Systems and method of assembling a tower section

一种组装系统、组装桁架的技术,应用在桁架塔架领域,能够解决复杂、困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

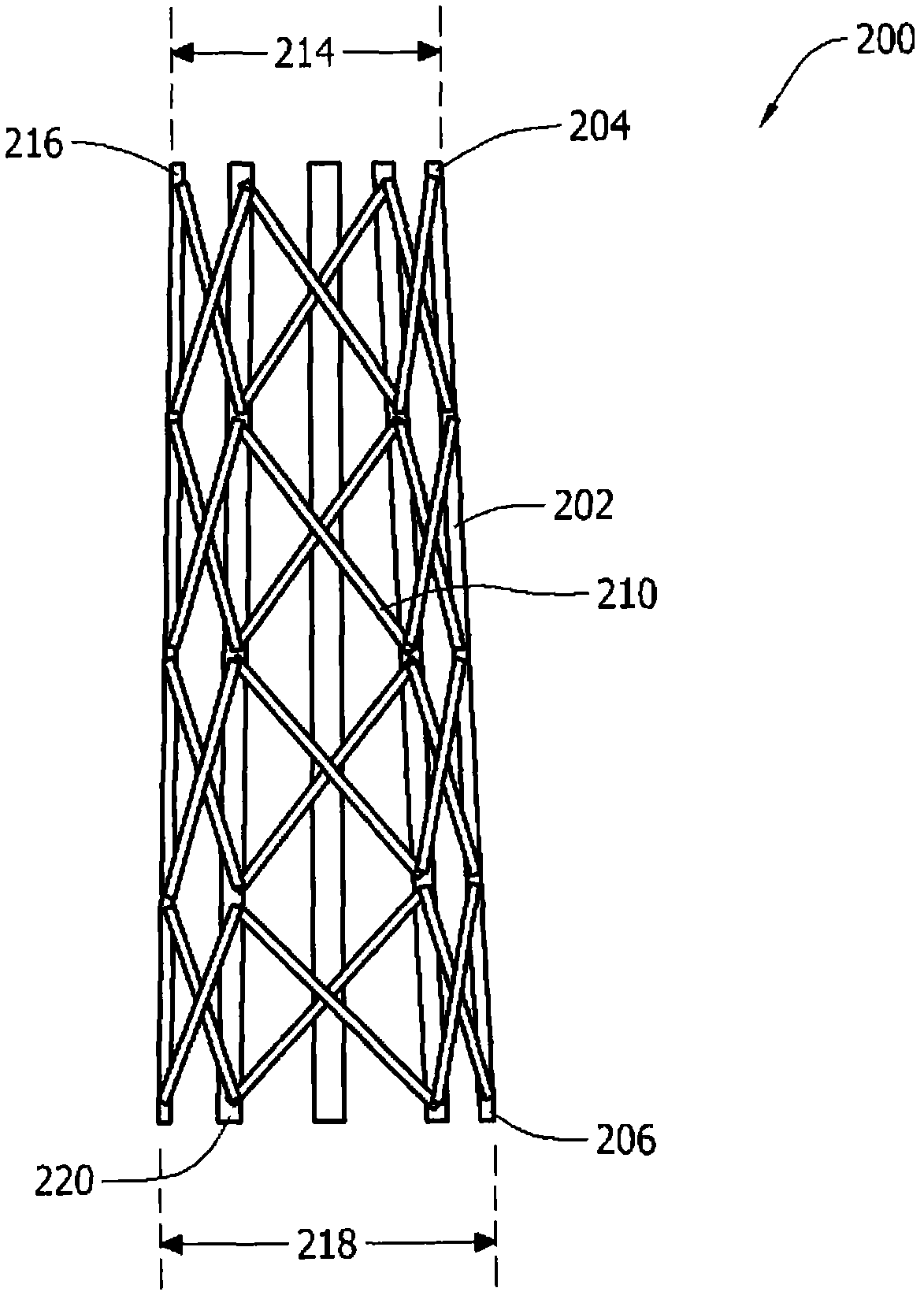

[0091] The systems and methods described herein facilitate the assembly of truss tower sections. In particular, utilizing the systems and methods described herein allows for more efficient assembly of truss tower sections in the field. Specifically, the systems and methods described herein assist in manipulating and assembling members of truss tower sections. Additionally, the systems and methods described herein are capable of assembling truss tower sections of various diameters and heights.

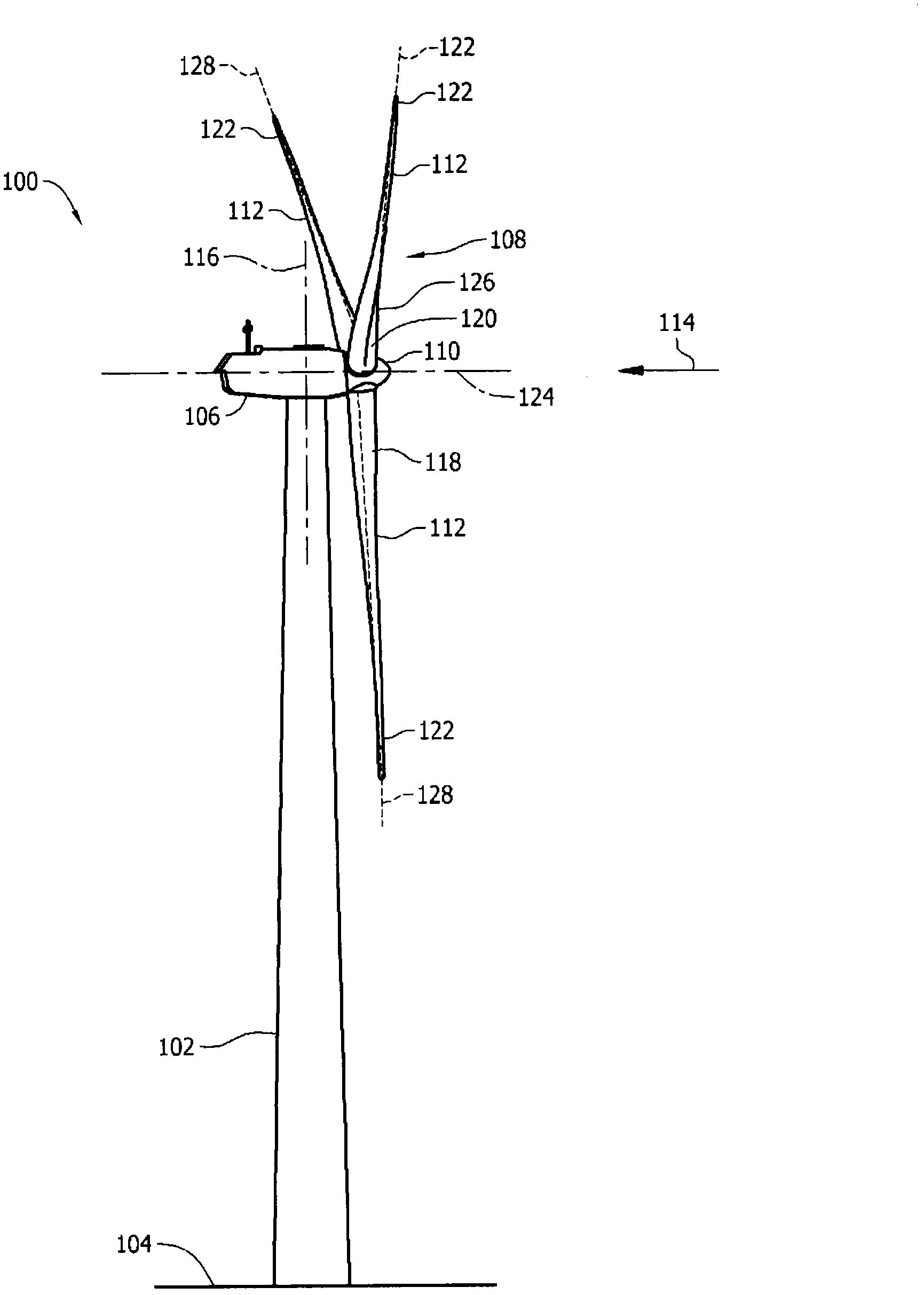

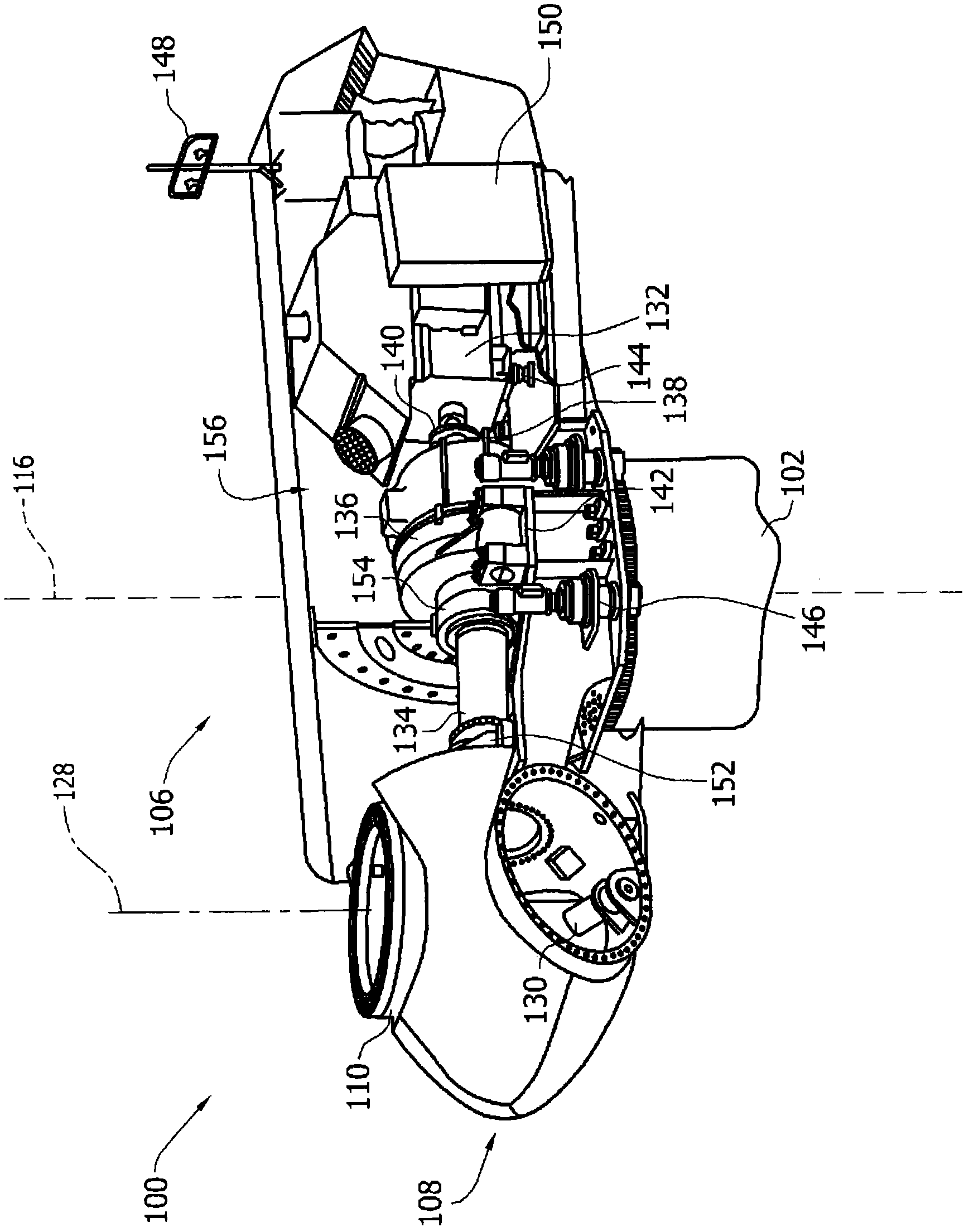

[0092] figure 1 is a schematic diagram of an exemplary wind turbine 100 . In the exemplary embodiment, wind turbine 100 is a horizontal axis wind turbine. Alternatively, wind turbine 100 may be a vertical axis wind turbine. In the exemplary embodiment, wind turbine 100 includes tower 102 extending from and coupled to support surface 104 . Tower 102 may be coupled to surface 104 using, for example, anchor bolts or through foundation mounts (neither shown). Nacelle 106 is coupled to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com