Tower for a wind power station

A technology for wind energy equipment and towers, applied in mechanical equipment, wind power generation, towers, etc., can solve problems such as technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

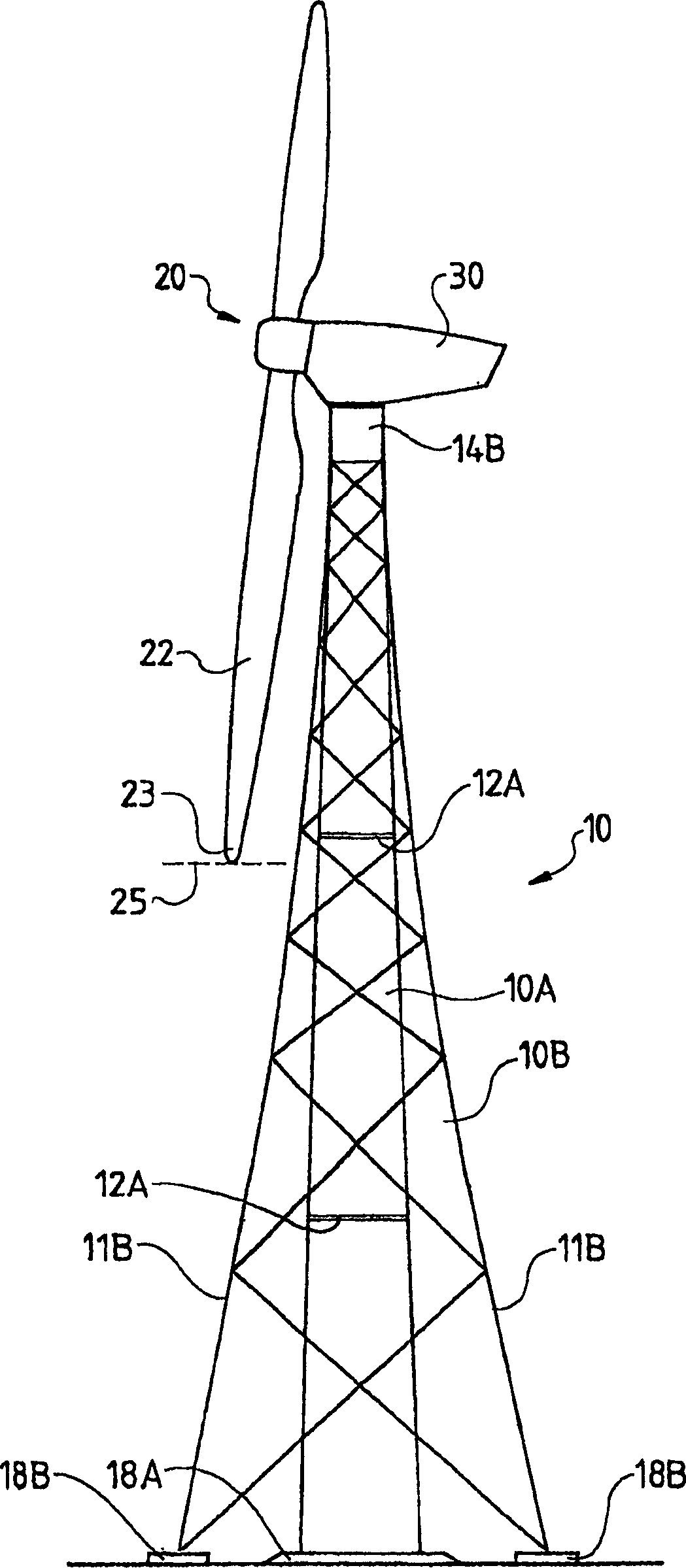

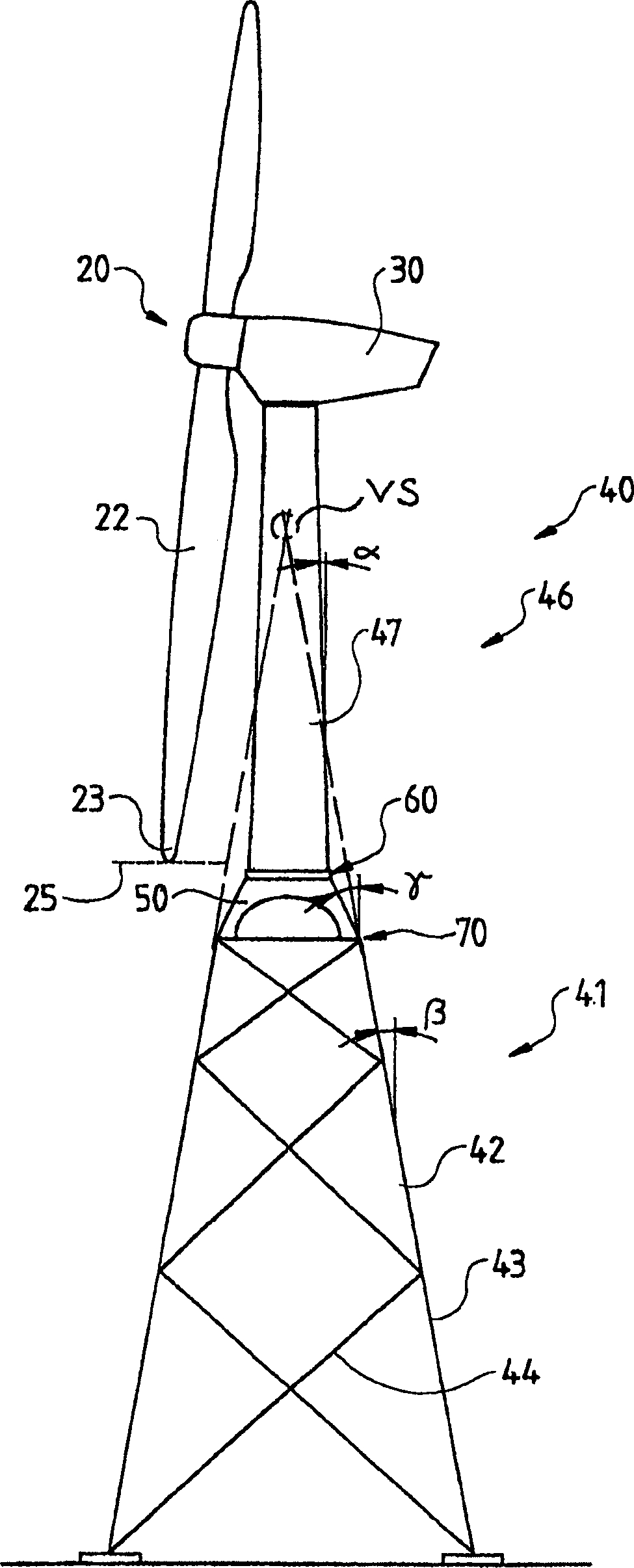

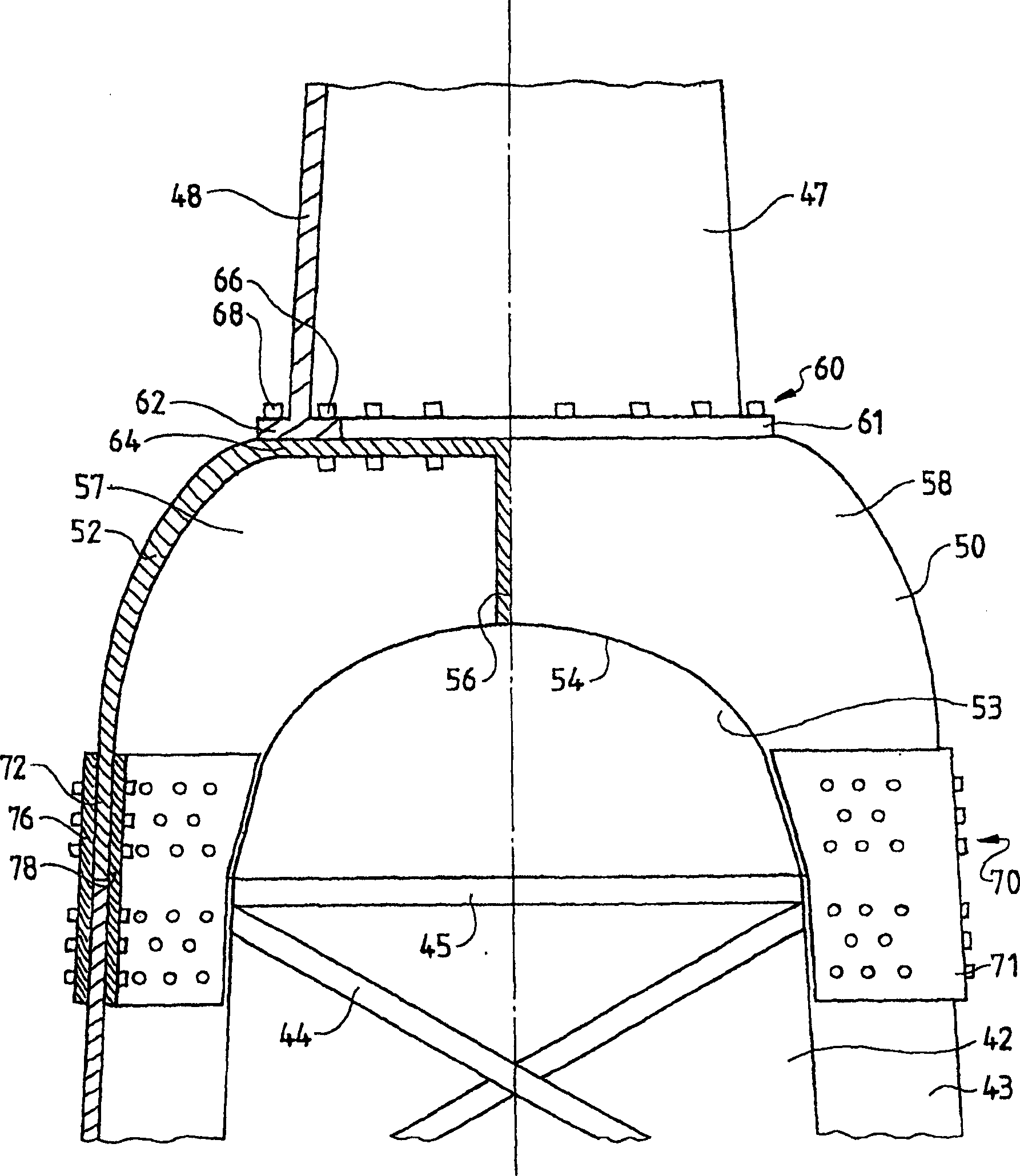

[0074] figure 1A wind energy installation according to the prior art is shown, in which two tower variants, namely a tubular tower 10A and a lattice tower 10B, are shown superimposed as supporting towers 10 . The tower 10 supports a machine nacelle (Maschinengondel) 30 rotatably fixed about a vertical tower axis, on which a machine including at least one blade tip 23 is supported rotatably about a substantially horizontal axis. The rotor blades 22 of the rotor 20 . The figure shows a design of a three-blade rotor, wherein the horizontal plane of the rotor tip 23 in the lower position is indicated by a dashed line 25 .

[0075] In addition to the rotor support, the machine nacelle 30 generally contains a generator, if necessary a transmission, a wind tracking system, various electrical components and other auxiliary systems. These components have not been shown for clarity of view.

[0076] The tubular tower 10A has a plurality of flange connections 12A for shipping reasons....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com