Automatic cleaning machine and method for textile sensor metal comb

A technology of textile sensor and automatic cleaning machine, which is applied in the direction of metal processing equipment, grinding feed movement, grinding machine tool parts, etc., can solve the problems of high labor intensity and health injury of workers, achieve the effect guarantee and promote the development , the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

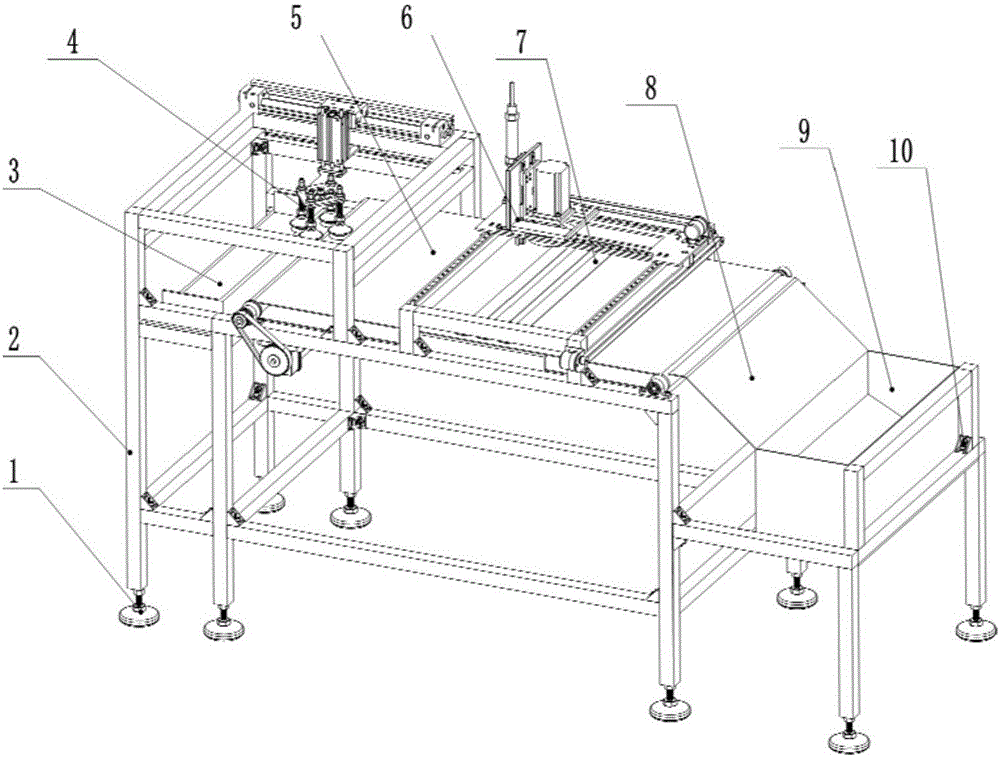

[0036] like Figure 1-7 As shown, a kind of textile sensor metal comb automatic cleaning machine of the present invention includes feeding system 4, conveying system 5, cleaning and polishing system 6, support 2, feeding box 3, discharging guide plate 8, discharging box 9, fixed angle piece 10,

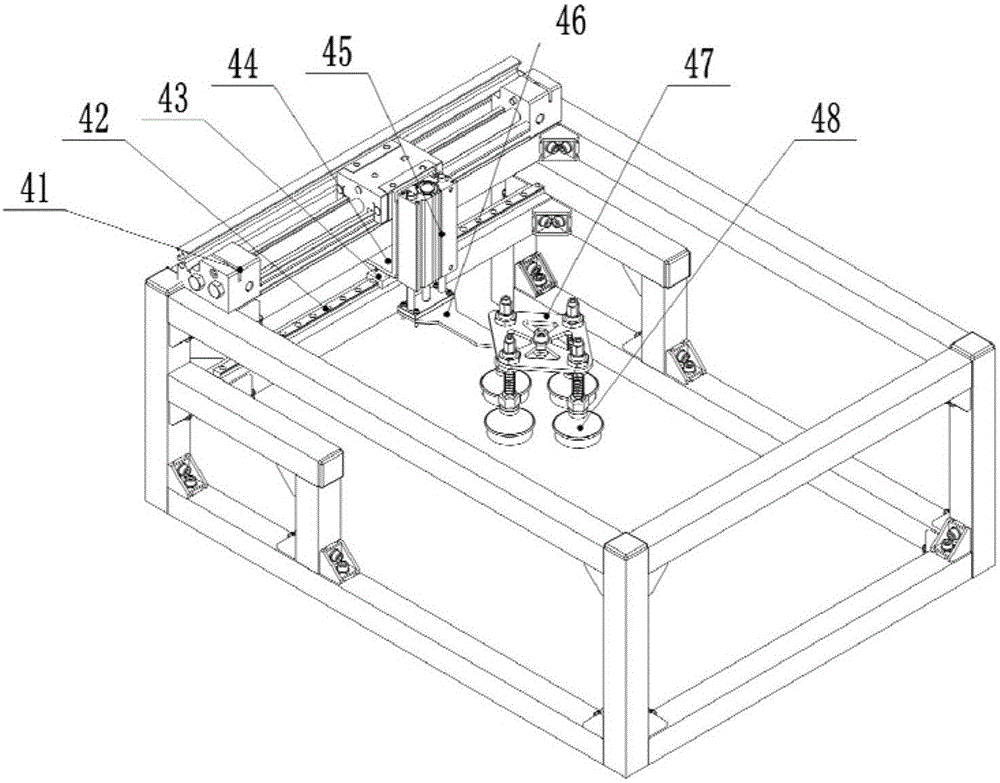

[0037] The feed system includes rodless cylinder 41, guide rail A42, slide block A43, L-shaped mounting plate 44, thin cylinder 45, pallet 46, vacuum suction cup frame 47, vacuum suction cup 48, and the rodless cylinder 41 of feed system 4 is fixed on On the bracket 2, the L-shaped mounting plate 44 is respectively fixed on the slide table of the barless cylinder 41 and the slide block A43 by bolts, the slide block A43 can slide left and right on the slide rail A42, and the thin cylinder 45 is installed on the side of the L-shaped mounting plate 44, A supporting plate 46 is fixed below the thin cylinder 45, a vacuum suction cup frame 47 is installed on the supporting plate 46, and 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com