Inclusive single-use cooking apparatus

a single-use, cooking technology, applied in the direction of lighting and heating equipment, domestic stoves or ranges, climate sustainability, etc., can solve the problem that grilling is not particularly feasible for the last tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

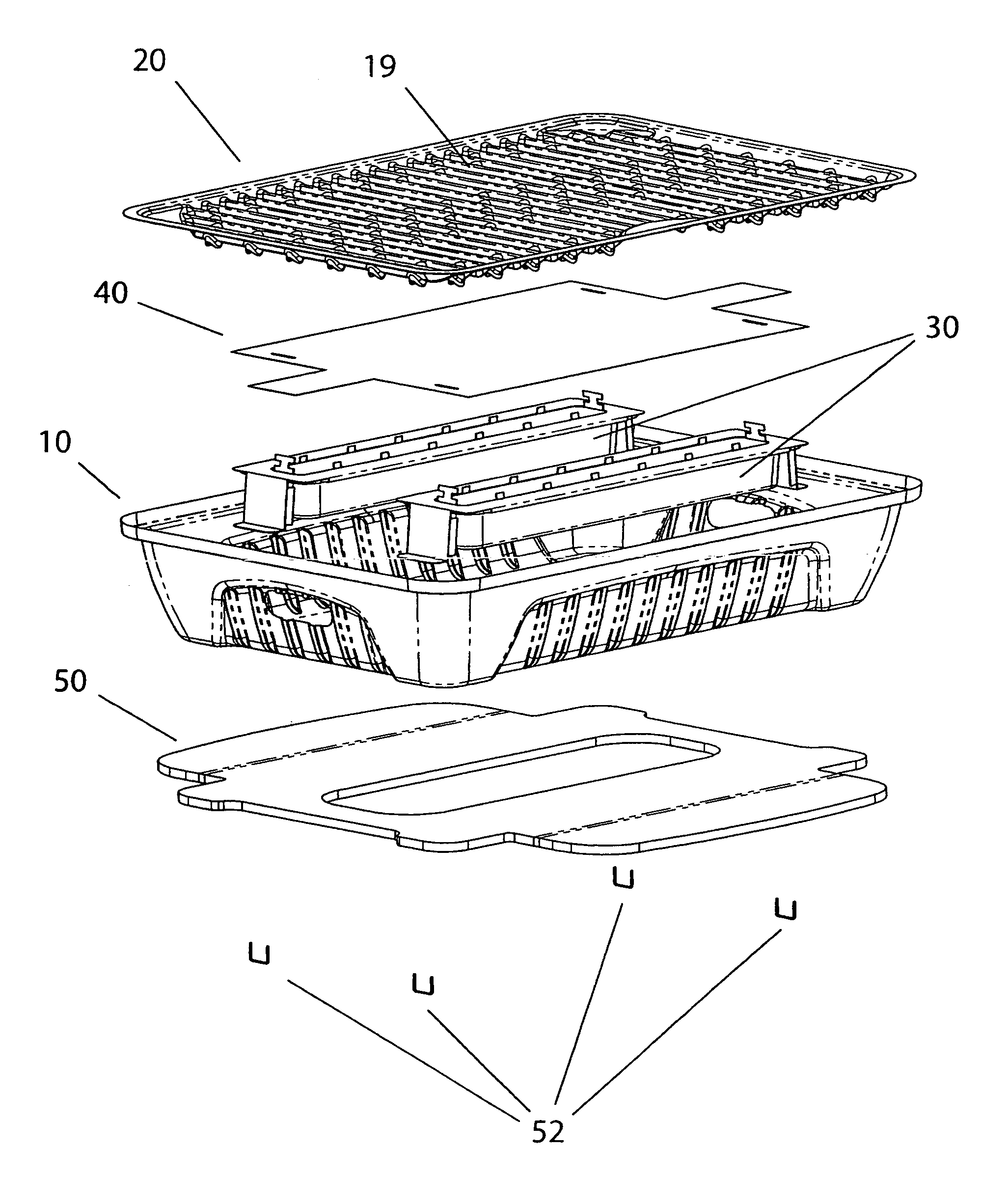

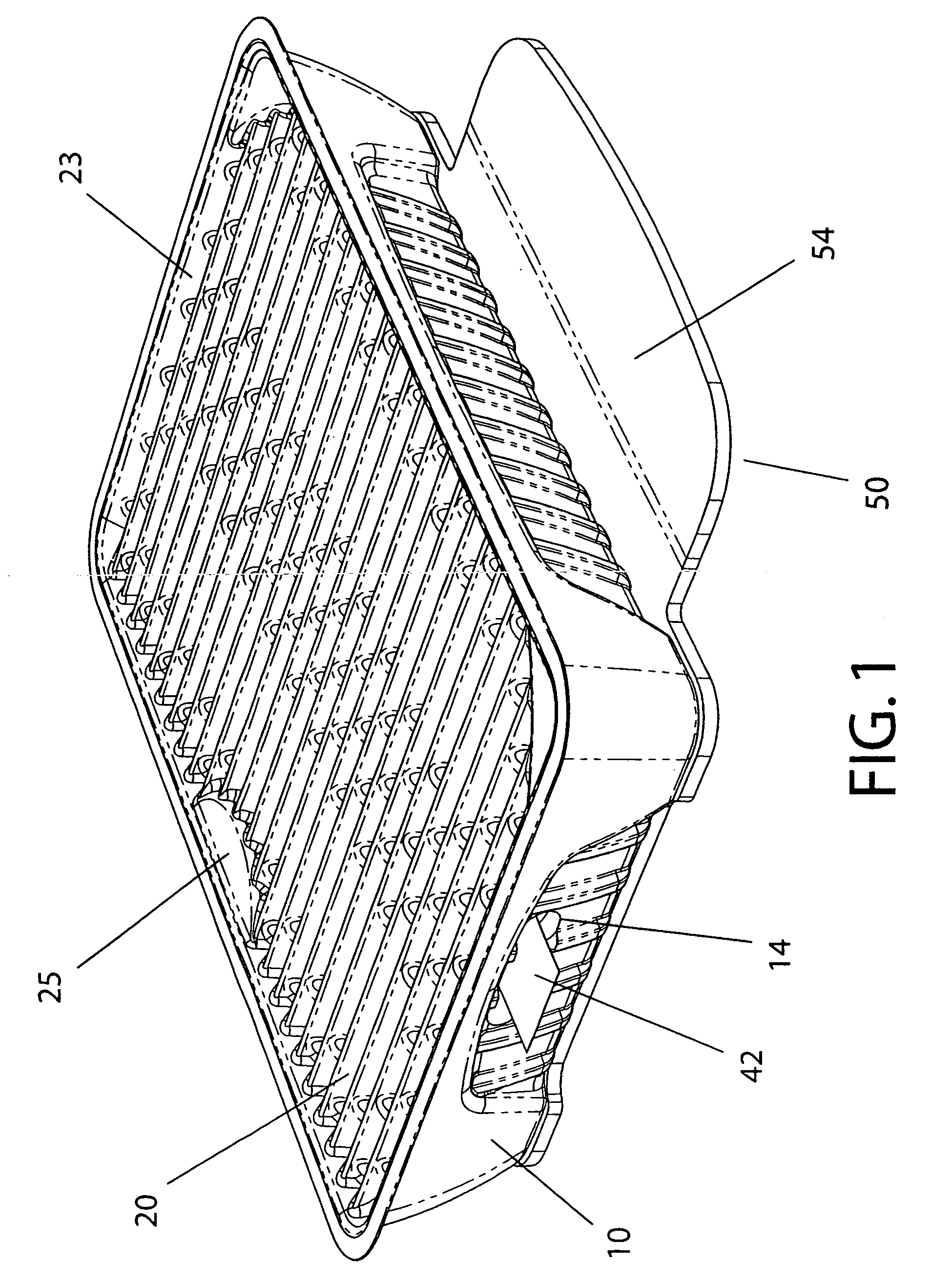

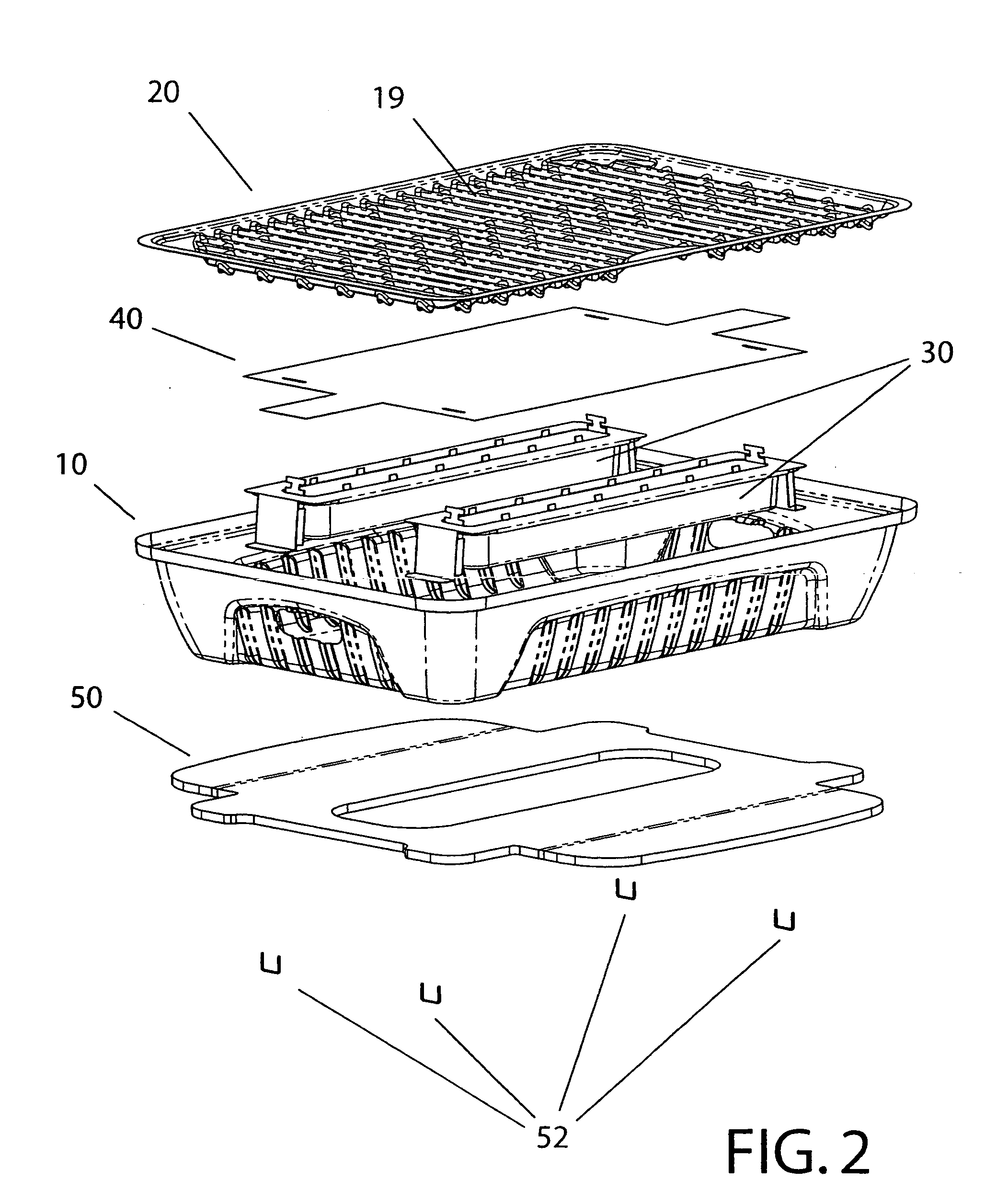

[0051] The present invention provides a single-use cooking assembly that utilizes a non-charcoal fuel source and is all-inclusive in nature. Suitably, the cooking assembly requires no additional components beyond food for a complete cooking session. Suitably, the fuel utilized is a gelled alcohol, which is clean-burning, inexpensive and requires the use of no intermediate tinder material to achieve self-sustaining combustion. In this way, the user may directly ignite the base fuel and does not have to wait for the heat source to reach a suitable temperature to begin cooking, which is otherwise typical with more traditional wood or charcoal fuels. This allows the user to experience very little delay between ignition and actual cooking.

[0052] In one embodiment, the fuel is housed within two thin-gauge metal fuel vessel assemblies. Each assembly comprises a fuel vessel, each fuel vessel being sealed with a metallized combustible and impermeable polymer film, referred to as the combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com