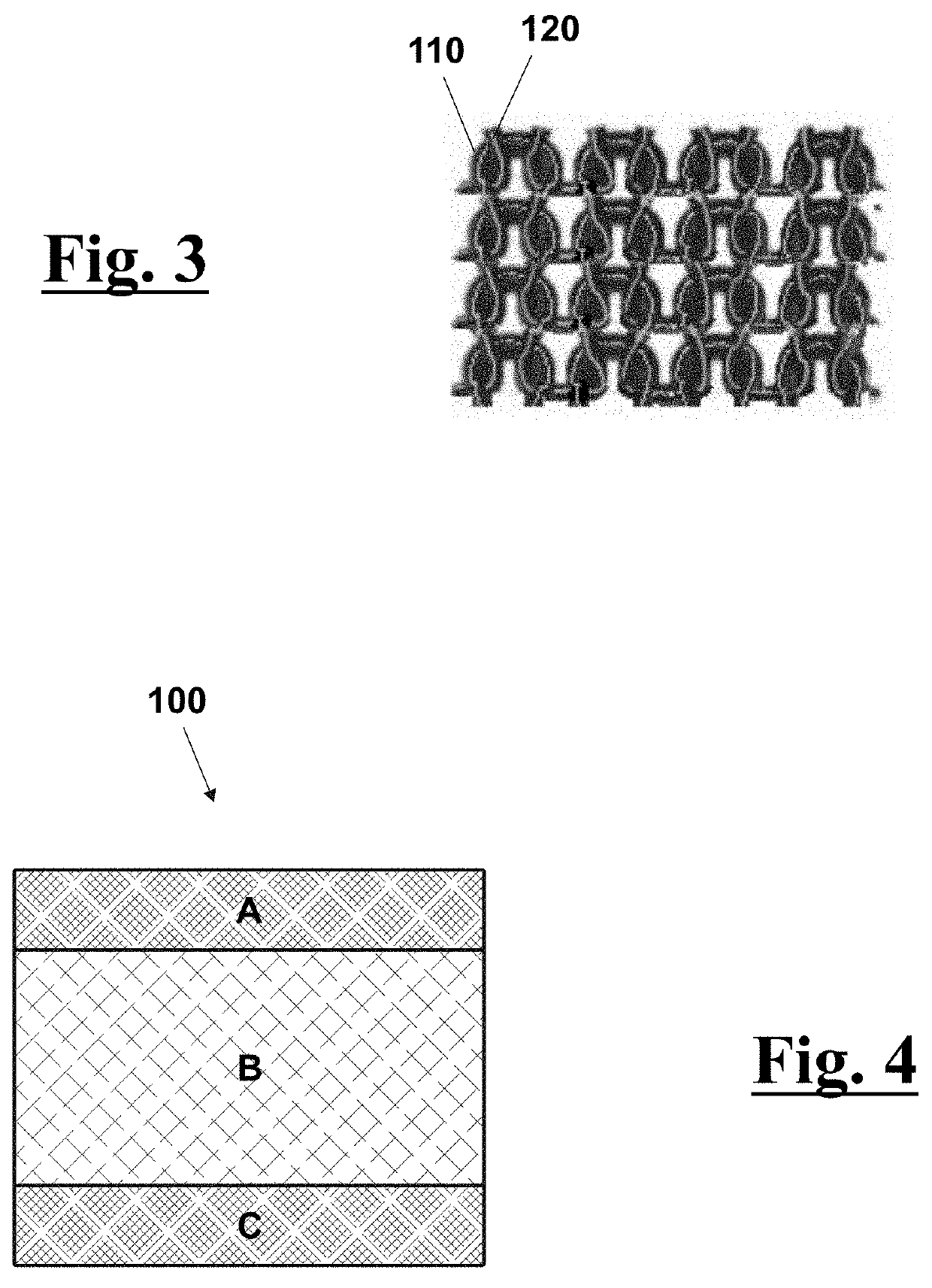

Method for producing a textile sensor

InactiveCN109716082AThermometer detailsWeft knittingElectrical resistance and conductanceElectricity

The invention provides a method for manufacturing a textile temperature sensor (100). The method comprises the steps of arranging a linear knitting machine comprising at least one first thread-guide and a second thread-guide; arranging a conductive insulated wire (120) on the first thread-guide, said conductive insulated wire (120) having a first end (121) and a second end (122); meshing the conductive insulated wire (120) for making a mesh portion B having not conductive surface. The method comprises then the steps of arranging an electric resistance measuring device configured to measure a variation of electric resistance R(T), said electric resistance R(T) being function of the temperature T, said step of measuring device phase of the electric resistance comprising a first electric cable (201) and a second electric cable (202); electric connection of the first electric cable (201) to the first end (121) and of the second electric cable (202) to the second end (122); arranging a control unit arranged to receive from the device the variation of electric resistance R(T) in order to calculate excursions of temperature T at the lead wire (120).

Owner:PLUG & WEAR SRL

Large scale manufacturing of hybrid nanostructured textile sensors

ActiveUS20180080126A9Material nanotechnologyLiquid surface applicatorsMicro structureTextile sensors

A process for the large-scale manufacturing vertically standing hybrid nanometer scale structures of different geometries including fractal architecture of nanostructure within a nano / micro structures made of flexible materials, on a flexible substrate including textiles is disclosed. The structures increase the surface area of the substrate. The structures maybe coated with materials that are sensitive to various physical parameters or chemicals such as but not limited to humidity, pressure, atmospheric pressure, and electromagnetic signals originating from biological or non-biological sources, volatile gases and pH. The increased surface area achieved through the disclosed process is intended to improve the sensitivity of the sensors formed by coating of the structure and substrate with a material which can be used to sense physical parameters and chemicals as listed previously. An embodiment with the structures on a textile substrate coated with a conductive, malleable and bio-compatible sensing material for use as a biopotential measurement electrode is provided.

Owner:NANOWEAR

Multifunctional textile sensor

ActiveUS10701801B2Maintain comfort and seamless and mechanical flexibilityPrinted circuit assemblingPrinted circuit aspectsTextile sensorsSensing applications

Owner:CONTINENTAL IND TEXTIL DO AVE SA

Textile sensor for the detection of liquids and temperature, and method of making same

PendingUS20220307166A1Good extensibilityIncrease flexibilityWeft knittingOrnamental textile articlesElectrical resistance and conductanceTextile sensors

A textile device for detecting liquids comprising a matrix fabric obtained by knitting, a first non-insulated conductive wire and a second non-insulated conductive wire knitted with the matrix fabric, a source of electric energy connected to the non-insulated conductive wires in order to create a first electric circuit and to have a potential difference between the non-insulated conductive wires, an electrical resistance measuring device configured to measure the electric resistance R in the first electric circuit. The textile device is configured in such a way that, when the non-insulated conductive wires electrically connect by means of a liquid, the electrical resistance measuring system measures a variation of electric resistance R in said first electric circuit. Furthermore, at least one insulated conductive wire is provided connected to a source of electric energy in order to create a second electric circuit.

Owner:KNITRONIX SRL

A textile sensor metal comb automatic cleaning machine and method thereof

ActiveCN106695501BImprove cleaning efficiencyEasy to cleanGrinding machinesGrinding feedersTextile sensorsModular design

The invention discloses an automatic cleaning machine and method for a textile sensor metal comb. The automatic cleaning machine comprises a feeding box, a feeding system, a conveying system, a cleaning and polishing system, a discharging box, a bracket, fixing corner pieces and adjusting feet. The automatic cleaning machine and method are suitable for polishing and cleaning of the textile sensor knitted belt laser cutting fixture metal comb. Modular design is adopted. The cleaning machine is mainly divided into the feeding system, the conveying system and the cleaning and polishing system. The main body of the cleaning machine for the metal comb is fixed to the bracket. The to-be-cleaned metal comb is placed in the feeding box, carried onto a conveying belt through the feeding system and ensured to be single; the metal comb is conveyed to the designated position through the conveying belt and fixed through an electromagnet; polishing and cleaning are started; and after cleaning is completed, the metal comb is conveyed to the metal comb discharging box through the conveying belt. The metal comb automatic cleaning method provided by the invention replaces an existing worker manual cleaning working mode, the working environment of metal comb cleaning workers is improved, and the cleaning efficiency is improved.

Owner:ZHEJIANG UNIV

Wearable system capable of continuously measuring multiple physiological parameters based on body sensor network

ActiveCN102283642BAccurate measurementImprove use comfort performanceDiagnostic recording/measuringSensorsTextile sensorsControl signal

The invention relates to a wearable system capable of continuously measuring multiple physiological parameters based on body sensor network. The system comprises at least one physiological signal acquisition module, a signal processing and parameter calculation module, and a signal control and display module, wherein the physiological signal acquisition module is used for acquiring physiological signals; the signal processing and parameter calculation module is used for calculating the physiological parameters according to the physiological signal; the signal control and display module is used for receiving the physiological parameter, displaying the physiological parameter and sending a control signal to control the work of each module; and the sensor adopted by the physiological signal acquisition module is an electronic textile sensor. The physiological parameter measuring system has the advantages of high using comfort and good accuracy.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

A method and device for testing the difference in infrared emission between the front and back of textiles

ActiveCN105181651BQuick measurementSimple structureScattering properties measurementsTransmissivity measurementsTextile sensorsTransmitter

Owner:CHINA JILIANG UNIV

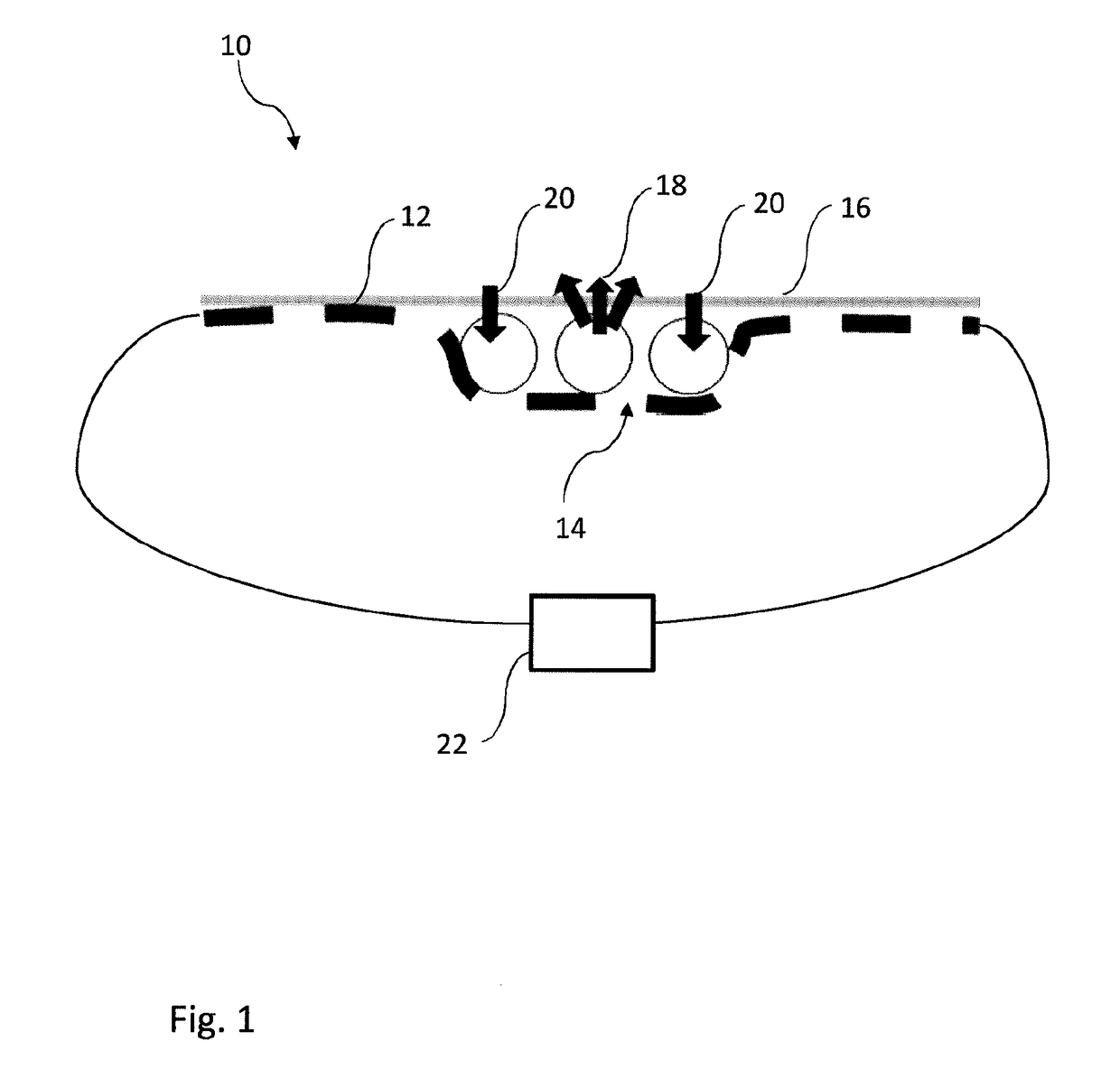

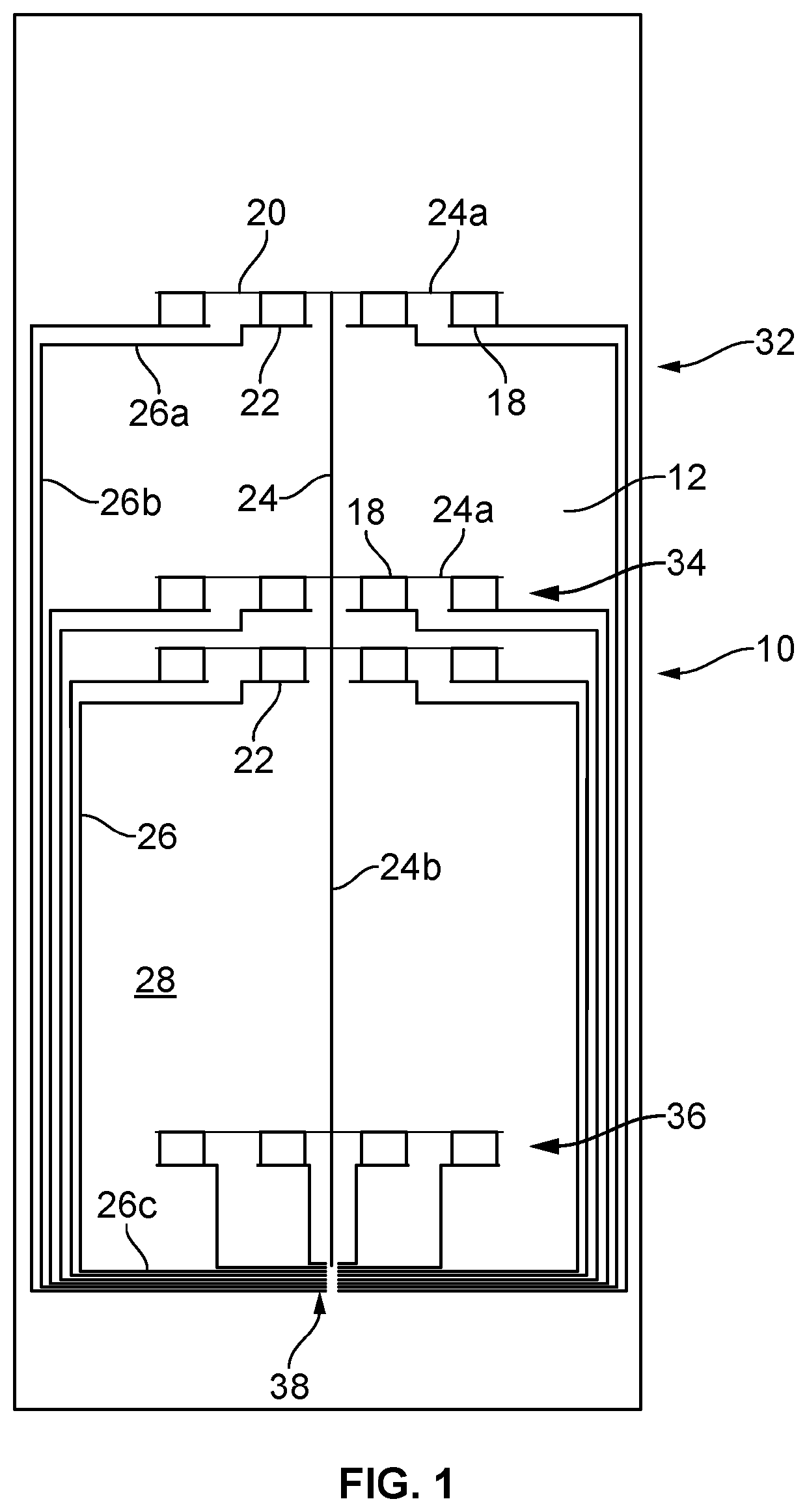

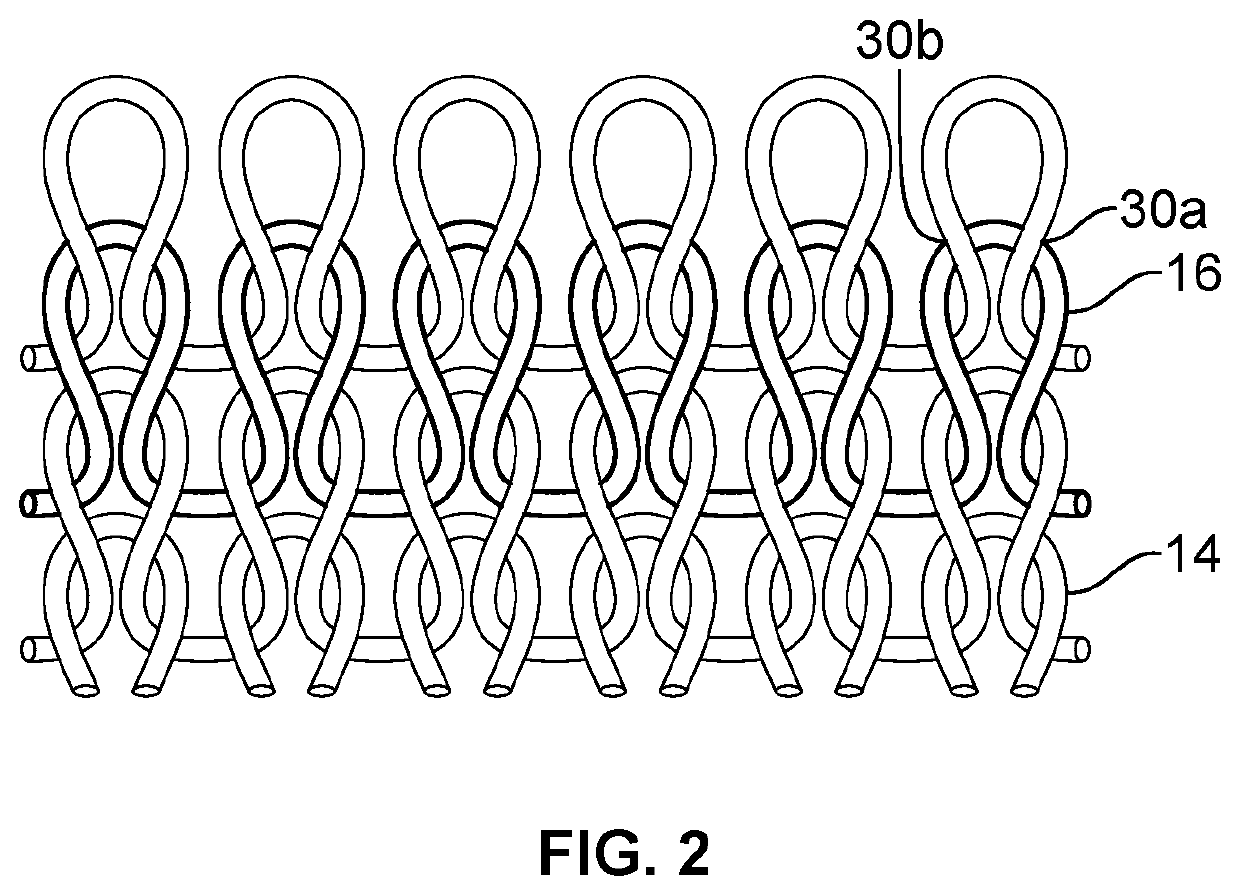

Textile panel and a method of manufacture of a textile panel

The invention provides a textile panel including a knitted or woven textile layer (12) having yarn of a first type (14), and a coating applied to at least one face of the textile layer. The textile layer includes at least one textile sensor (18) formed by an electrically conductive region of the textile layer which includes yarn (16) of a second type incorporated in the knit or weave of the textile layer, the second type of yarn being electrically conductive. The invention also provides a method of manufacturing a textile panel, including knitting or weaving a textile layer (12) using a first type of yarn (14) and a second type of yarn (16), the second type of yarn being incorporated in the knit or weave of the textile layer in at least one predetermined region to form a textile sensor, the method further including applying a coating to the textile layer.

Owner:DARTEX COATINGS LTD

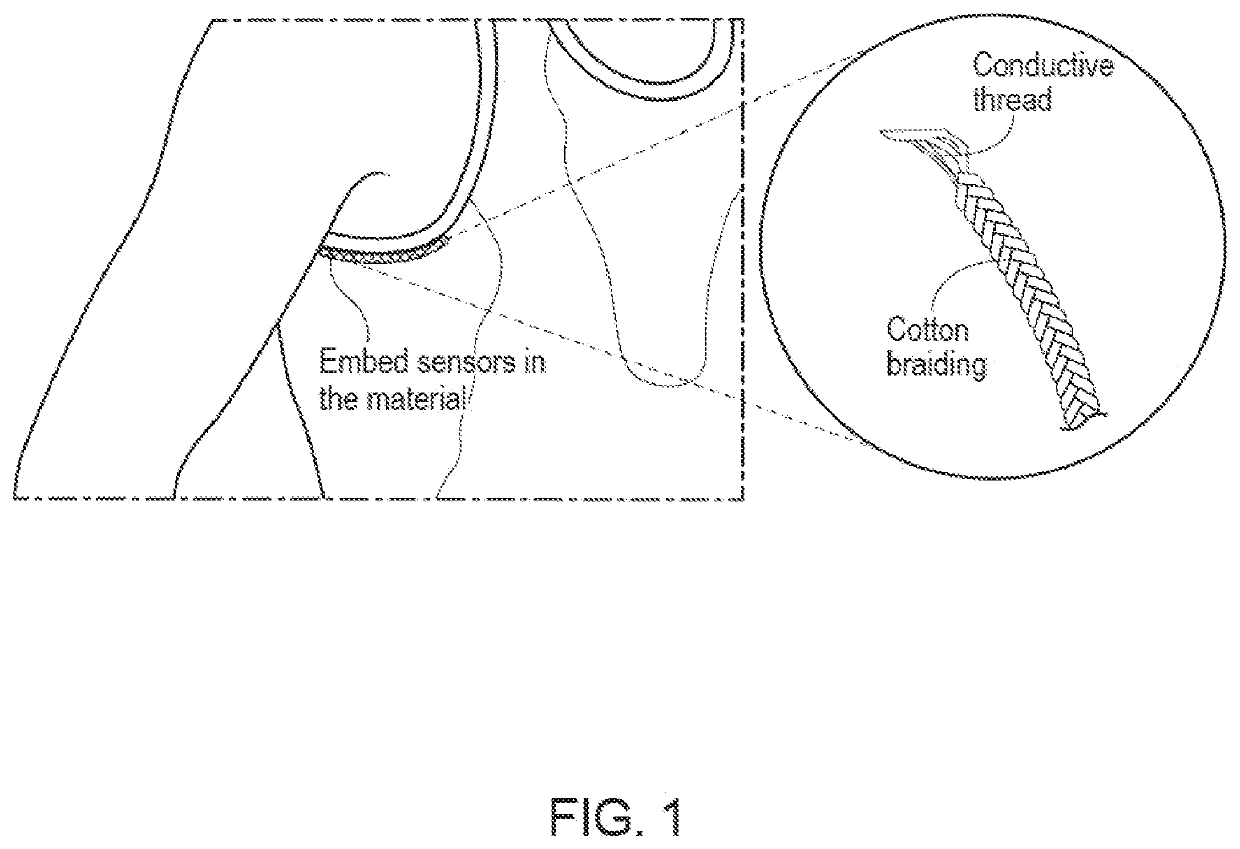

A fabric sensor-based upper limb functional movement monitoring system and method

ActiveCN105266817BImprove stabilityReal-time monitoring of exercise statusDiagnostic recording/measuringSensorsTextile sensorsButton battery

The invention provides a fabric sensor-based upper limb functional movement monitoring system, comprising: a signal generating device, including a conductive fabric with a signal transmission line, the conductive fabric is connected to a button battery; the conductive fabric is closely attached to the elbow joint of the upper limb of the human body, and the upper limb moves Stretching the conductive fabric to change the voltage signal at both ends of the conductive fabric; the signal acquisition and transmission device collects the voltage signal and sends it to the signal receiving and display device; the signal receiving and display device receives the voltage signal, And perform functional movement characterization on it, and at the same time display the functional movement state in real time, save and image the data in real time. The invention also provides a method for monitoring upper limb functional movement based on the fabric sensor. The invention has the advantages of low cost, good stability, high sensitivity and strong adaptability, and at the same time, sensitive elements can be well integrated into daily clothing, which can provide a basis for biomechanical analysis of human upper limb movement.

Owner:ANHUI HENGYI TEXTILE TECH CO LTD

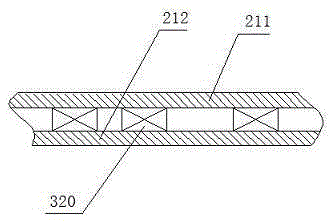

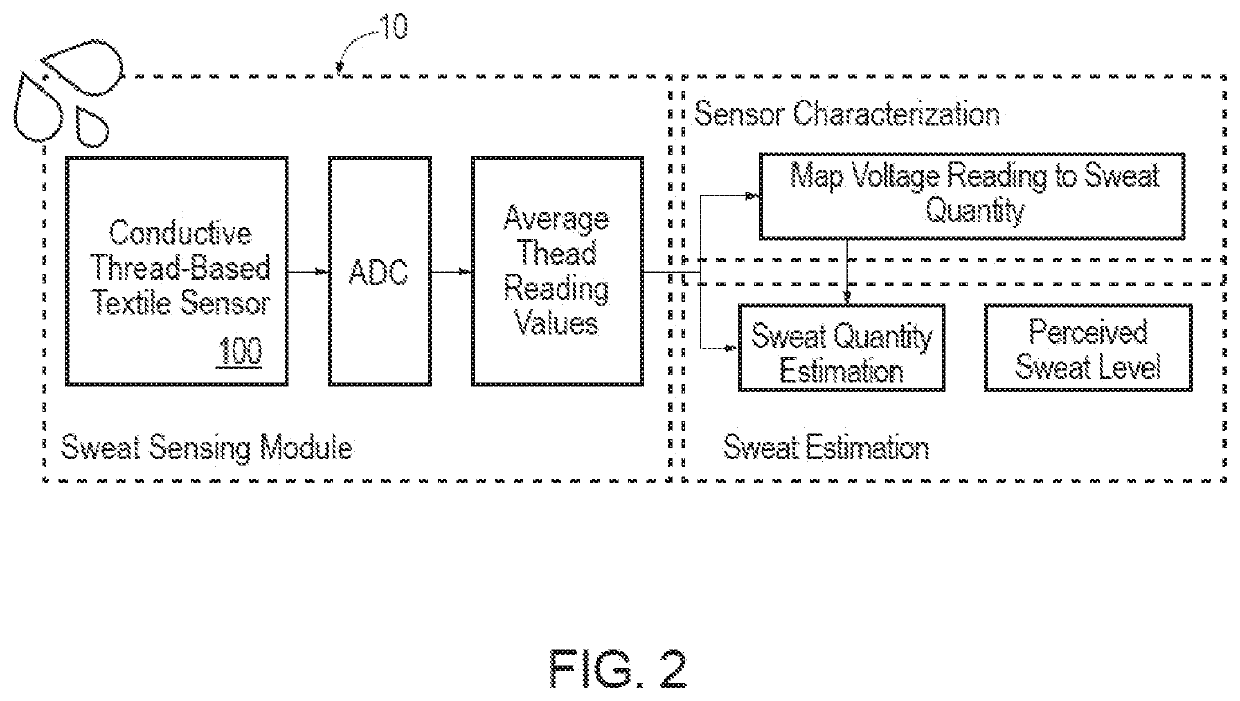

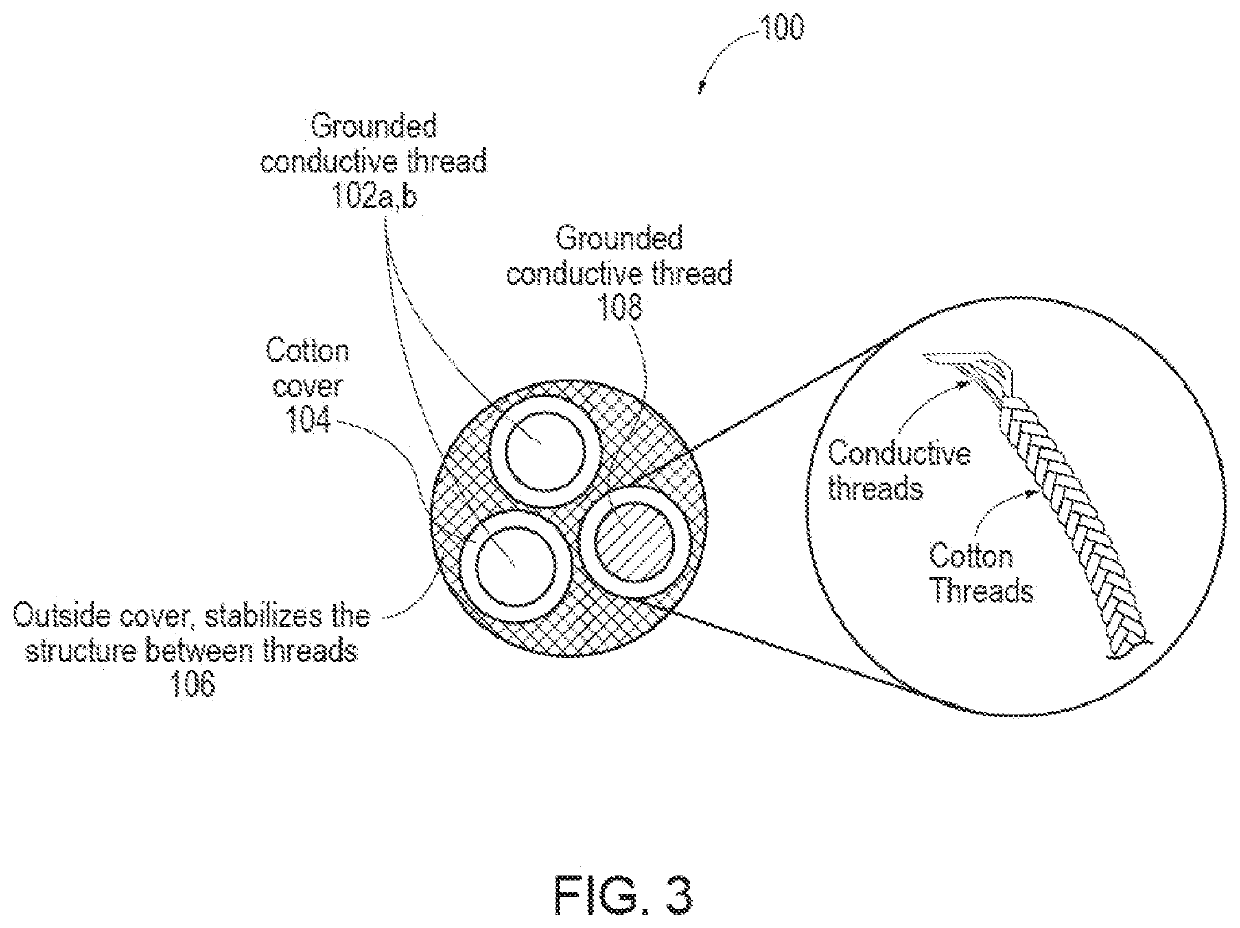

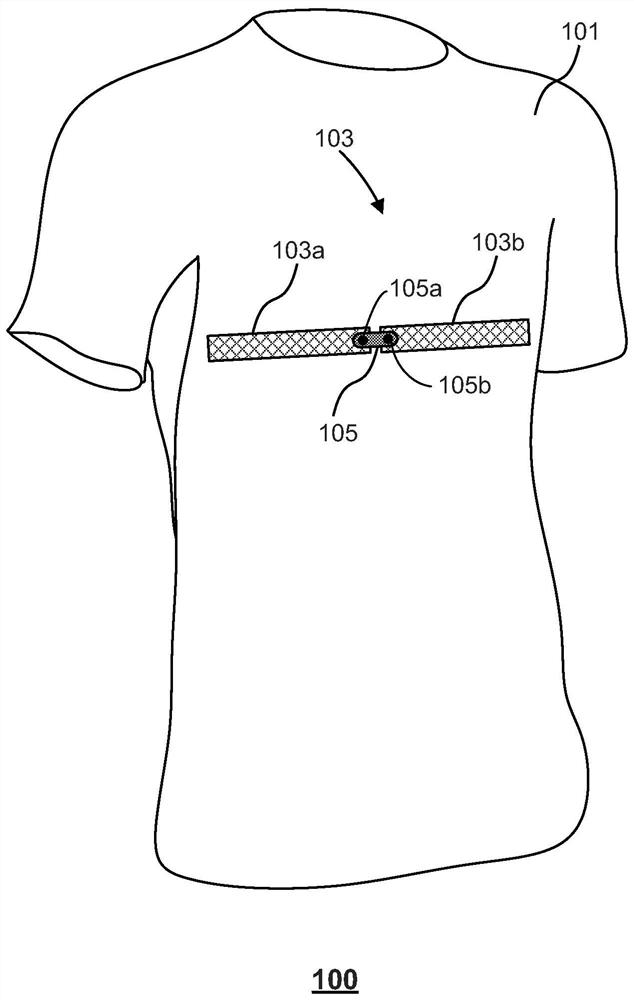

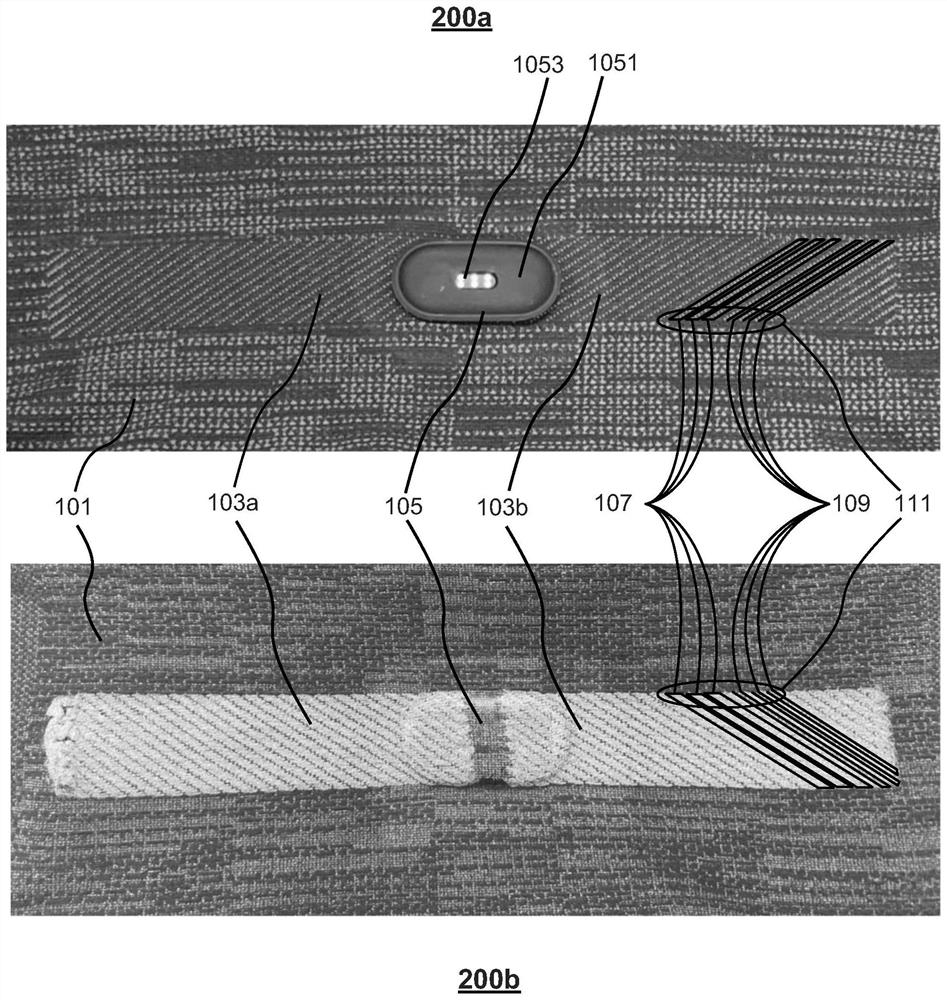

Textile Sensor Assemblies

Disclosed is a sensor that includes a first textile assembly having a first conductive textile element and a first outer sheath that surrounds the first conductive textile element. The first outer sheath is formed from a first non-conductive material that is configured to transport moisture through the first outer sheath. The sensor includes a second textile assembly having a second conductive textile element and a second outer sheath that surrounds the second conductive textile element. The second outer sheath is formed from a second non-conductive material that is configured to transport moisture through the second outer sheath. The first and second outer sheaths are in contact with each other so as to maintain separation between the first conductive textile element and the second conductive textile element along a length of the sensor.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Wearable device and system for detecting user parameters

The invention discloses a wearable device and system. The wearable device comprises: a wearable main textile body, which comprises a plurality of interwoven or knitted yarns; one or more textile sensors, wherein each textile sensor is located at a respective region of the wearable main textile body and comprises a plurality of functional yarns integrally interwoven or woven with the yarns of the wearable main textile body at the region located; and an interface communicatively coupled with one or more than one of the textile sensors.

Owner:FIBRET (SHANGHAI) SMART TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com