All-direction prestressing force antifatigue composite steel structure wind tower and installing method thereof

A prestressed, steel structure technology, applied in the installation/support of wind turbine configuration, wind power generation, etc., can solve the problems of low fatigue allowable stress range, low material utilization rate, etc., to achieve extended fatigue life, convenient construction, and materials used little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

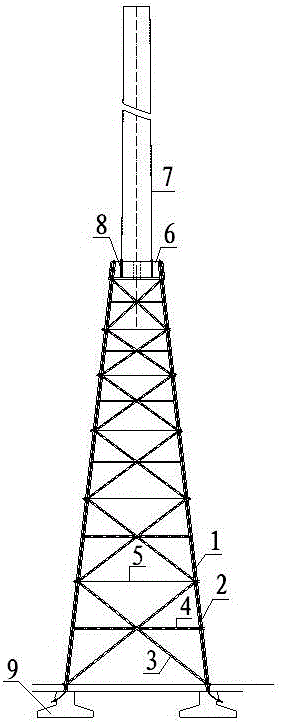

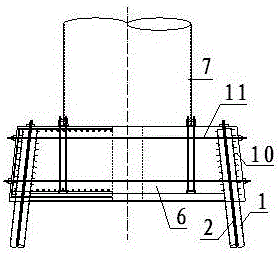

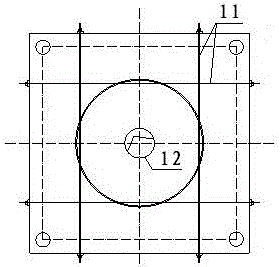

[0024] refer to Figure 1-Figure 4 , the omnidirectional prestressed anti-fatigue combined steel structure wind tower of this embodiment adopts a concrete transition section, and the wind tower includes a steel structure tower tube 7, a concrete transition section 6, a lattice tower frame and a base part 9, and the steel structure The tower tube is fixed in the concrete transition section 6, the concrete transition section 6 is located at the top of the lattice tower, and the lattice tower is installed on the foundation part 9, and the lattice tower includes a tower column 1, a prestressed Double steel strand 2, inclined bar 3, cross bar 4, and diaphragm 5. The prestressed double steel strand 2 penetrates from the bottom of the tower column 1 to the top, the bottom end is anchored in the base part 9, and the top end is tensioned and fixed on the At the top of the pylon, the oblique rods are fixed crosswise on the pylon, and the cross bars and diaphragms are fixed on the pylon ...

Embodiment 2

[0028] refer to Figure 5 , as the jacket in the offshore wind turbine foundation, after the construction is completed according to Step 1 to Step 3 of Embodiment 1, piles 13 are driven at the foot of the tower.

Embodiment 3

[0030] refer to Figure 4 , Figure 6-Figure 9 , the omnidirectional prestressed anti-fatigue combined steel structure wind tower of the present embodiment adopts a steel structure transition section, which includes a steel structure tower tube 7, a steel structure transition section 16, a lattice tower frame and a base portion 9, and the steel structure The structural tower 7 is connected to the top of the steel structure transition section 16, and the steel structure transition section 16 is located on the top of the lattice tower, and the lattice tower is installed on the foundation part 9, and the lattice tower includes tower columns 1. Prestressed double steel strand 2, inclined bar 3, cross bar 4, and diaphragm 5. The prestressed double steel strand 2 penetrates from the bottom of the tower column 1 to the top, and the bottom end is anchored to the cable of the base part 9 In the anchoring section 14 , the top end is tensioned and fixed on the top of the tower column 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com