Efficient chemical raw material stirring cylinder

A technology for chemical raw materials and mixing drums, which is applied to mixer accessories, mixers with rotary mixing devices, chemical instruments and methods, etc., can solve the problems of complex structure, not easy to disperse, and single function, and achieves enhanced mixing efficiency and high efficiency. Efficiency, drag reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

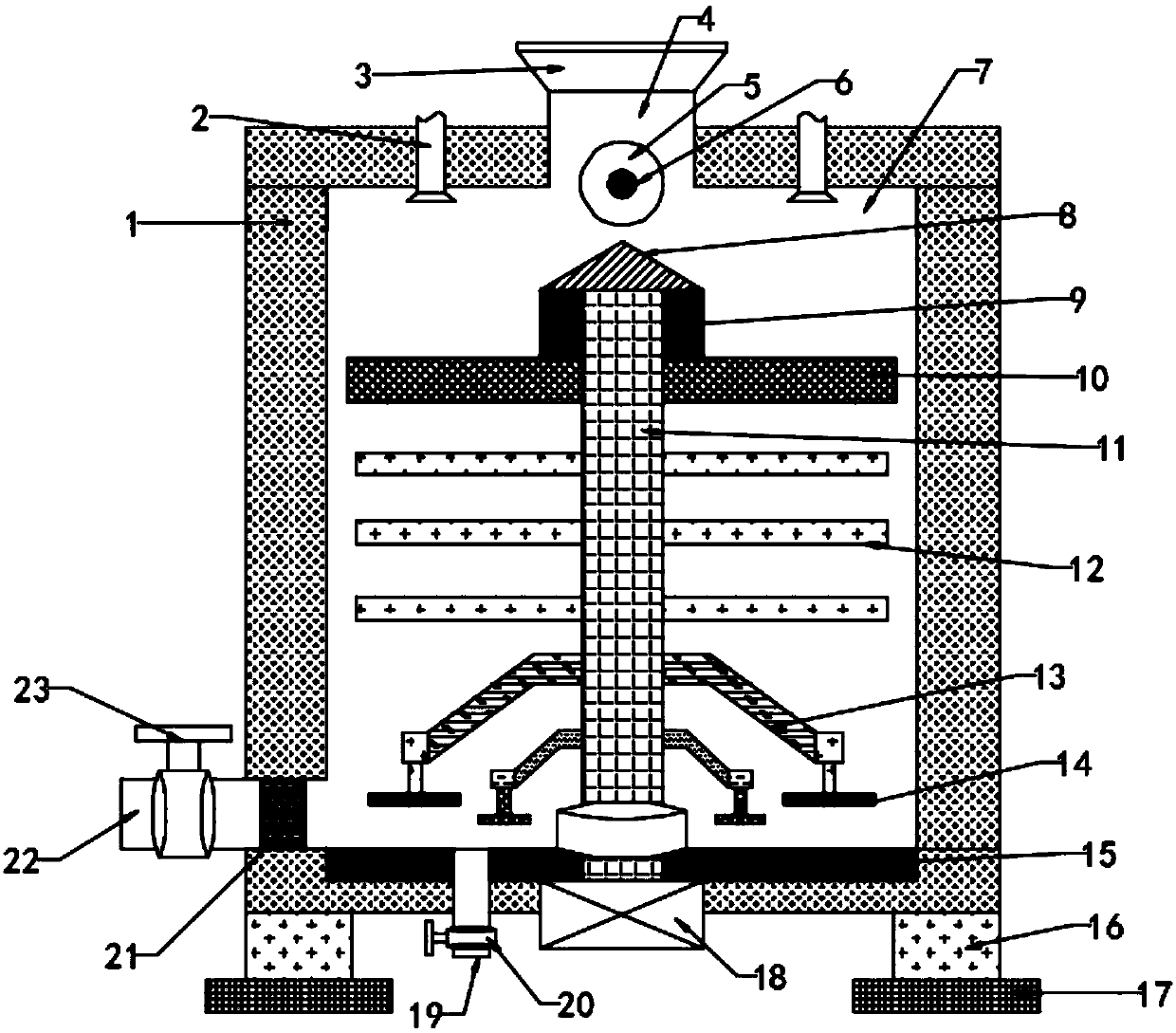

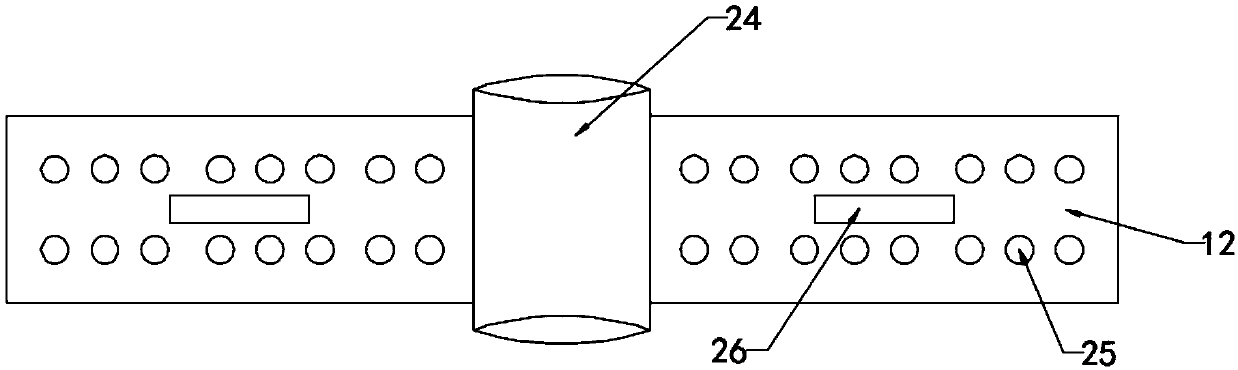

[0019] see Figure 1-2 , in the embodiment 1 of the present invention, a kind of high-efficiency chemical raw material mixing drum, it comprises: shell 1 and mixing drum inner chamber 7, described shell 1 upper end is provided with water inlet pipe 2 and feeding structure, and the quantity of water inlet pipe 2 is 2, the feeding structure is installed between the water inlet pipes 2, and the feeding structure is composed of a feeding hopper 3 and a feeding pipe 4 connected under the feeding hopper 3, and a distributor 5 is installed at the lower end of the feeding pipe 4, A fixed shaft 6 is arranged inside the feeder 5. When the chemical raw material enters the inner chamber 7 of the mixing drum from the feed hopper 3 through the feed pipe 4, the feeder 5 rotates due to the gravity of the chemical material, and the rotating feeder 5 rotates. The feeder 5 performs a material distribution function on the chemical raw materials to prevent the materials from being concentrated and...

Embodiment 2

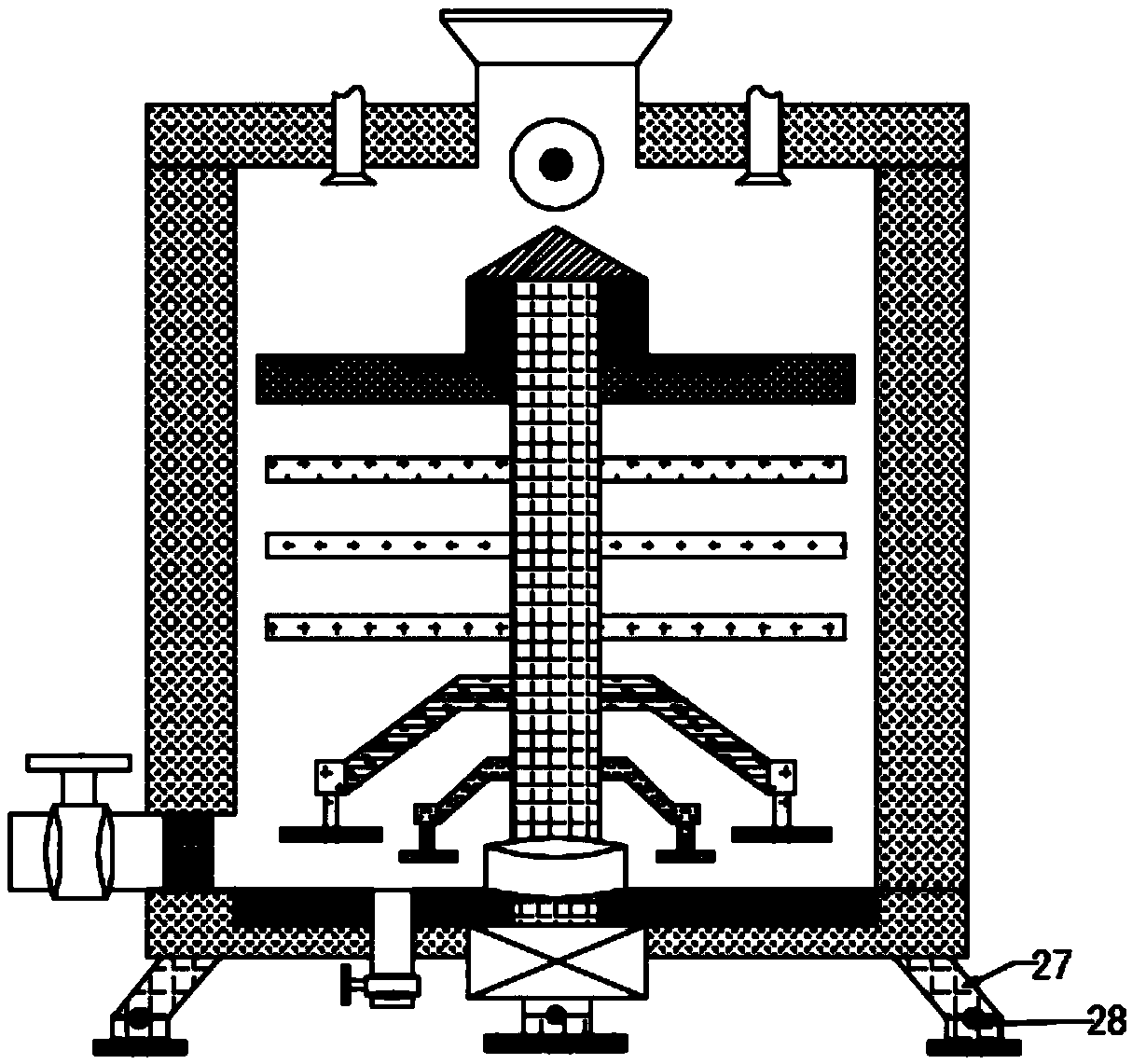

[0023] see image 3 , in the embodiment 2 of the present invention, a kind of highly efficient chemical raw material mixing drum, the embodiment 2 replaces the leg 16 under the shell 1 with the oblique leg 27, the number of the oblique leg 27 is 3, and the outer shell 1 is Triangular distribution, the oblique legs 27 are connected to the column through the fixing buckle 28, and the anti-skid pad 17 is arranged under the column. Compared with the embodiment 1, the stability of the embodiment 2 is better than that of the embodiment 1.

[0024] The working principle of the present invention is: when the chemical raw material enters the inner cavity 7 of the mixing drum from the feed hopper 3 through the feed pipe 4, due to the gravity of the chemical material, the feeder 5 is rotated, and the rotating feeder 5 is opposite to the chemical material. The raw material is divided into one material, avoiding the concentrated feeding of the material to the same area, and it is not easy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com